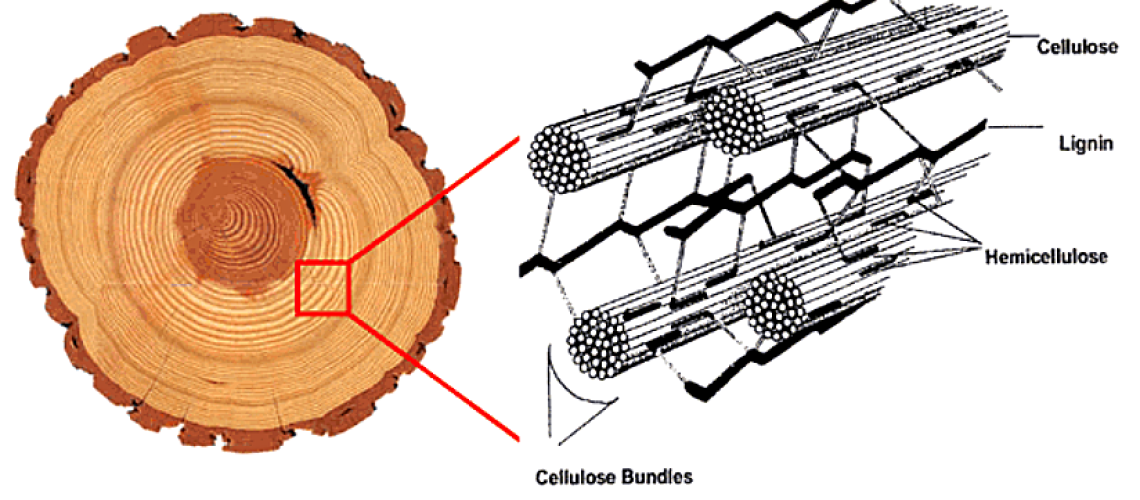

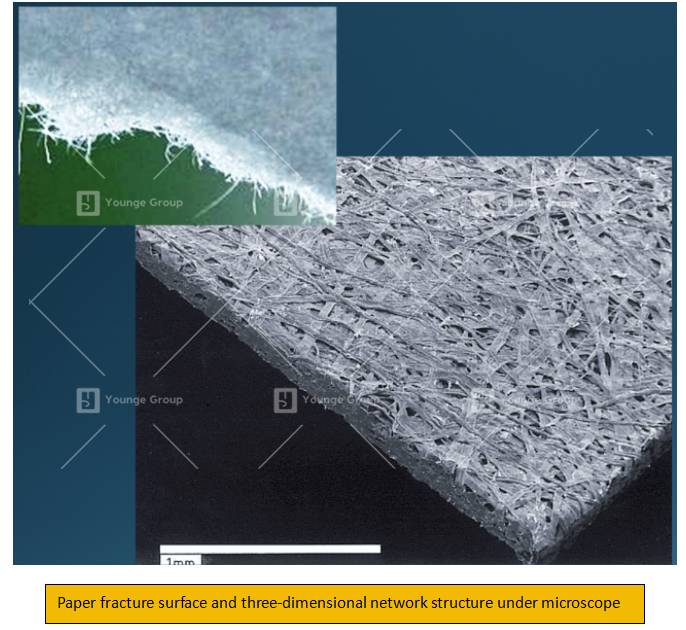

Paper is an indispensable material in our lives. The structure of paper is composed of fibers, fiber fragments and fine fibers, filler particles, polymers and other chemicals. Usually, the main component of paper is natural cellulose fiber, and the main body is a three-dimensional porous structure composed of fibers.

