In terms of the development of pulping technology, first of all, we should know some concepts about pulping, and paper-making processes.

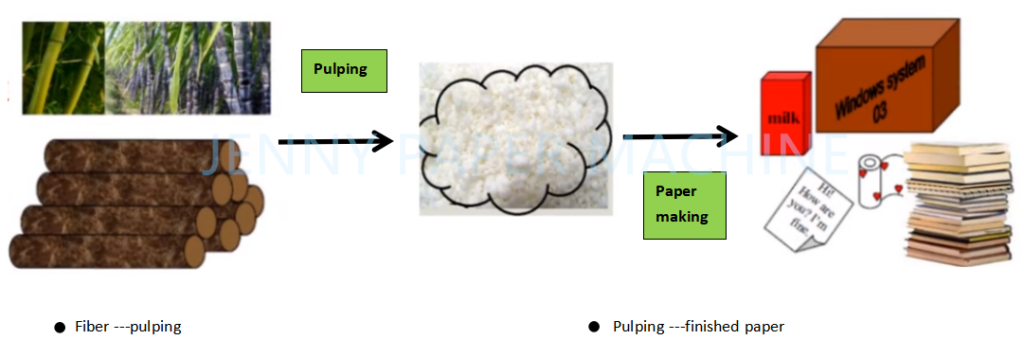

1.Pulping Process

Pulping is to transfer the plant fibers for paper-making into pulp, such as wood, bamboo, bagasse, etc. Paper-making is making all types of paper according to different requirements, such as newspaper (called newsprint in the papermaking industry), book paper, writing paper, high-grade printing paper, packing paper box, cardboard paper, etc. In the process of pulping, the raw material must be separated into a single fiber. The fiber bunches cannot be used for paper-making. So, pulping is the key point.

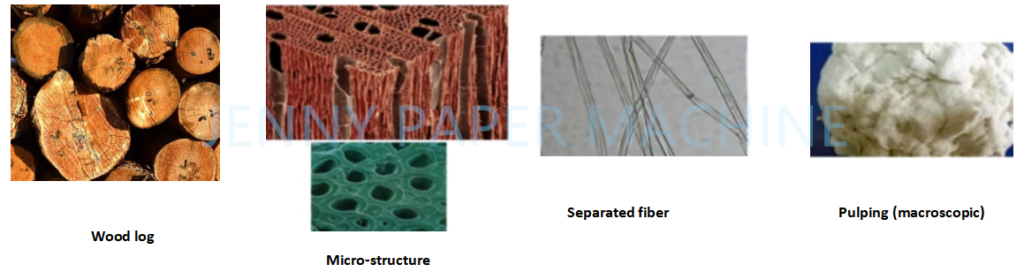

Next, let’s start from micro structure of plant to see how to pulp, taking wood as an example.

Example:

As we all know the wood log is flat and tight, then cut into small pieces of wood, and observing it through a micoscrop, we can see the structure of plant fiber, that is plant cells.

The plant fibers are closely bonded with lignin and hemicellulose, which can not be separated easily,so trees and bamboo can stand up straight. When being chemically or mechanically treated, fibers might be separated into dispersive ones, that is pulping.

Here are the key points we need to understand:

a.A single plant fiber is a single plant cell

b.Pulping is separated plant fibers

c.Paper making can be achieved only when the fibers are separated into single ones.

2.Pulping raw materials

There are many types of plant fibers, and not all trees can be used for paper-making.

The common trees for paper-making include: Pine,Eucalyptus, Birch, Poplar, Acacia mangium, etc. Some trees are too dense to prepare pulp. Others are not dense enough to prepare pulp.

Besides trees, grass fibers can also be used for pulping. Such as bamboo, bagasse, reed, straws, etc.

So can bast materials, such as mulberry bark, jute, sisal hemp, etc.

Every kind of raw material should be properly for pulping.

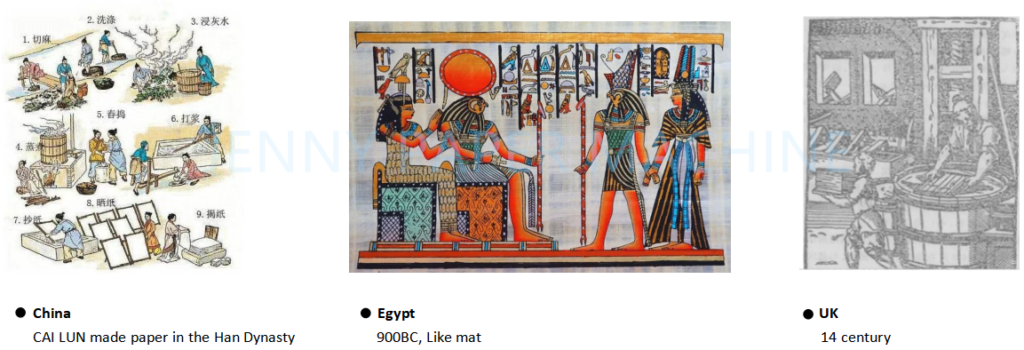

3.The development history of pulping

We all have heard about Cai Lun who made paper. It’s a great achievement of Chinese ancient paper-making technology. Cai Lun summarized previous experience to expand the sources of raw material.

