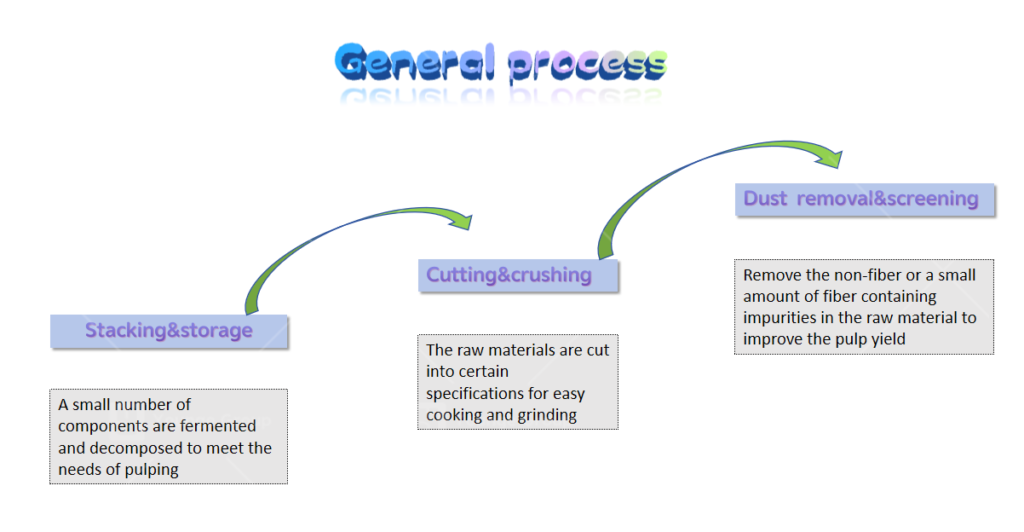

The material preparation section is an important part of the pulp and paper production process. It directly affects the product quality and production cost of the subsequent sections. In pulp and paper enterprises, it refers to the basic processes of stacking, storage, cutting, crushing, dust removal and screening of plant fiber raw materials used for pulp and paper.

The material preparation section can remove the bark and knots of wood raw materials, the spikes, sheaths, pith and dust, sand and gravel and other impurities of grass raw materials, and select qualified pieces as required, and then send them to the next section.

The material preparation process is also quite different for different types of raw materials. For example, the material preparation process for wood and grass raw materials is quite different.

Raw material storage

1.The purpose of storage

- Improve the quality of raw matarials

So why can storage improve the quality of raw materials?

This is because plant raw materials will be affected by weathering, fermentation and other natural effects after a period of storage, so that the moisture content gradually decreases and reaches a uniform balance with the environment. Storage of wood materials can reduce the content of some harmful components such as resin, stabilize the quality of raw materials, which is beneficial to subsequent pulping and can save the amount of chemicals used in subsequent chemical treatment.

For example, for Masson pine, after a period of storage, the occurrence of resin barriers can be reduced.

Grass raw material storage

After 4-6 months, due to the natural fermentation of starch, pectin, protein, fat, etc. in the raw materials, the intercellular layer and cell wall tissue are damaged to varying degrees, so that the amount of chemicals used is reduced compared to steaming new grass, the chemical solution is easier to penetrate, and the lignin is easier to remove.

However, if stored improperly, it will cause mold and deterioration, and even cellulose will degrade, ash content will increase, leading to negative production effects

- Ensure production requirements

As papermaking enterprises become larger and more continuous, more and more plant raw materials are used every day, so there must be enough raw materials.

For grass raw materials, due to seasonal restrictions on acquisition, such as wheat straw, the acquisition cycle in China is about 3-5 months, mainly concentrated from November to April of the following year, so the raw materials needed for production during the rest of the time are storage raw materials.

Generally, the storage period of grass is more than 6 months, and that of wood raw materials is generally 3-6 months.

If you need to produce high-quality pulp, you need a longer storage period, about 10-12 months.

2.Requirements for raw material factories

Generally, large enterprises have two raw material sites, one inside the factory and the other outside the factory. The raw material plant outside the factory is generally located near the raw material production site;small enterprises generally only set up raw material sites inside the factory.