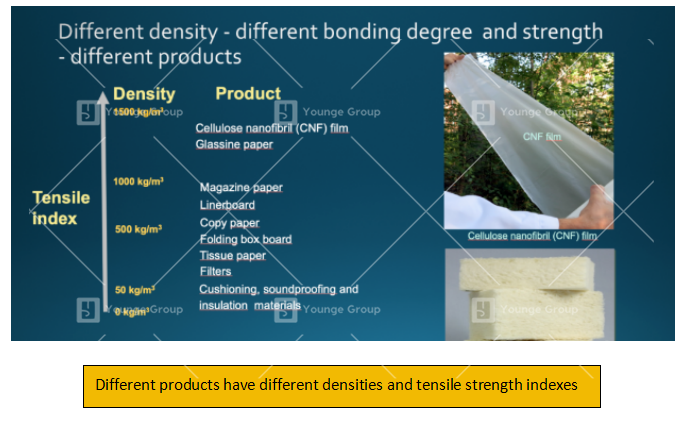

Density is one of the important performance indicators of materials. It is the weight of the material per unit volume, usually expressed in kg/m3. In the pulp and paper industry, the “bulk” often mentioned is the reciprocal of density (also known as tightness), which is the ratio of the thickness of the paper to the grammage per unit area.

Different papers have different densities, forming products with specific properties. In the figure below, the density of the nano-fine cellulose film is greater than 1000 kg/m3, while the density of the cushioning material made by special foam technology is only about 50kg/m3. The higher the density of the paper, the better its tensile strength, because there are more bonds between the fibers.

Tensile strength of paper

The tensile strength of a material refers to the maximum tensile force that a unit width of paper or paperboard can withstand before breaking under the conditions specified by the standard test method. The tensile strength is generally expressed by dividing the tensile force value tested on the tensile tester by the sample width, which is called the absolute tensile strength of the paper, and the unit is kN/m.

Under the same structure and chemical composition, the absolute tensile strength of paper is in a certain positive proportional relationship with the quantitative. Therefore, when comparing different paper products, we often deduct the influence of gram weight and focus on discussing and studying the tensile index (tensile strength divided by gram weight). The higher the tensile index, the more likely it is to produce products with lower gram weight, which is in line with the development trend of lightweight and efficient use of materials.

Tensile strength is also one of the most commonly used paper strength indicators. For most papers, tensile strength is of great significance in production and application. For example, on-site paper mills often break due to insufficient paper strength, or during paper printing or reprocessing, the longitudinal tension of the paper is greater than the tensile strength of the paper, resulting in paper breakage. At the same time, within a specific range, the tensile strength of paper also has a certain correlation with other strength indicators.

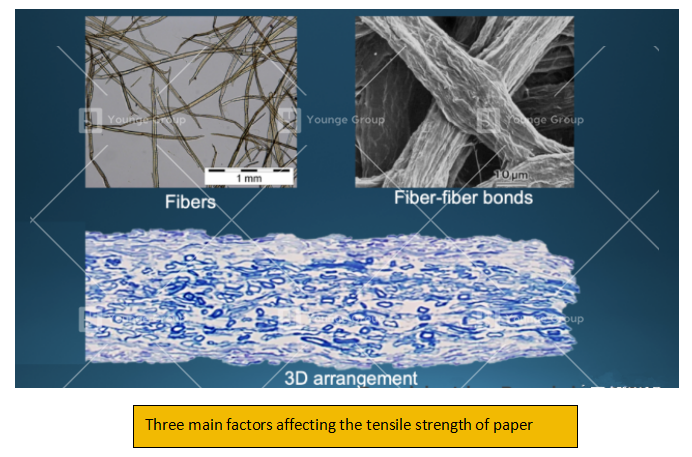

Three main factors

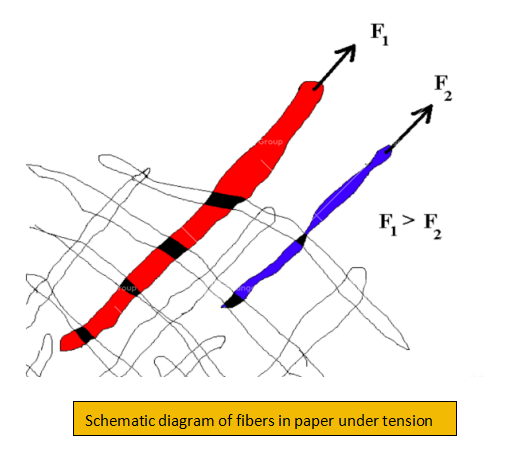

The tensile strength of paper is related to three main factors: fiber strength, fiber bonds strength and fiber 3D-arrangement.

