Introduction

In the vast and complex field of papermaking, the drying section is a crucial link, and the dryer fabric is the core component of the drying section. The performance and cleanliness of the dryer fabric directly affect the quality of paper, production efficiency and the stability of the entire papermaking process. With the continuous development of the papermaking industry, the demand for dryer fabric cleaners has become increasingly prominent. A high-quality papermaking dryer fabric cleaner can become a key factor for papermaking companies to improve production efficiency, reduce costs and improve product quality.

Importance of dryer fabrics and pollution issues

The role of the dryer in the papermaking drying section

The main function of the papermaking drying section is to reduce the moisture content of the paper by evaporating water so that the paper reaches the specified dryness. The dryer plays an important role in supporting and transmitting the paper in this process. It needs to have good air permeability, strength and stability to ensure that the paper can be evenly heated and dried during the drying process to avoid quality problems such as deformation and cracking of the paper. At the same time, the good performance of the dryer also plays an important role in maintaining the stable operation of the drying section, reducing downtime and improving production efficiency.

Pollution challenges faced by the dryer

During the papermaking process, the dryer in the drying section will be attacked by a variety of pollutants.

The first is fiber scraps. During the forming and transmission process of the paper, some fibers will fall off and adhere to the dryer. Over time, the accumulation of these fiber scraps will block the pores of the dryer, reduce the air permeability of the dryer, and affect the drying efficiency.

The second is oil pollution. Oil pollution from the lubrication system, transmission parts, etc. of the papermaking equipment may be contaminated on the dryer. Oil stains not only affect the appearance quality of the paper, but also reduce the hydrophilicity of the dryer fabric, making it impossible for water to effectively penetrate the dryer fabric, resulting in uneven drying.

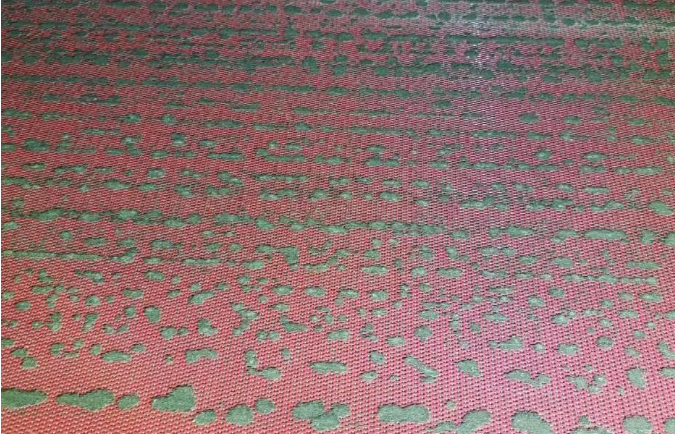

Oil stains on the dryer fabric

In addition, there are pollutants such as adhesives, inks, and chemical additive residues. These substances will form stubborn stains on the dryer mesh, further deteriorating the performance of the dryer mesh, increasing production costs and maintenance difficulties.

Adhesives and paper fiber pollution on the dryer mesh

Dryer net cleaning agent protects production cleanliness

What is dryer net cleaning agent?

Dryer fabric cleaning agent, also called dryer net isolation agent by some enterprises, is a chemical agent specially used for protecting the surface of dryer net in the papermaking drying department from pollution. Through special facilities, it can effectively form a protective layer on the surface of dryer net, isolate the pollution of pollutants to dryer net, and maintain the permeability and surface performance of dryer fabric.

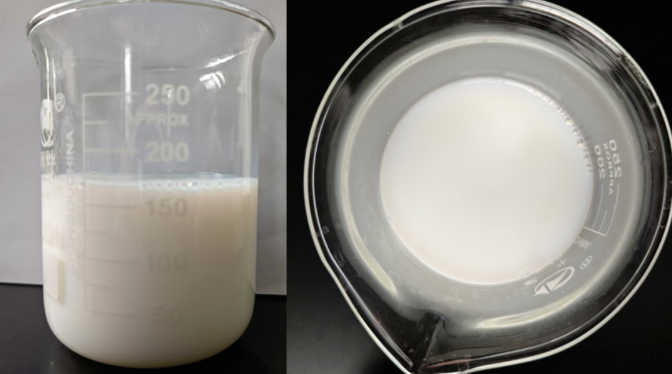

Dryer net cleaning agent is a milky white to light yellow liquid with a pH value of 5-7. It has a high flash point, strong heat resistance, oxidation resistance and large compression rate. It can be stable for a long time in the temperature range of (-) 10℃ to (+) 300℃, non-toxic and non-corrosive; moderate viscosity, will not cause oil spots on the dryer net surface, etc., completely solve the problem of adhesives deposited on the net surface in dryer papermaking, keep the net surface clean and have good air permeability.

