Introduction

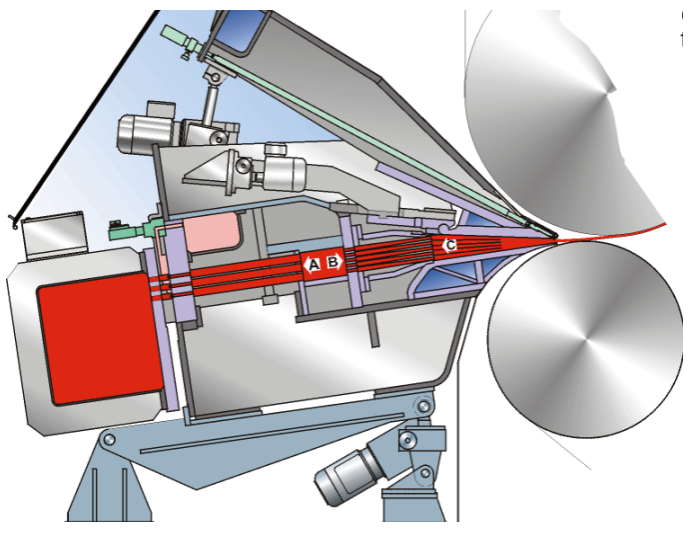

The headbox is the heart of the paper machine and plays a vital role in papermaking. The quality of the headbox will directly affect the operating efficiency of the entire paper machine and the operation of the entire paper mill. Only a healthy and excellent headbox can produce excellent and qualified paper. The normal operation of the headbox related mechanisms is very important to meet production needs. If the headbox fails to operate, it will seriously affect production and may directly lead to shutdown.

This article aims to share the most popular headbox action mechanisms in the world. As for the troubleshooting methods of various headbox action mechanisms, they will be discussed separately later.

The action of the headbox generally includes vertical opening action and horizontal action. The vertical action is to control the amount of sizing, and the horizontal action is to adjust the screen point.

Most of the clamped headboxes are equipped with an inclination action, and the inclination adjustment replaces the horizontal action to adjust the screen point position. Of course, it also includes the action of the fine-tuning mechanism and the pulp inlet cone, but it is not within the scope of this article.