- The fiber strength itself is often much higher than the paper strength. The strength of natural cellulose fiber itself is even greater than the unit weight of stainless steel. Therefore, the fiber strength gives the upper limit of the paper strength. The fiber-to-fiber bond is often damaged before the fiber breaks.

- The three-dimensional network structure of paper refers to the distribution of fibers in the thickness direction and horizontal plane. For some products with high bulk, it is even necessary to discuss its interlayer structure. The fibers are oriented in the horizontal network structure distribution. Therefore, the longitudinal (machine direction, MD) tensile strength of paper is often significantly greater than the cross direction (cross direction, CD) tensile strength.

- The most critical factor affecting the tensile strength of paper is: the bonding strength between fibers, which refers to the strength of the molecular bonds formed between fibers in contact with each other, including hydrogen bonding. The greater the bonding strength between fibers, the greater the tensile strength of the paper. The bonding strength between fibers is related to factors such as fiber length, fiber width, fiber coarseness, specific bonding area, and relative bonding area.

Fiber length and width

Fibers are plant cells with a large length-to-width ratio (50-100). Fiber length is the most important characteristic of papermaking fibers. Longer fibers can form more bonds with other fibers, so they are more firmly bound to the paper sheet than short fibers.

Usually, the length of natural cellulose fibers for papermaking is about 0.6mm-2.5mm. Hardwood fibers are shorter than softwood fibers, and their length distribution range is narrower. The dry and wet tensile strength of paper increases with increasing fiber length.

Fibers usually collapse into ribbons during the papermaking process, and fiber width can be used to predict the potential surface area for fiber-to-fiber bonding. The wider the fiber, the larger the bonding area between fibers may be. Long and wide fibers have a larger surface area to form more bonds with other fibers, thereby obtaining greater strength.

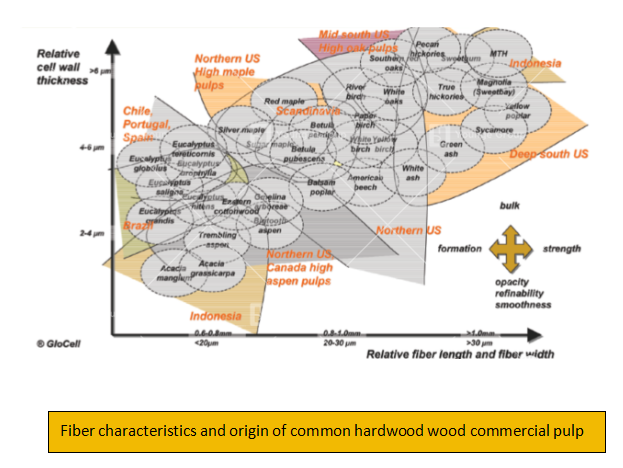

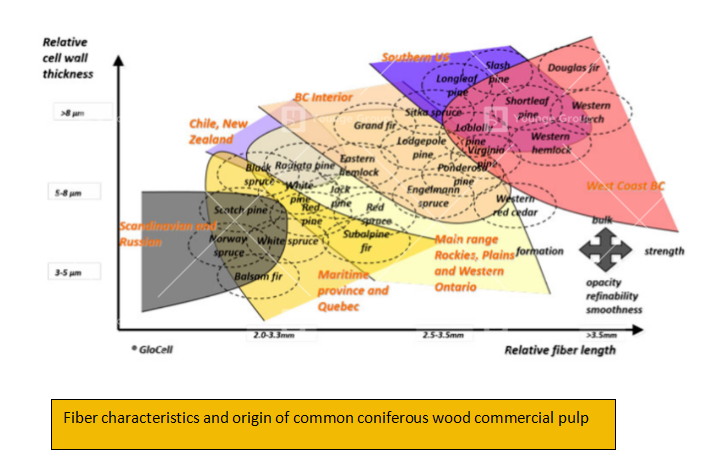

The following two figures show the fiber characteristics and origins of common softwood and hardwood commercial pulps. It provides a certain reference for papermaking companies to choose suitable raw materials.

