1.About raw matarials

Q:We know that paper is made out of really basically two different types of fibers: mechanical fibers that are mechanically pulps and chemical fibers that have been chemically pulped and bleached. Is this important to your process?

A:The brightness is that we have to achieve work. We’re typically looking for mostly chemical pulp so as the waste paper comes in our material handlers grade at the dock, and one of the tests we do is a spring floor loosen all to help look for and show us, you know, how much mechanical fiber might be in the waste paper.

We have an inspection worker. so floor glue señal is somewhat corrosive so he has his proper PPE on for you know for spraying this product but he’s looking for a color change. If that had been mechanical pulp it would have turned red and possibly even a deep purple if it had enough mechanical in it. As it is, we’re, what we’re looking at right now we know for sure that this is a this is a good chemical pulp paper. This particular paper is a pre-consumer grade but you know to us what’s also important is we’re, we’re saving this paper from having to go to the landfill by being able to use this. It is a small percentage but it is a pre-consumer grade. If you will notice though all the the foil-looking material on it as well as there will be some poly up in this process by our special puller that we have our drum pulper easily removes these contaminants whereas traditional batch pulping. This would be too much trash for the D- pulpers.

Q:Can you tell us a little bit about where you get your paper from and kind of the purchases that you make to feed your system?

A:You know our waste paper or recoverable paper can come from anywhere east of the Mississippi. We extend up into Canada a huge portion up into the Northeast you know the major cities Philadelphia, New York City. You know out of New Jersey down the east coast into the southeast. So, comes from everywhere.

Q:What kind of paper do you purchase?

A:The biggest majority of what we’re purchasing is sorted office paper also known as a sort of office waste, basically, it can be any paper that might come out of your office drawers or a file cabinet that gets dumped. You know, it comes in both shredded and also you know whole loose paper.

Q:So these storehouses hold a lot of paper about how long can your mill run on what you have in your warehouse.

A:If our warehouses were completely full, we’re probably good for only about four or five days. This is a very large mill.

Q:This mill is pretty special, it accepts very difficult-to-recycle paper products. can you um tell me what those are?

A:Some of these papers are things like orange juice boxes, milk cartons, and accept packaging. These are all containers or papers that were treated to hold liquids. So, therefore, you know by just going in our process to begin with the difficult tore-pulp and re-slush. So with the correct chemistry enough time and energy going into the fibers, we can defiber those and reuse those as beneficial, beneficial streams as well.

2.About Water Resource

Q.For your process, we know you need water. How do you get the water and how do you treat it before it comes into your process?

A:We pull water straight in from the surface of the Monongahela River. The Monongahela River is formed right here in Fairmont. Becomes one of only a couple of rivers in the world that flows north and is navigable. But we take that surface water and it’s too dirty for our process, so we have to clean it so we’re standing on top of our the river water clarifier. We add chemistry, we add both a coagulant and a flocculent to bring the particulates together, and then we settle that out to get to much cleaner water to use, and then that water passes through a sand filter media system there again. It’s just you know, it’s a separation if something is too big to go through that fine sand media, it’s rejected. You know and then typically what we see there is mud, and then our final product of the freshwater then is a very clean water like less than one NTU so looks like drinking water, but it’s not potable. We don’t treat it for that, but it’s very clean water for our process.

3.About Process Flow Chart

Q:Can you want to introduce us to the process before pulping?

A:What happens to our pulp or operator here. We’ll take a bale of waste paper and place it on the conveyor. It’s the whole bale. What we have here is a D wiring device so it automatically takes the front of the wire from the bale that way it keeps our operators safer. You know they’re not cutting wires or being exposed to that hazard, and then the wire wolf will then drop the paper onto the floor, and shove it into the pit, and from there the conveyors are all level controls and everything. But we calibrated that to know how much weight, we’re going to put into this pulper and then what’s inside this pulper. It’s a high-consistency copper. We do use water and a little bit of sodium hydroxide to help break down those wet strength properties. It uses a helical rotor inside and again it’s a batch pulper, so it’s going to be in here for, you know. Somewhere around an hour which is you know that’s all controllable, but probably somewhere around an hour it’s going to be mixing and breaking down on fibers.

3.1Pulping

Q:So at the end of the pulping after you would be refiber as much as you need to. It’s a high-consistency pulp, so it’s pretty hard to pump. How do you get it out of the pulper?

A:So at the end of its mixing cycle then we add more water to the pulper, bring that up to a level and then the pulper is dumped at a much lower consistency that’s you know, much easier for the pumps to pump, and from there then it’s stored in our access tank, and then it’s metered into the process from the point.

Q:So there what do we have behind us right now?