Vertical movement of the headbox

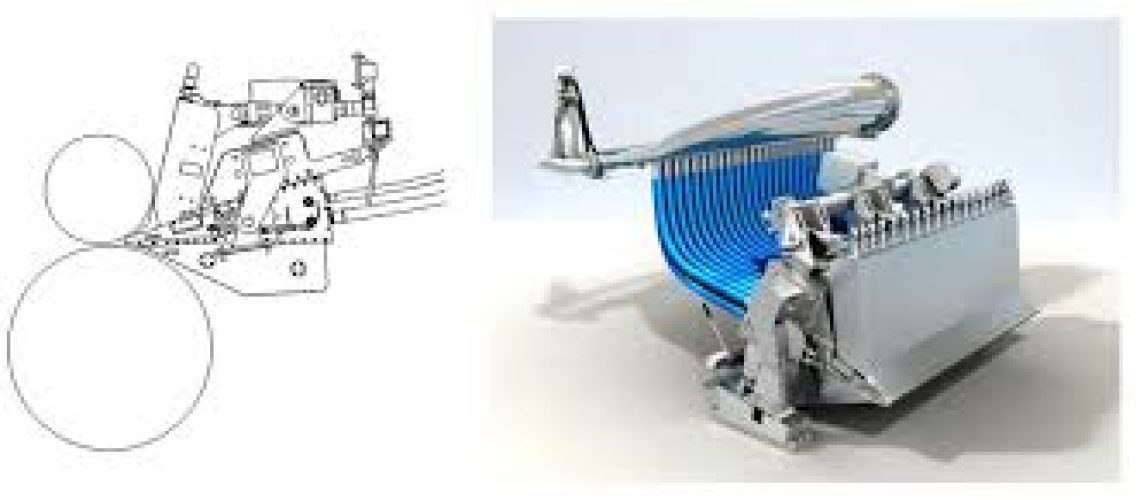

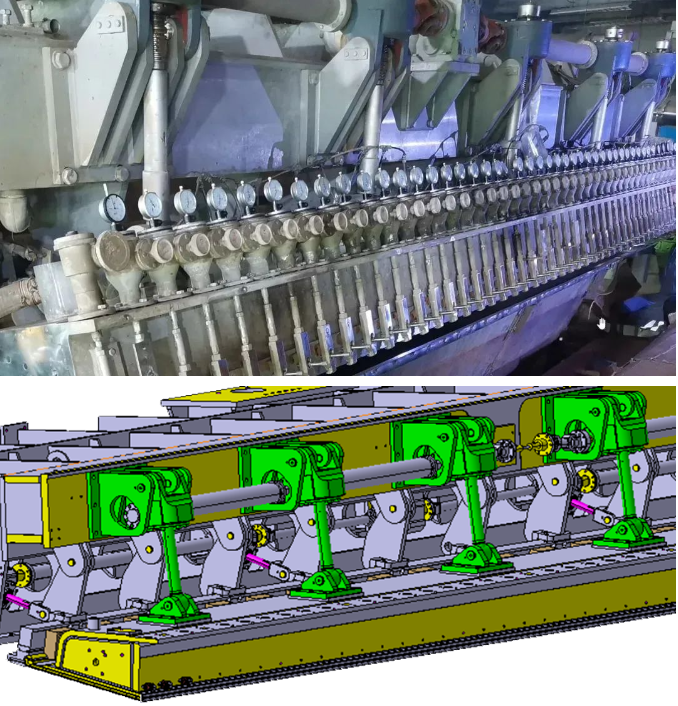

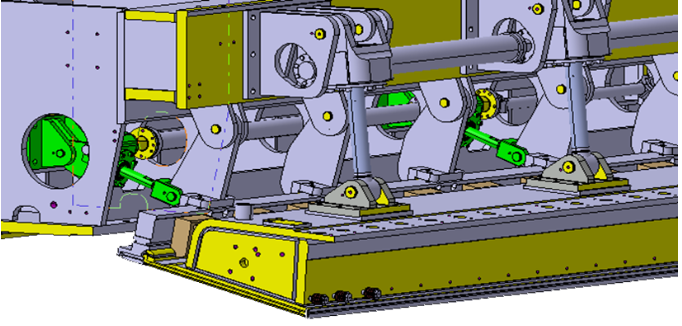

The vertical movement of the headbox is to adjust the lip opening of the headbox. The normal operation of this mechanism is crucial to the headbox. Most of them are of similar design, that is, multiple worm gear boxes installed on the frame directly act on the upper lip plate beam, and the upper lip plate beam has a rotating joint mechanism. The motor reducer is connected to the synchronous shaft to drive the worm gear box to act on the upper lip plate beam. The upper lip plate beam has a small rotating joint stuck on the frame. The worm gear box directly drives the upper lip plate beam up and down. (As shown in the figure below)

At present, the most popular vertical action headboxes are mostly of this design. Some vertical action worm gear boxes are on the front side, and some are on the back side, but the principles are basically the same. Because vertical actions are frequently operated, failures are rarely encountered in actual applications. On the contrary, horizontal mechanisms with fewer actions are more prone to problems.

Analysis

The following is a typical headbox with a vertical action worm gearbox on the front side. The most common problem is the failure of the intermediate action motor reducer, and the wear or damage of the worm gearbox. The motor can be directly replaced if the motor fails. After the worm gearbox is replaced, the vertical direction of the upper beam needs to be recalibrated. Make sure that the parallelism of the upper beam and the lower lip plate at this position does not change too much before and after the worm gearbox is replaced.

Some paper mills will encounter faults caused by abnormal wear of the rotating joint. If the wear gap of the rotating joint is too large, the vertical action will be out of sync, the quantitative fluctuation of the banner will be large, and the horizontal position may also be deviated. If the joint mechanism is damaged, it is very troublesome to handle.

Horizontal movement of the headbox

Regarding horizontal movement, the most popular flow box structures are mainly the following three types:

- The first is the upper lip plate direct-acting type, which means that the horizontal action worm gear box directly acts on the upper lip plate beam to move forward and backward.

- The second is the large and small joint shaft type, which means that there are two large and small shafts assembled together. The small shaft is vertically moving, and the large shaft realizes the horizontal movement.

- The third is the lower lip plate direct-acting type, which means that the horizontal action worm gear box directly acts on the lower lip plate to move forward and backward.

The three forms have different structures, and the designs of different manufacturers are also very different. Even the same supplier may have several designs.