Requirements

- Requirement 1: Fire safety measures

Raw materials are flammable and have serious consequences. In addition to human factors, spontaneous combustion caused by fermentation and fires caused by lightning strikes must be prevented. - Requirement 2: Convenient transportation

Generally speaking, 2-3 tons of raw materials are required to enter and exit the raw material plant to produce one ton of paper. Therefore, the transportation volume of the raw material plant accounts for more than 50% of the total transportation volume of the plant, so the transportation route must be unobstructed and convenient. - Requirement 3: Unobstructed drainage

In order to avoid mildew and water accumulation in the raw material plant affecting the stability of the stack base, water accumulation is not allowed in the raw material plant after rain, and drainage must be unobstructed. - Requirement 4: Good ventilation

If the ventilation is not good, especially for grass raw materials, the heat generated by fermentation may cause spontaneous combustion of the stack.

The direction of the stack is preferably at a 45-degree angle to the perennial wind direction. - Requirement 5: Composite lighting requirements

The work of the raw material plant at night requires good lighting, and at the same time, it is necessary to avoid fires caused by unreasonable laying of lighting circuits.

Methods of collecting, transporting and storing raw materials

1.Harvesting for wood

The harvesting and transportation of wood raw materials refers to the removal of treetops and branches after the trees in the forest are felled, and then sawing them into wood sections of a certain length, about 6 meters.

2.Storage for wood (Water storage/Ground storage)

(1)Water storage

In hot and humid areas, wood is prone to rot and deterioration due to the warm and humid climate. At the same time, there are abundant water resources in rivers, lakes and other places, so water storage can be used. Water storage can save the heavy handling operations with the help of water buoyancy, improve work efficiency, and make the moisture of wood uniform to prevent rot. However, water storage also has disadvantages such as the difficulty of degrading log resin and the pollution of water bodies by wood extracts.

(2)Ground storage

Dry areas have a dry climate and wood is not easy to rot, so most of them are stored on the ground.

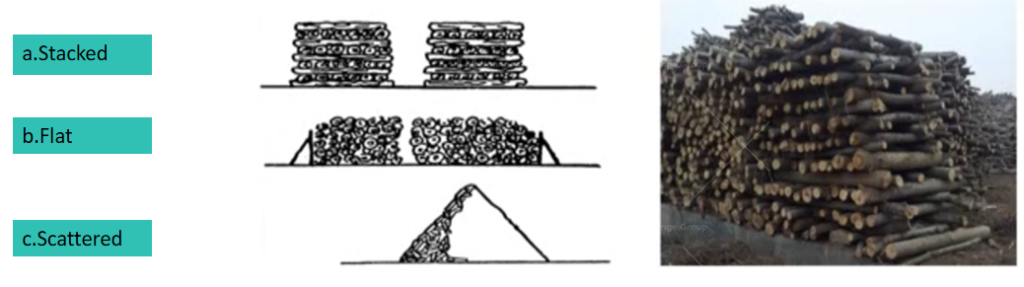

There are generally three types of stacking methods for ground storage of wood raw materials: stacking, parallel arrangement and loose stacking.

Stacking method: Stack the logs in a crisscross pattern, suitable for long logs.

Flat method: Stack the logs in a straight pattern, suitable for long or short logs.

Scattered method: Stack the raw materials naturally, suitable for wood chips, slabs or short logs.

At present, factories often use a combination of parallel stacking and stacking methods, that is, stacking methods are used at both ends and parallel stacking methods are used in the middle. This method makes the stacking more stable and also ensures a higher stacking density.

3.The harvesting and storage of non-wood materials

(1)Harvesting

The characteristic of non-wood raw materials:

- It is large in size, light and loose, and has scattered origins;

- It has many impurities and other characteristics

Therefore, packing is necessary after harvesting.

(2)Storage

For example, straw, wheat straw, reed and other grass materials are generally stored in straw house-type stacks. Bagasse is stored in pyramid-shaped stacks.

For more infos , pls ref video below: