Pulping is the process of using chemical or mechanical methods, or a combination of both, to dissociate plant fiber raw materials into natural pulp (unbleached pulp) or bleached pulp. The main function of pulping is to provide high-quality pulp for papermaking and other fiber processing industries.

Pulping methods can be divided into chemical methods and high-yield methods.

A.Chemical pulping refers to the process of using chemical agents to treat plant fiber raw materials under specific conditions to dissolve most of the lignin (Lignin) and separate the fibers into pulp. Chemical pulping methods include various alkali methods and sulfite methods.

B.High-yield pulping refers to pulping methods with high yields, which can be divided into mechanical methods, chemical mechanical methods and semi-chemical methods according to the degree of mechanical treatment.

In these pulping processes, lignin is retained as much as possible, so that more pulp can be obtained from each cubic meter of wood raw materials, thereby improving the utilization efficiency of raw materials. Therefore, high-yield pulping has a higher pulp yield than chemical pulping.

The yield of chemical pulping is about 40-50%,

the yield of semi-chemical pulping is 65-85%,

the yield of chemical-mechanical pulping is about 85-90%,

and the yield of mechanical pulping can be as high as 90%-98%, which is nearly 1 times that of chemical pulping.

High Yield Pulp

Depending on the different chemical and mechanical treatment processes, various high yield pulping methods produce different high yield pulps (High Yield Pulp, HYP).

Category

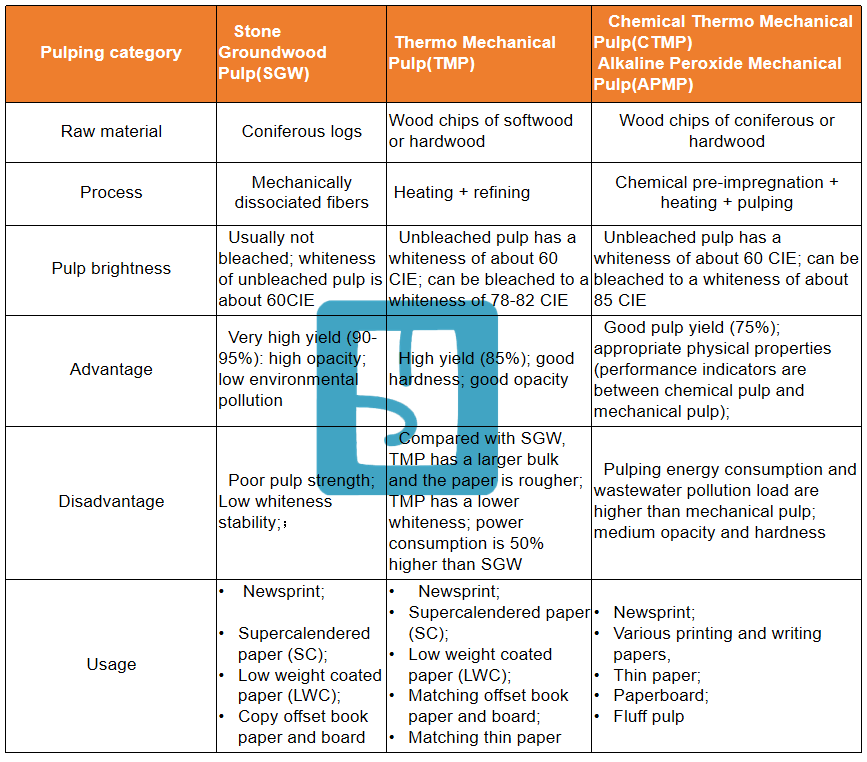

In this article, we focus on introducing several typical high yield pulps:

1. Stone Groundwood Pulp (SGW) and Thermoechanical Pulp (TMP) in mechanical pulping.

2. Mechanical pulping after chemical pretreatment: common chemical thermomechanical pulp (CTMP) and alkaline peroxide mechanical pulp (APMP).