A:What we have behind it’s not right now, which is a conveyor that’s feeding the pulpers, so we’ve taken our waste paper. We’ve removed the wires automatically, and the conveyors are going up this whole time to go up to the pulper. We are measuring it with a nuclear device that basically is looking at the density of the paper, and from that device, we’ve calibrated that based upon whatever density it is. We convert that into a weight or how many tons they want it to be feed. So the conveyor will speed up and slow down to meet that, set point that the operator upstairs, asks for the amount of paper coming into the pulp.

Q:So for your pulper to operate correctly, you have to have a certain number of tons per hour. Let’s say fed in, exam that censoring device is going to allow you to measure that, and either increase or decrease the speed of your conveyor.

A:Along with the DCS, then we’ll calculate how much water, you know to add with this paper so we have the proper consistency when we’re repulping.

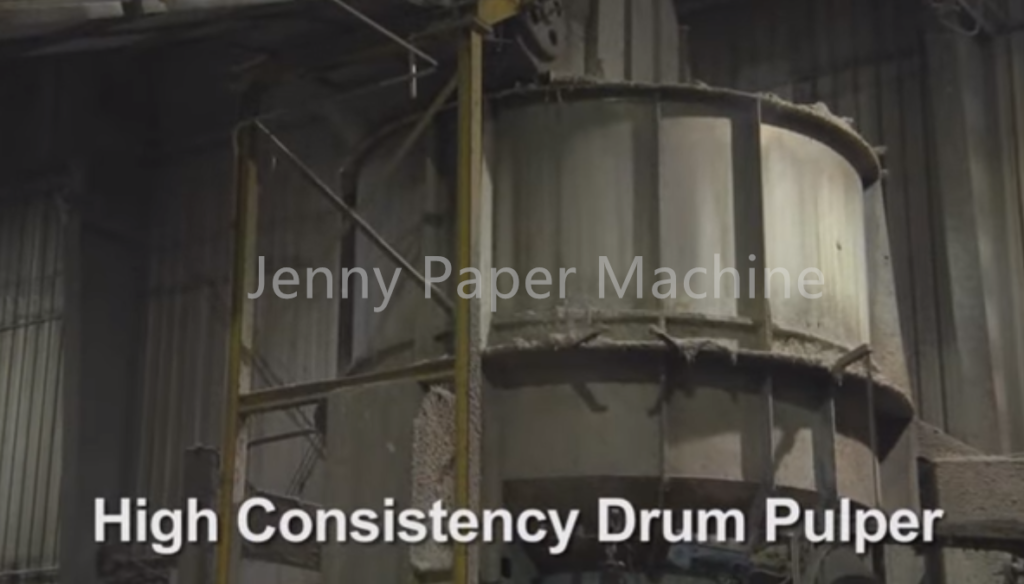

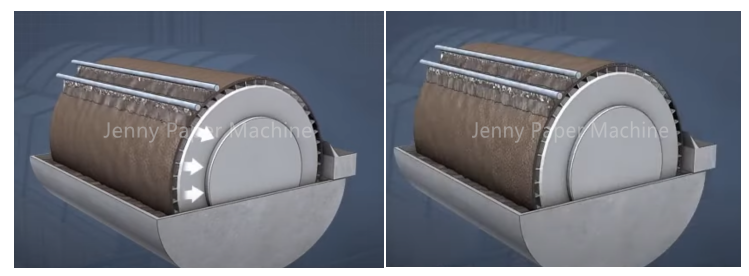

Q:We’re in front of your drum holder now this is a conventional pulper for most of your material. Can you walk us through how that drum pulper works?

A:What’s happening two conveyors that we saw earlier are confluency together, you know based upon what the DCS is calling for weight. The paper is been dumped into an open end of the drum hopper along with water. Our recipe calls for a certain consistency. It is high consistency, pulping that we do and at that point then the paper and there are baffles and everything inside the drum the paper in the water together is lifted at about like a 10 or 11 o’clock position, and then it falls and that constant as the drum is rotating and the falling that paper and water together reslushes or fibers the waste paper. It’s very gentle compared to conventional batch pulper, this way we try to keep our contaminants that come in you know our wood, our pop cans, you know banana peels whatever comes in. We try to keep them as largest as we possibly can with this general pulping. At the end of the pulper, we have a screening section where the highly consistent pulp is now hit with newer water that helps to wash the paper fibers off the contaminants. The paper fibers fall through those perforations and come accepts and then our rejects come out and those nice large pieces at the very end of the drum.

3.2.Cleaning stage

Q:After the pulp comes out of the pulper, we go straight through the high-density cleaner ,high density cleaners works.