Firstly bark for paper-making, which is much more abundant than bast fiber plants. It can help to greatly improve output and to improve papermaking technology. Then paper quality is greatly enhanced, so it’s gradually accepted by the public. The paper also proved appeared in ancient Egypt in BC 900. However, it was not the real paper, but a fabric-like mat. Therefore, there is no scientific evidence showing that it’s their ancestors who invented papermaking technology. For Western countries, it was pretty late when papermaking technology was invented. The paper didn’t appear in the UK until the 14 century.

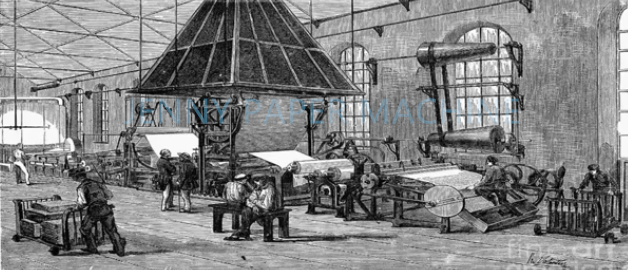

However, modern pulping and papermaking technologies originated in Western countries.

In 1798, the French adopted a seamless net to make papermaking machines. It was put into service in 1804.

This picture shows the papermaking machine at that time:

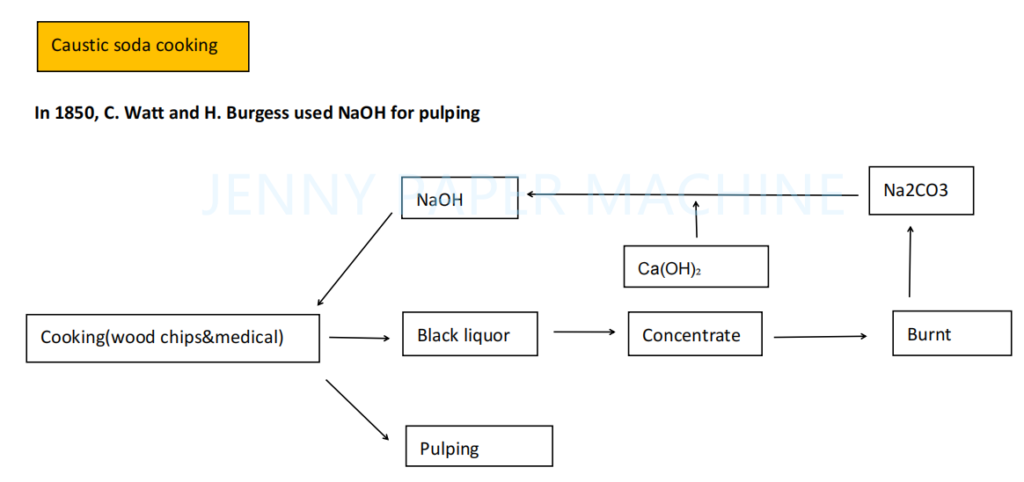

In terms of pulping, the industrial pulping technology is to cook with caustic soda.

The reason why this technology can be industrialized is because the chemical medicines are recycled.-Plant fiber material, such as wood pieces generates alkaline black liquor by cooking in NaOH liquid, while pulping is prepared. The black liquor turns into NaCO3 after being concentrated and burnt. And then the Na2CO3 turns into NaOH after causticization, which can be used as cooking liquid again without any waste discharge. Though our ancient papermaking technology can be used for pulping, it was not possible to achieve large-scale production due to the direct waste discharge that may cause environmental pollution. So, the large-scale production cannot be achieved.

Sulfite pulping

- In 1866, Benjamin Tilghman, from American, invented sulfite pulping technology;

- In 1874, Ekman adopted this technology in the industrial production of Sweden and it was used until the 1930s;

- In 1879, Dahl had the same idea and patented it 15 years later;

- Tomlinson’s breakthrough came in 1930;

- After 1960, the development was rapid, and more than 90% of pulping is currently made by the sulfate process.

Though people didn’t know about the principle, Cai Lun’s papermaking technology is still consistent with the modern one, so it can be globally acknowledged. Actually, it’s not the sulfate radical that works in the process of sulfite pulping, but sulfide. Because Na2SO4 is added to Na supplement in the process of burning, it was believed that sulfate radical worked at that time, and then it was named sulfite pulping technology.

4.Three features of modern pulping enterprises for papermaking

- Low profit per unit product and long payback period(It’s an industry of scale economics effect.)

- High-tech is required(It’s a technology and talent-intensive industry calling for the cultivation of technical personnel)

- Large investment(It’s a capital-intensive industry, 100–150 million RMB need to be invested for the ten thousand tons of output. For a pulping plant with annual output of million tons over 10 billion RMB are required. )