Detailed introduction

1.Stone Groundwood Pulp, SGW

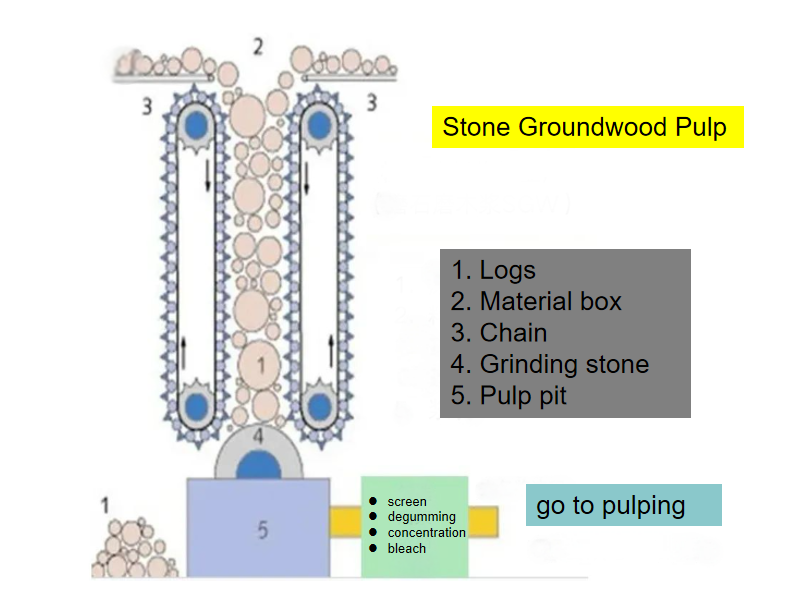

Stone Groundwood Pulp (SGW) is the pulping method with the highest yield, lowest production cost and least environmental pollution among all pulp types. However, it is limited by raw materials and can only use logs (Wood Logs) instead of wood chips (Wood Chips), and usually uses coniferous wood (Softwood). The high cost of raw material logs has made SGW technology disappear. On the contrary, other high-yield pulping methods can use wood chips from sawmills, and the cost of raw materials is much lower.

The figure below is a schematic diagram of a chain grinder. Its main principle is to use the winged chain that circulates on both sides of the material box above the grinder to press the log to the grinder. This chain grinder has a relatively stable motor load, is convenient for spraying water and carving stones on the grinder, and is relatively easy to remove pulp and wood chips from the grinding area. The main disadvantage is that the equipment occupies a large space and the chain fins are easily damaged.

schematic diagram of a chain grinder

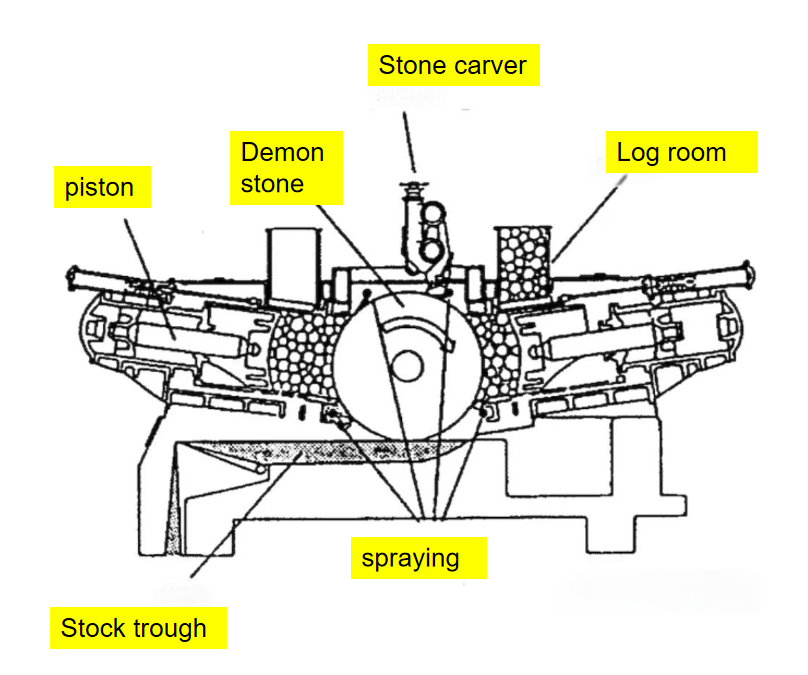

The pressure grinder increases the pressure between the wood chips and the grinding stone through the piston, which improves the uniformity of pulp quality, increases the proportion of long fiber components, and improves the tensile strength and tear resistance of pulp. Compared with the chain grinder, this pressure grinder is more prone to clogging, making it more difficult to operate.

Schematic diagram of pressure wood grinder

SGW has the disadvantages of insufficient strength and low whiteness stability because it retains a large amount of lignin, but it has excellent opacity and ink absorption, very good bulk and dimensional stability.

2.Thermo Mechnical Pulp,TMP

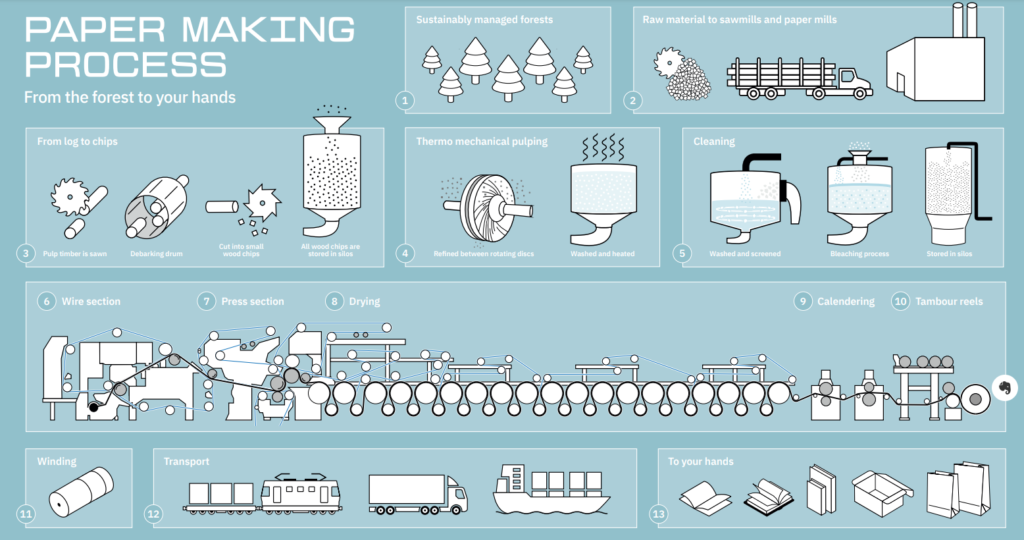

The biggest difference between Thermo Mechanical Pulp (TMP) and SGW is that TMP uses lower-cost wood chips as raw materials and no longer requires logs. Its production process consists of wood chip washing, wood chip preheating, spiral feeding, disc refiner refining, screening, etc.

This picture is from holmen.com

The most critical steps are:

- Preheat the wood chips in 115-135°C steam for 2 to 5 minutes.

- Refining is the most critical step. The preheated wood chips are fed into the disc refiner through a double screw conveyor for refining. It can be one or two stages of refining. The softened wood chips are dissociated into fine fibers through mechanical action. The figure below is a high-consistency disc refiner in the ATMP (Advanced TMP) technology launched by Younge.

The biggest difference between Thermo Mechanical Pulp (TMP) and SGW is that TMP uses lower-cost wood chips as raw materials and no longer requires logs. Its production process consists of wood chip washing, wood chip preheating, spiral feeding, disc refiner pulping, screening, etc.

The most critical steps are:

Preheat the wood chips in 115-135°C steam for 2-5 minutes.

Refining is the most critical step. The preheated wood chips are fed into the disc refiner for pulping through a double screw conveyor. It can be one or two stages of pulping. The softened wood chips are separated into fine fibers through mechanical action. The figure below is a high-consistency disc refiner in the ATMP (Advanced TMP) technology launched by Andritz.

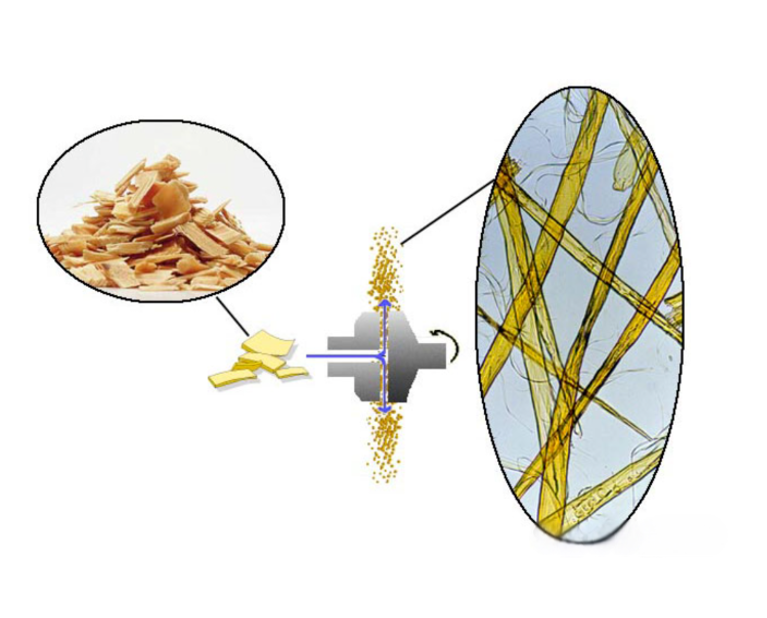

After screening, deslagging and concentration, the pulp after pulping usually undergoes a final grinding, namely “pulping fine grinding”, to reduce the content of fiber bundles in the pulp. The figure below is a schematic diagram of wood chips becoming fibers after being refined by a disc refiner.

schematic diagram of wood chips becoming fibers after being refined by a disc refiner

3. Chemical Thermo Mechanical Pulp ,CTMP

Chemical Thermomechanical Pulping (CTMP) is developed on the basis of TMP. The main difference from TMP is the addition of a chemical pre-impregnation section.

- The production process includes the following key steps:

Chemical pre-impregnation treatment mainly uses sodium sulfite. When producing hardwood CTMP, a certain amount of sodium hydroxide needs to be added to impregnate the wood chips; - Steam preheating of wood chips. Depending on the type of wood chips and the equipment, the heating temperature of coniferous wood is 120-135oC, while the heating temperature of hardwood is lower, 60-120oC. The pre-impregnation time is generally 2-5min.

- Pulping: one or two stages of pulping, this process is the same as TMP.

Chemical pre-impregnation is the main feature of CTM and is also a key process for producing CTMP. Under mild conditions, the main function of chemical treatment is to soften the fibers. After the wood is softened, more complete fibers can be separated, and the long fiber components are increased. The softened fibers help reduce the energy consumption of pulping and improve the strength of pulp.

When producing paper products with higher whiteness requirements, the whiteness of the paper can be improved by subsequent bleaching of the CTMP pulp, namely bleached chemithermomechanical pulp (BCTMP).

4.Alkaline Peroxide Mechanical Pulp,APMP

Alkaline hydrogen peroxide chemimechanical pulp (APMP) is developed on the basis of bleached chemithermomechanical pulp (BCTMP). Its biggest feature is that pulping and bleaching are combined and completed at the same time, while avoiding the problems caused by the use of sulfur-containing products (such as sodium sulfite in traditional CTMP pulp), especially its unique odor.