Dryer screen cleaner appearance

Working principle of dryer fabric cleaning agent

Dryer net cleaning agent mainly realizes the protective cleaning function through chemical reaction and physical isolation. On the one hand, the active ingredients in the cleaning agent can react chemically with organic matter in the dirt to destroy its chemical structure. Reduce the viscosity of resins, adhesives, etc.; on the other hand, after the cleaning agent is sprayed on the dryer net, it can penetrate between the dirt and the dryer net, reduce the adhesion between the dirt and the dryer net, and then pass through the high-pressure flushing of the dryer net online cleaning equipment, and use the physical flushing force to remove the pollutants with the vacuum.

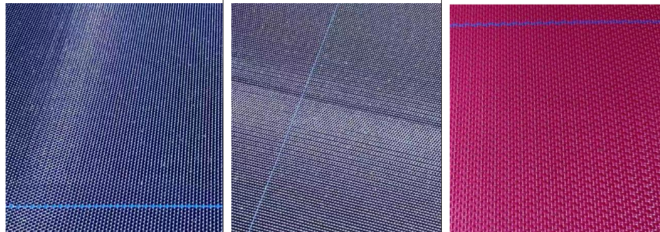

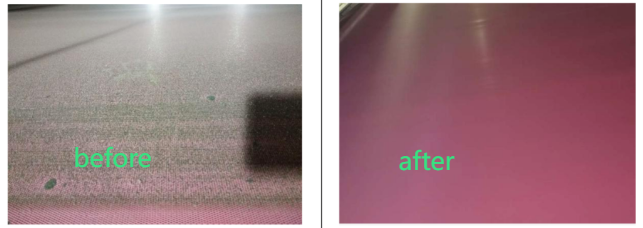

In modern high-speed paper machines, the effect is better when combined with the online high-pressure cleaning equipment for dryers. It is reported that many paper mills that have used dryer net cleaning agents no longer need to stop the machine for maintenance and cleaning of the dryer net, and the dryer net is basically kept as new from the time it is put on the machine to the time it is taken off the machine. (As shown in the figure, the actual photos of the 1-3 groups of dryers in the front drying department of a manufacturer after 3 months of use, the dryer net basically maintains the original color, and the surface is clean and transparent)

1st group 2nd group 3rd group

How to use dryer net cleaner?

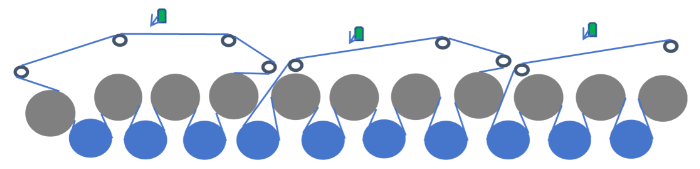

Dryer net cleaner is sprayed evenly on the continuously running dryer net through a special spray device mounted on the frame of the drying section of the paper machine (as shown in the figure below). During the spraying process, the nozzle moves horizontally at a uniform speed on the beam, and the cleaner is mixed with compressed air on the nozzle to produce atomization. The atomization of the nozzle must ensure that the sprayed particles are fine enough to ensure the effect.

Applicable scenarios of dryer screen cleaners

Whether it is a paper mill producing newsprint, writing paper, packaging paper or other types of paper, the use of dryer screen cleaners can maintain stable production and stable paper quality. Especially in packaging paper production lines that use recycled waste paper as raw materials, the use of dryer screen cleaners is even more important.

