Bleaching of pulp is a very important process in the making of right kind of Pulp

Purpose and Principle

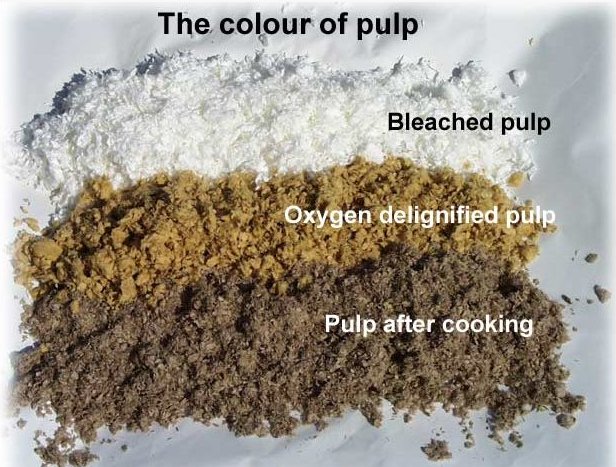

The purpose of chemical pulping is to remove as much lignin as possible in order to improve the flexibility of the fiber and the strength of the fiber-to-fiber bond. Unfortunately, pulping alone cannot remove all lignin, and chemical treatment during the pulping process will reduce the brightness of the pulp. The brightness of kraft pulp (alkaline conditions) decreases more seriously than that of sulfite pulp (acidic conditions). In other words, the brightness loss of acid sulfite pulp is relatively small and it is easier to bleach (Papermaking from Scratch: Exploring the Process of Wood to Pulp (Part 2)).

Some pulps do not need to be bleached and can be used directly, such as when the brown color of kraft pulp does not affect the performance of paper products. Paper produced from unbleached kraft pulp (Kraft Pulp) is called “Kraft Paper” and is mainly used for packaging. The main characteristic of this paper is its good strength.

Usually, chemical treatment during the bleaching process tends to weaken the strength of the fiber while whitening the pulp.

The purpose of bleaching is mainly to improve the brightness of pulp (Brightness, in the Chinese papermaking industry, whiteness is used as a synonym for brightness. In order to conform to everyone’s reading habits, it is uniformly referred to as whiteness in the following text) so that pulp can be used in applications that require whiteness (for example, paper that needs to be printed).

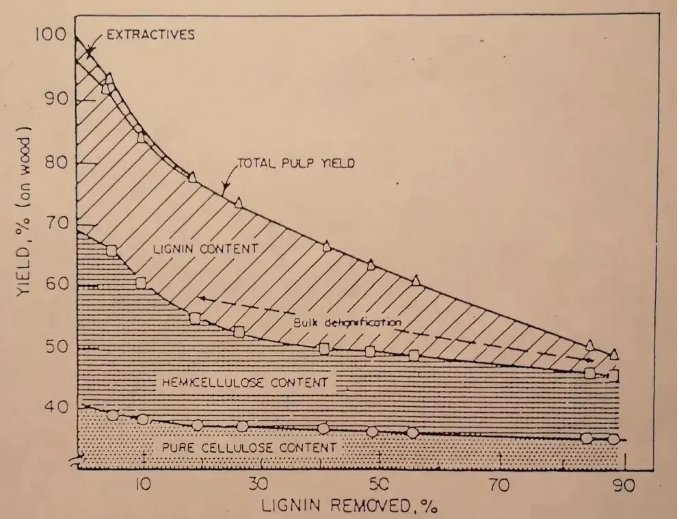

Simply put, bleaching is the process of removing the residual lignin (lignin accounts for about 3-5% of the pulp composition before bleaching) and other colored impurities as much as possible after pulping. The following figure is a curve showing the yield change of the main components at different delignification stages in the softwood kraft pulping process:

Change curves of main components in different delignification stages during pine kraft pulping

The content of residual lignin in pulp is usually measured by the Kappa number (Kappa). The Kappa number multiplied by 0.15 is the percentage (%) of residual lignin in the pulp. For example, pulp with a Kappa number of 20 contains 3% lignin.

The Kappa number of pulp reflects the degree of bleaching. In order to achieve the required whiteness, bleaching treatment is required.

The difficulty of bleaching is that the residual lignin in the fiber after pulping is highly condensed and difficult to dissolve. Therefore, many steps are required in the bleaching process to remove it.

Pulp bleaching improves paper quality in two ways:

a.on the one hand, residual lignin is brown under light, and bleaching can improve the whiteness of pulp and improve the stability of pulp whiteness;

b.on the other hand, the bleaching process can effectively reduce impurities and dust such as fiber bundles, thereby improving the cleanliness of pulp.

Bamboo Pulp

Oxidation and extraction alternative

Simply put, bleaching is a multi-step process in which oxidation and extraction alternate and repeat.

Bleaching agents (such as chlorine, chlorine dioxide, oxygen, ozone, etc.) have oxidation potential, accept electrons from lignin, and degrade lignin; oxidation produces new functional groups (such as carboxyl groups) to promote the dissolution of lignin.

Alkaline Extraction (called E in the bleaching section, or alkali treatment) can remove the substances produced by the reaction and the dissolved lignin.

The main oxidants used in pulp bleaching are:

- Chlorine: Cl2 (the bleaching section is called C). Chlorine is almost no longer used because of the formation of dioxins (which are very harmful to human health) during the chlorine bleaching process;

- Chlorine dioxide: ClO2 (the bleaching section is called D);

- Oxygen: O2 (the bleaching section is called O);

- Hydrogen peroxide: H2O2 (the bleaching section is called P);

- Ozone: O3 (the bleaching section is called Z).

Chemicals used for lignin extraction: Alkali (NaOH) is called E in the bleaching sequence, such as Eo, Ep, Eop, etc.