The key process steps of APMP include:

- Chemical pre-impregnation with sodium hydroxide (NaOH) and hydrogen peroxide (H2O2), and adding some additives at the same time. The amount of NaOH and H2O2 is the main factor affecting the quality of pulp.

- In order to prevent H2O2 from thermal decomposition, the pre-impregnation temperature is generally 60-80°C. The pre-impregnation time should be able to ensure that the raw materials are evenly and fully impregnated, generally 30-60 minutes.

- Refining: Generally, two-stage refining is used. At present, the common refining combination is the first stage high-concentration refining and the second stage low-concentration refining. The second stage low-concentration refining replaces the traditional high-concentration refining, mainly to reduce power consumption and reduce costs.

Notes:

Comparative studies of poplar APMP and BCTMP show that poplar APMP has lower chemical and energy consumption than the corresponding BCTMP. At the same beating degree, the bursting resistance, tensile strength and tear resistance of paper made from poplar APMP are slightly better than BCTMP.

5.Preconditioning-Refiner Chemical Alkaline Peroxide Mechanical Pulp,P-RC APMP

P-RC APMP is a high-yield pulping process developed on the basis of APMP. P (Preconditioning) means pretreatment before pulping, and RC (Refiner Chemical) means the chemical action of the grinding disc to promote the pulp.

P-RC is different from APMP in two characteristics:

- Chemical treatment of wood chips in the prepreg stage;

- The main bleaching reaction is carried out in a high-concentration reaction tower. Pulp bleaching replaces wood chip bleaching, overcoming the incomplete bleaching of APMP.

Comparison of high yield pulp

The biggest difference between SGW and other high-yield pulps is that the raw materials used are logs, not wood chips. The advantages of SGW and TMP are higher yields, but insufficient whiteness, and the fibers are too hard, which may affect the texture of the paper. Therefore, SGW and TMP are rare.

CTMP and APMP can use coniferous or hardwood wood chips as raw materials, and combine chemical treatment, heating and pulping processes to provide good yields and appropriate physical properties, while making full use of wood chip raw materials and being more environmentally friendly. Its disadvantage is that the opacity and hardness of the pulp are at a medium level.

Chemical pulping

Chemical pulping is the process of treating plant fiber raw materials with chemical agents under specific conditions to dissolve most of the lignin and separate the fibers into pulp.

There are two most common chemical pulping methods: one is sulfate pulping, and the pulp produced is called sulfate pulp (also known as kraft pulp), and the other is sulfite pulping, which is correspondingly called sulfite pulp.

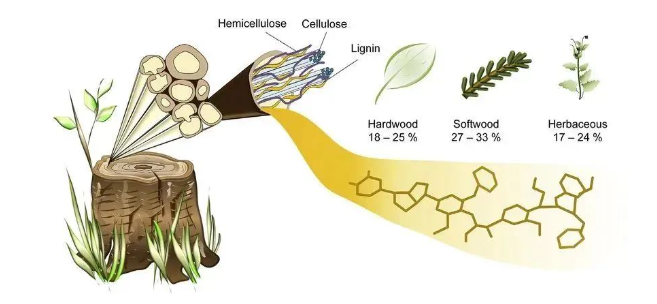

The biggest difference between high-yield pulp and chemical pulp is the extent to which lignin is retained. Chemical pulp removes lignin as much as possible, so the yield of pulp is relatively low, and the yield of chemical pulping is about 40-50%. The lignin content in hardwood is about 18-25%, the lignin content in coniferous wood is about 27-33%, and the lignin content in grass plants is lower, about 17-24% (as shown in the figure below).