A:Yeah, what we have is that high-density cleaners are going to go after separating materials by weight or intensity. So what’s happening is that the material is fed into the cleaners to set up in a rotating motion and by consistently go forward. All the heavy material falls and goes out. It’s dropping, and then by that is up down in the grip pot, which under timers dumps the rejects and by a differential pressure the stuff in the center, which is the access. There’s a vortex in the top that the pulp comes out the top. And in fact, steps of that away by differential pressure.

Q:After the pulp is cleaned with the high density cleaners to remove the big staples and glass and things like that. It comes to the screening operations. Can you tell us a little bit about the screening operations?

A:what we have in screening is now we’re going to create a barrier. In other words, unless the contaminant is small enough to be able to pass through these slots, then it’s going to become a reject. So what barrier screening and we use pressure screens. What that’s doing is going after contaminants by shape and size. We use slotted screening in both our course screens and our refining screening, and if you look and see again you know, unless something is small enough to get through those slots. It’s going to become a rejection. It cannot pass through it. This is a barrier.

Q:so the concept is that the fibers go through the slots, and the large contaminants are blocked by the slots, and they go out a reject sport exactly. Okay, you have coarse screens followed by fine screens is that correct? Can you tell me what the difference is between coarse screening and fine screening?

A:Coarse Screening is going after rubber bands and plastics and stuff like that fine screening is again probably like 25% of the width of what a coarse screen slot is, and the main contaminant were going after at that point and it’s stickies in the in our industry, you know, coming from bindings post-it notes self-adhesives. But the stickies are what we’re primarily looking at in our, in the find screening section. That’s the heart of the removal of stickies in the mill.

A: Pls tell us about the low density cleaners

Q:These are in our state’s primary cleaners. We have 96 of these cleaners and again it’s doing the same action of identity, so you know a lot of centripetal actions what’s special about our primaries is inside of each of these bodies are three small cleaners, and then as we come down the middle also in my primary, my secondaries. We’re also and re-energizing water to help thin out the reject but it’s also re-energizing that centripetal force to keep the fibers in the stander and the rejects out the end. So I have my primaries which have a higher reject rate again I want to get pulled in and get it out, get passes on it is a process, and then over here in my secondary stage, I began reclaiming some of those fibers so the reject ratio not as high as what we have in the primaries behind, so the primaries and secondaries are the same model type of up cleaner.

This is our tertiary stage before cleaning. Now this type of cleaner it’s only one cleaner so it’s a little bit bigger on the inside. The same thing, though we’re still subscribed to action the reject rate from this one is again lower than we’ve had some secondary a little bit special about our tertiary the lower reset tip. Here is transparent so we can see whether or not we’re having a slugging action, and then finally we have our quaternary stage. A quaternary stage is our last stage so the exact same is the tertiary – – the transparent tip, but this tip is because the rejects are so concentrated, and dirty. It’s a porcelain material down there because otherwise, the wear rate would be so high that we never be able to keep up with replacing the lower reject density cleaner so again there are four slim materials and then after our final stage rejection there leave the mill and the exit the excess from each

one of these goes back beating the sub school stays in front so my access quaternary goes back to the tertiary, tertiary go back to secondary , secondary go back to primary and if it’s good enough becomes access.

3.3 Pulping Washing

Q: So what is the next?

A:After Four cleaner access, we’re coming near the end of our first stage by washer.We’re going to do that now with by washing the pulp so the access by four cleaners comes to a pair of gravity Decker drums and the pulp is both gravity and it is underneath these drums has to go through a rotating drum, and this action of removing the water is a washing action, so small neat particulate and fillers and everything go with the water and you have the pulp then being accepted into a stock shed for our next dewatering session.

Q:After the gravity Decker what happens next?

A:Next the pulp is, then pumped up to our twins are impressive somewhere around the constancy of 4% probably is at the head box has to go subsequent the gravity draining song, and then a wedge song, you know, with gradual decrease pressure from you to fabrics then we go through a nip section of Preston section, so bonding our final answer again. I know this article 50 as you see is very heavy, it’s probably somewhere between 35 and 40 percent fiber, no water left in it. And it’s been preparing the pulp man port for the kneading section that’s next.

Q:Can you explain to us what the neater does and why use it?

A:The function of the neater is to take the pulp and as it sounds. It’s a whole lot. It’s a fiber-to-fiber actions so so the job, what it’s trying to do is that fiber is rubbing it into the pulp, is rubbing against itself. It’s to detach ink particles from the pulp paper fibers and then of course follow the leaders right away, then is going to be our first stage flotation. We’re going to remove the ink from the slurry.

The neither actually rubs those ink particles off the fibers and then that prepares it so that the flow shaped a shinji inking process is more efficient.

Q:What are the conditions in the neither?

A:A lot of horsepower just the action itself adds heat to the fiber so it’s dispersing, but we have to take care not to add too much power. Because we can also create fines.