Upper lip plate direct-acting type

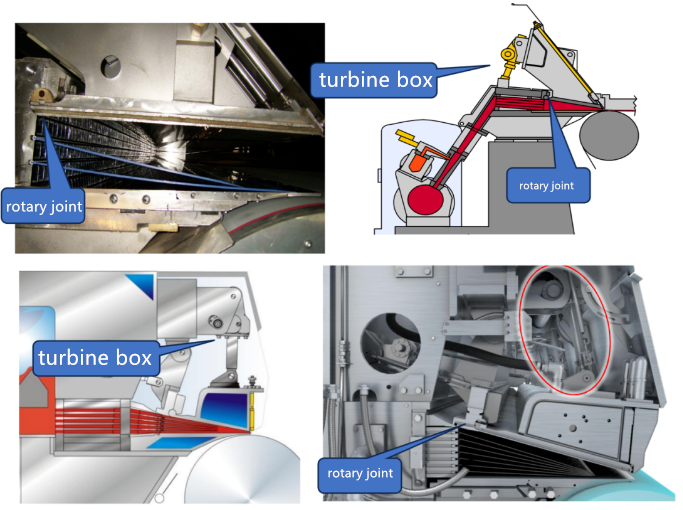

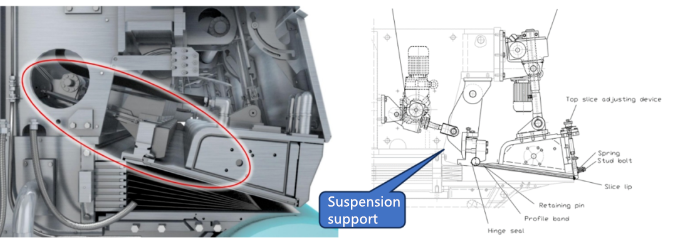

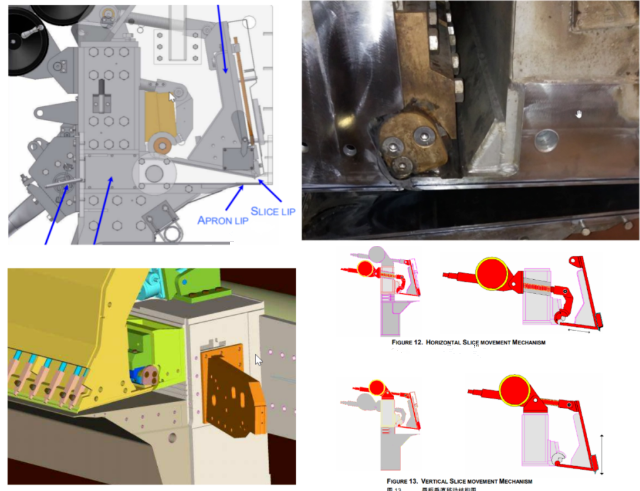

The upper lip plate direct-acting type means that the horizontal action worm gear box directly drives the upper lip plate beam to move forward and backward. The horizontal direction worm gear box base is fixed on the beam, the worm is connected to the upper lip plate beam, the upper lip plate beam has a fixed suspension mechanism to suspend the upper beam, the motor reducer is connected to the synchronous shaft, and the worm gear box drives the upper lip plate beam to move forward and backward, similar to the following:

The upper lip direct-acting type is the most common horizontal motion control method, and most of the domestic suppliers in China currently imitate this design. This design of horizontal motion places a series of components above the weir area of the headbox, and the upper part of the headbox has a complex structure.

Some horizontal action worm gear boxes are hidden inside or on the back of the upper beam. The motor reducer of the horizontal action is connected to all worm gear boxes by a synchronous shaft. Several horizontal action worm gear boxes drive the upper beam to move forward and backward. The upper beam is basically suspended on the frame by a mechanical support to slide forward and backward. The upper beam must never slide directly on the turbulence generator. The upper lip plate beam must have a fixed support. The sliding clearance of the sliding surface must be appropriate so that it will not get stuck or wear the sliding surface after a few years of operation. The sliding surface is equipped with a seal to ensure no leakage. The horizontal movement of the slurry box requires a very scientific design to have a long service life.