The process of treating plant fiber raw materials with chemical agents at a certain temperature is often called cooking. The chemical agents used are called cooking liquid. The main purpose of cooking is to remove lignin and separate fibers from each other, but chemical agents will also degrade and dissolve cellulose and hemicellulose, which directly affects the yield of pulp and the strength of pulp. Therefore, it is necessary to reduce and prevent the degradation of carbohydrates as much as possible.

The cooking process is a complex, multi-phase, multi-compound chemical reaction process and a complex physical and chemical change process.

Kraft pulping

Kraft pulping was invented in the late 19th century. In 1890, Sweden built the world’s first kraft pulp mill. Kraft pulping is the most common method of chemical pulping, and kraft pulp accounts for more than 80% of chemical pulp.

To produce 1 ton of unbleached kraft pulp, needed:

- 2.4 tons of wood

- 10-20 kg of calcium carbonate (CaCO₃)

- 20-30 kg of sodium sulfate (Na₂SO₄) (this is also the origin of the name of kraft pulping)

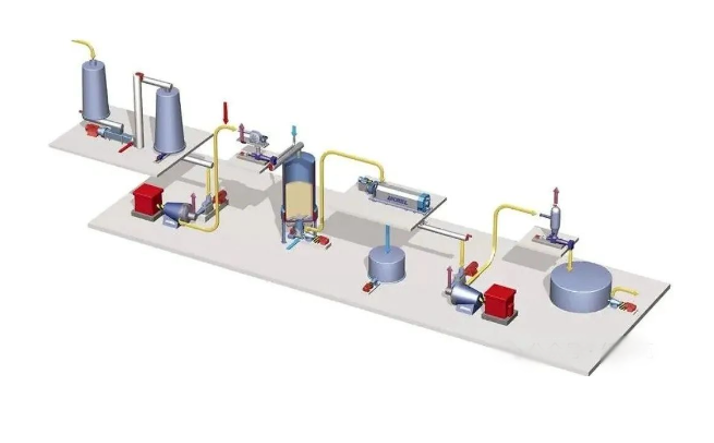

- An investment of up to hundreds of millions of euros (investing in the construction of a kraft pulp mill as shown in the figure below requires about 200 million euros)

It can be seen from this that kraft pulping is a pulping method with low daily operating costs but high one-time investment costs.

The kraft pulping system includes the cooking process from wood to pulp and a complex alkali recovery system (as shown in the figure below). The cooking liquor is made up of white liquor, black liquor and water according to the set concentration. Its main chemical composition is NaOH and Na2S. In addition, it also contains some impurities from the alkali recovery system, such as Na2CO3, Na2S04, Na2SO3, Na2S203 and CaCO3. The so-called alkali recovery is actually the recycling and reuse of expensive raw materials Na2S and NaOH.

Schematic diagram of the kraft pulping process and alkali recovery system

The rate and degree of delignification by cooking are closely related to the degree of penetration of the cooking liquid into the wood chips and the cooking technical process conditions, such as the composition, dosage, liquid ratio, maximum cooking temperature, heating and holding time curves of the chemicals.