For example, many large-scale, highly modernized high-speed packaging paper production lines in China currently have 1-5 groups of pre-drying dryers and the first group of post-drying dryers as standard, which are used in conjunction with dryer screen online high-pressure cleaning equipment. There are also many medium and low-speed packaging paper production lines equipped with 1-3 groups of dryer screen cleaners and dryer screen online high-pressure cleaning equipment. (As shown in the figure below, a schematic diagram of the use of dryer screen cleaners in groups 1-3)

Advantages of using dry cloth cleaner

01Improve production efficiency

On the one hand, the dryer fabric after using dryer fabric cleaner can perform its function better. In the papermaking process, it helps the rapid evaporation of water, thereby increasing the drying speed of the paper, thus helping the paper machine achieve more stable operation. On the other hand, the dryer net after using the dryer net cleaner can be kept clean and transparent for a long time, without the need for cleaning or other processing during shutdown, saving labor and downtime for maintenance. At the same time, the clean dryer fabric effectively reduces obstacles to the operation of the paper machine, reduces paper breaks, improves the effective operation rate and increases output.

02Improve product quality

When the dryer web is kept clean, the quality of the products produced will also be significantly improved, avoiding contaminants such as paper bumps, holes, spots, and impurities caused by dryer web dirt.

03 Extend the service life of the dryer net

By continuously using dryer net cleaner to clean the dryer net, you can effectively reduce the erosion of the dryer net material by pollutants. Some chemical components in the pollutants may react chemically with the fibers of the dry fabric, causing the dry fabric to age and reduce its strength. Cleaning agents can remove these harmful substances in time and protect the fiber structure of the dryer, thereby extending the service life of the dryer. For papermaking enterprises, this means reducing the frequency of dryer fabric replacement, reducing equipment maintenance costs and production costs.

Environmental protection, cost and safety are equally important

01 Environmental protection

The importance of environmental protection to the papermaking industry. Therefore, the dry mesh cleaner fully considers environmental protection factors during the research and development process. Its main ingredients should be biodegradable. After use, these ingredients can be decomposed by microorganisms in the natural environment and will not cause long-term pollution to water bodies, soil and other environments.

At the same time, the use of harmful substances should be strictly controlled in the production process of dry mesh cleaners to ensure that the products meet international environmental standards. Using dry mesh cleaners, papermaking companies can actively fulfill their environmental protection responsibilities and reduce the impact on the environment while ensuring production cleanliness.

02 Safety

In terms of safety, the pH of dry mesh cleaners should be controlled within a safe range and will not cause serious irritation to the skin and respiratory tract of operators.

Under normal use conditions, as long as the operator wears appropriate protective equipment such as gloves, goggles, etc. as required, cleaning operations can be carried out safely.

In addition, dry mesh cleaners should not contain flammable and explosive ingredients to ensure the integrity of the product during storage and use, reducing the safety risks of papermaking companies.

03 Convenience

The use of dryer net cleaning agent should not increase the workload of paper mill staff, and can be added automatically online and continuously, and interlocked with the paper machine shutdown and paper break signals, and at the same time, it is convenient for daily equipment maintenance.

04 Accuracy of measurement

The addition of dryer net cleaning agent should use an accurate metering pump. The use of a metering pump that can conveniently and accurately control the flow is very important for cost control and safe use, to prevent excessive pollution of the environment and waste of costs and side effects that affect production operations and product quality.

Practical application cases

Case: Improvement of production efficiency in a paper mill

Before using dryer fabric cleaner, a paper mill in central China faced the problem of serious contamination of the dryer fabric in the dryer section. The air permeability of the dryer fabric decreases, resulting in uneven drying of the paper and a large number of defective products. Moreover, due to frequent problems with the dry network, frequent shutdowns are required for maintenance and replacement, which seriously affects production efficiency.

After using dryer fabric cleaner, the performance of the dryer fabric has been significantly improved. The paper dries more evenly, and the defective rate is reduced from the original 2.5% to less than 1.5%. At the same time, the service life of the dry net has been extended by nearly 40%, downtime has been reduced, and production efficiency has increased by 2%, bringing considerable economic benefits to the enterprise.

Conclusion

In today’s increasingly fierce competition in the paper industry, the optimization of every link may become the key for enterprises to stand out. With its powerful cleaning ability, environmentally friendly and safe characteristics, and convenient use, the papermaking dryer dryer fabric cleaner provides an ideal dryer fabric cleaning solution for papermaking enterprises. The application of dry fabric cleaner provides efficient, environmentally friendly and high-quality guarantee for papermaking production, injects new vitality into the development of the papermaking industry and creates more brilliant achievements.