Pulp types and performance indicators

Depending on the bleaching sequence used in the production process, pulp can be divided into different types:

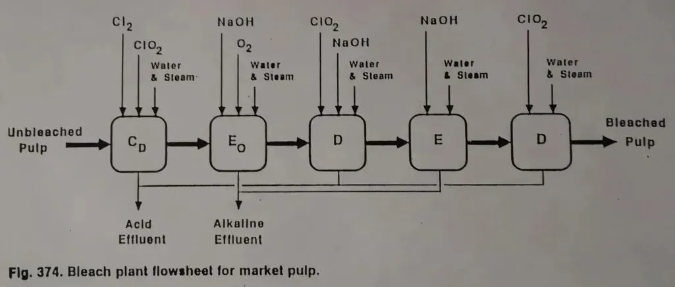

Traditional pulp is bleached using chlorine, but these pulps are disappearing (due to the production of dioxins during the production process). I don’t know if there are still some pulp mills using Cl2 bleaching in reality. According to different bleaching processes, there are CEDED pulp and C/DEoDED pulp (as shown in the figure below, the bleaching production process of traditional commercial pulp);

The production process of conventional pulp using chlorine bleaching

- ECF pulp (Elemental Chlorine Free): These pulps are not bleached with chlorine (Cl2), such as pulps with DEDED bleaching process;

- TCF pulp (Totally Chlorine Free): Pulps produced without using any chlorine-containing compounds, such as pulps with OEOP or OZEP bleaching process.

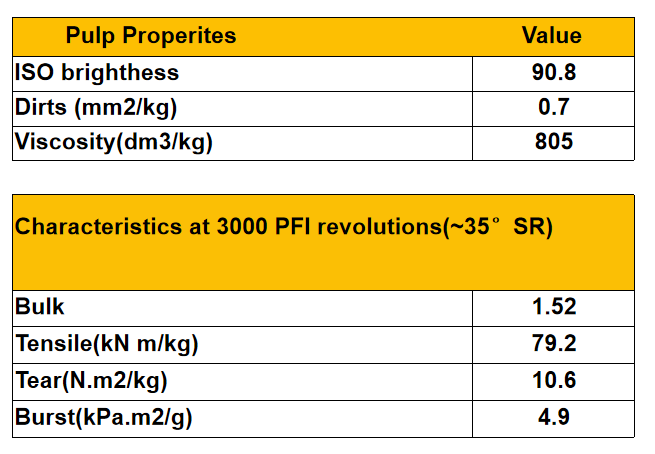

What basic performance indicators of bleached pulp should we pay attention to?

When purchasing commercial pulp, paper mills usually obtain the following performance indicator information about pulp from pulp suppliers:

- ISO brightness: reflectivity at a wavelength of 457nm (in the previous two articles, we have introduced the knowledge related to optical performance);

- Dirts: the total surface area of opaque particles under transmitted light, in mm²/kg;

- Viscosity: measured in dissolved cellulose, in dm3/Kg. Generally, the higher the pulp viscosity value, the better the pulp strength;.

- Moisture content: the percentage of moisture in pulp;

- Mechanical properties after refining: usually the pulp is refined by PFI in the laboratory (3000 revolutions, or the beating degree is controlled at ~35oSR), and then the pulp is made into hand sheets to test the physical indicators of the hand sheets.

Below is an example of an indicator for Brazilian eucalyptus pulp.

Brazilian Eucalyptus Pulp Index

Impact of pulp production on the environment

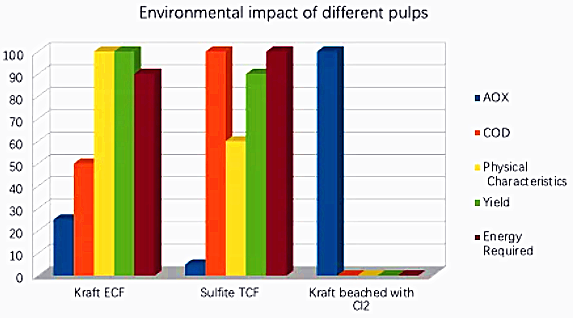

The impact of different pulp production on the environment varies, as shown in the figure below. The Y axis in the figure is a comparison of relative degrees, with 100 representing any given maximum value.

The impact of different pulps on the environment

- Adsorbable Organic Halogen (AOX): Sulfate pulp bleached with chlorine (Cl2) will produce a large amount of harmful AOX, which is why chlorine bleaching has been basically eliminated;

- Chemical Oxygen Demand (COD): The COD of sulfate ECF pulp is half of that of sulfite TCF pulp;

- Pulp yield: The yield of sulfate ECF pulp is higher than that of sulfite TCF pulp;

- Pulp strength: The strength of sulfate ECF pulp is better than that of sulfite TCF pulp (the strength of sulfite TCF pulp is about 40% lower);

- Energy consumption: The energy consumption required to produce sulfate ECF pulp is 10% less than that required to produce sulfite TCF pulp.

Conclusion

In the last century, the proportion of commercial pulp in the market was very small (about 10%), and most of the papermaking companies in Europe and the United States were integrated plants, that is, the factories produced their own pulp and were self-sufficient in internal paper production.

However, with the rapid development of China’s papermaking industry in the past two decades, China has built large paper mills, but due to the limitation of raw materials, pulp mills are rarely built. Therefore, Chinese papermaking companies have brought huge demand growth to the global pulp market.

At present, about 50% of the pulp in the global pulp supply is commercial pulp, and about 50% is self-sufficient integrated pulp and paper plants. It can be said that the development of China’s papermaking industry has completely changed the pattern of the global pulp market.

Workers load pulp for export at the dock