Sulfite pulping

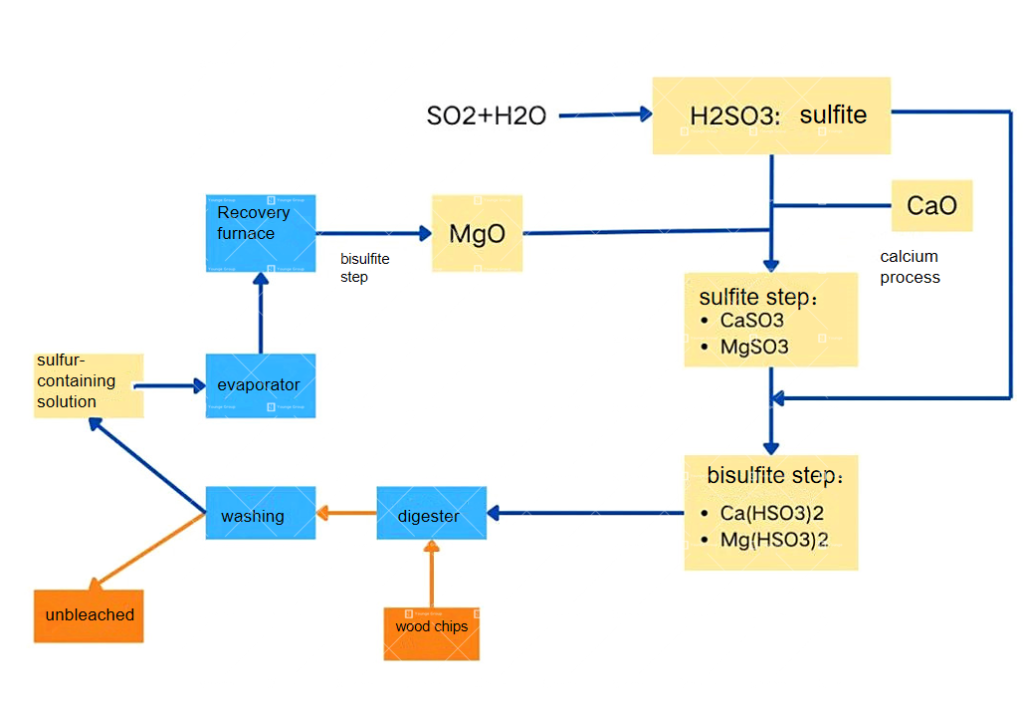

The two most common types of sulfite pulping are neutral and acid sulfite pulp.

1.Neutral sulfite pulp has a pH between 5 and 7. At this pH, lignin is not easily dissolved by the sulfite solution, so the wood chips must be treated mechanically before chemical treatment, and these pulps are called semi-chemical pulps.

2.Acid sulfite pulp has a pH between 3 and 5. The chemicals used are calcium and magnesium bisulfite. Recycling the magnesium salts is possible, but recycling the calcium salts is extremely difficult. Below is the cooking process from wood to pulp and the complex chemical recovery system:

Schematic diagram of the sulfite pulping process and chemical recovery system

Acid sulfite pulp mills can recover up to 80% of chemicals using the magnesium process. On the other hand, magnesium oxide (MgO) is much more expensive than quicklime (CaO).

Comparison of the two pulping methods

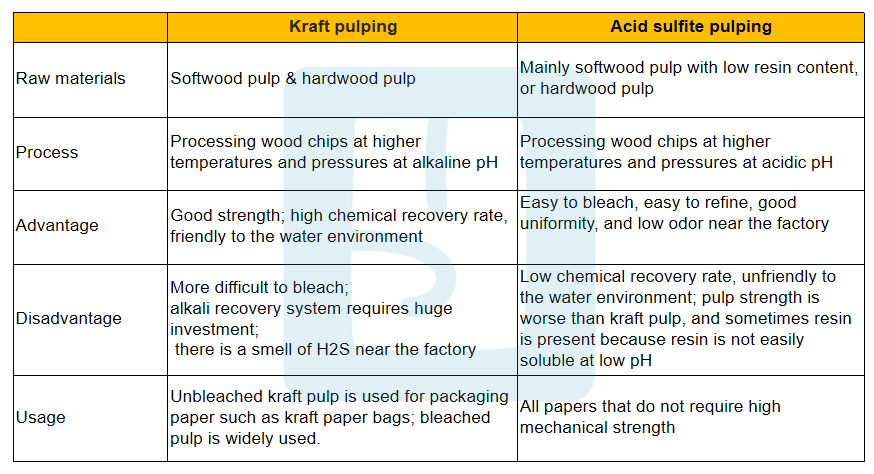

The following table compares kraft pulping and acid sulfite pulping:

Generally speaking, the cost of kraft pulping is lower than that of acid sulfite pulping, but it is not absolute and depends on the market supply and demand of pulp.