There are also various designs for direct-acting slurry boxes. Some designs are suspension arms, some are based on sliding copper plates for sliding, and some are upper beams sliding on multiple slide bars. When the direct-acting slurry box moves vertically, it will also slightly affect the horizontal position, and the horizontal position movement will also slightly affect the vertical opening.

Large and small joint shaft type

At present, most well-known headbox manufacturers in the world basically use this design. The vertical movement is that the worm gear box drives the upper lip plate beam to rotate around the small shaft joint, and the horizontal movement is that another set of worm gear boxes drives the large diameter joint to rotate, and the large joint drives the lip plate to move forward and backward (non-linear movement).

Because the frame mechanism of the mechanical attachment of the horizontal movement determines that the lip area is a non-standard forward and backward movement, this double joint design will have a situation: when operating the horizontal movement, it will directly affect the vertical opening, and when the vertical movement is also affected, the horizontal position will also be affected. If there is a worm gear box failure, the action is delayed, and there is a deviation in the single-side screen point, it will also directly affect the lip opening difference by about 30%. (If the worm gear box on the operating side lags in action, and there is a 1mm deviation in the horizontal position between the operating side and the transmission side, there will be a deviation of about 0.3mm in the vertical direction).

Lower lip plate direct action type

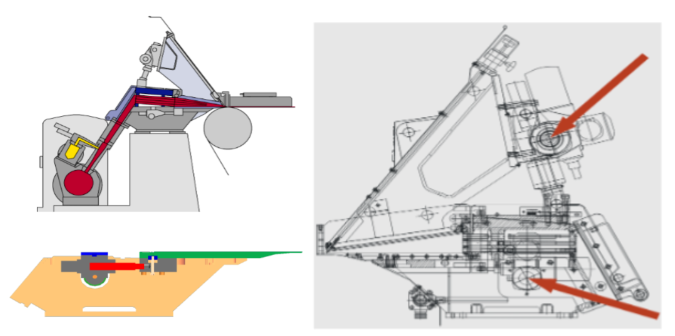

Some headboxes use a worm gear box to directly act on the lower lip plate for horizontal adjustment, and the mesh points are controlled by the movement of the lower lip plate.

The first two action mechanisms will affect each other, that is, the vertical action will slightly affect the horizontal position, and the horizontal action will also interfere with the vertical opening. Only the third design has the advantage that when the lower lip plate moves horizontally, it will not have any effect on the vertical direction, that is, the lip opening.

Headbox inclination control

Headboxes with inclination control are generally used in web-grip paper machines. The inclination action is used to adjust the screen points or to facilitate web changes. There are safety limits on both the upper and lower positions of the inclination control to prevent the headbox from moving too high or too low and hitting the two rollers at the exit.

The inclination motion is simpler and more convenient to maintain than the horizontal motion. The headboxes of the mesh paper machines, toilet paper machines and some fourdrinier machines use the inclination motion to control the headbox instead of the horizontal motion.

Summary

No matter which action of the headbox, multiple worm gear boxes simultaneously push the upper beam or lower beam to move synchronously. If a worm gear box is not maintained in time, the worm or internal copper sleeve is worn or the internal bearing clearance becomes larger, the action will obviously lag behind the worm gear boxes in other positions. If there is a problem in the horizontal direction, it will directly lead to the position deviation and uneven dots at this position; the vertical direction is not synchronized or the action is delayed, which will directly affect the banner quantity. In the case of obvious impact, it is necessary to replace the worm gear box, or adjust the worm gear box gap, and re-calibrate the horizontal position of the upper lip beam.

The performance accuracy requirements of the headbox action mechanism are very high, especially for high-speed and paper machines with very high requirements. Generally, the synchronization lag deviation of each worm gear box in the vertical action is recommended not to exceed 0.1mm. The vertical and horizontal parallelism deviation of the new headbox assembly shall not exceed 0.3mm. When assembling a new headbox, the beam will be calibrated and synchronized in both directions. It is also recommended to test and calibrate the headbox regularly after the headbox has been running for several years.

The headbox is out of sync or stuck. Different headboxes have different problems and require different solutions. Whether it is simply replacing a worm gear box or the whole movement is stuck, the relative position of the upper and lower lips needs to be recalibrated. If necessary, it may be necessary to remove the entire upper beam and replace the rotating and sliding mechanism. Solving such problems requires professional skills and a lot of work. It is recommended to seek professional suppliers for such maintenance.