Fiber coarseness

Another important factor affecting the strength of fiber bonding is fiber coarseness. Fiber coarseness refers to the mass (mg) of the absolute dry fiber per unit length, in mg/m. Generally, thick-walled cells have greater fiber coarseness than thin-walled cells. The reciprocal of fiber coarseness is the total length of a certain commodity pulp fiber per unit mass. When the mass of paper is constant, the smaller the fiber coarseness, the more fibers there will be in the paper, the more bonding area between the fibers will be, and the greater the tensile strength of the paper will be.

Fiber properties (including fiber length, width, coarseness, curl and kink, etc.) can be automatically tested and analyzed by fiber analyzers, such as the FiberMaster fiber analyzer of L&W in the United States, the Kajaani FS300 of Metso Automation in Finland, and the FQA fiber quality analyzer of Optest in the United States.

Specific bond strength

Specific bond strength (SBS) refers to the strength of the bond between fibers. The strength of paper mainly depends on whether the fibers that make up the paper are well bonded together, that is, the number and strength of the bonding points.

The specific bonding strength between fibers depends on the surface chemical properties of the fibers, as well as the molecular structure and microstructure of the fiber bonding surface. The bonding between fibers is mainly the van der Waals force between molecules and the hydrogen bonding between cellulose molecules; other effects, such as the chemical bonds in cellulose molecules and the acid-base effects between them, and the entanglement of polymer chains can also play a certain role in some cases.

The greater the specific bonding strength (strength per unit bonding area), the greater the bonding area and number between fibers, and the greater the tensile strength of the paper. This also means that we can improve the fiber bonding by either increasing the bonding area between fibers, increasing the specific bonding strength, or increasing both at the same time. However, different methods will have different effects on other properties of paper, which we will discuss in the series of articles “Talking about Papermaking from Scratch”.

Relative bond area

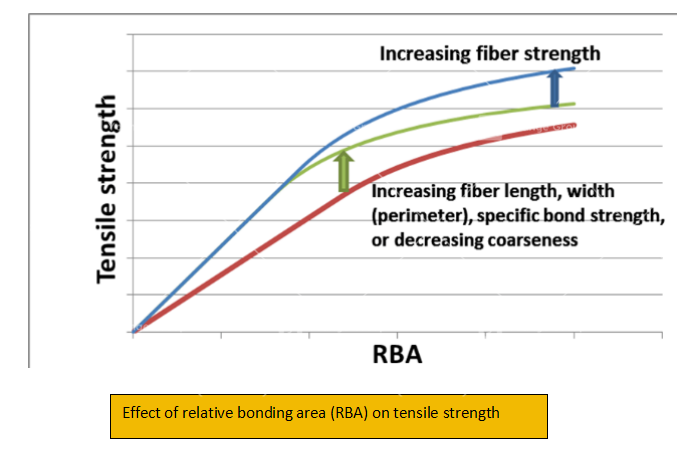

Relative bond area (RBA) describes the percentage of fiber-to-fiber bond area to total fiber surface area. This concept is strongly correlated with paper density.

As shown in the figure below, the tensile strength of paper increases with its relative bond area. At a certain relative bond area, increasing fiber length, width, specific bond strength, or reducing fiber coarseness can further increase the tensile strength of paper. The effect of fiber strength on paper tensile strength is only apparent when the relative bond area of the paper is high.

The fiber-to-fiber bond area can be increased by using longer fibers (such as softwood pulp fibers). Relative bond area can also be increased by using fibers with smaller coarseness, beating the fibers, using higher wet pressing pressures, etc.; fiber bond strength can often be improved by adding dry strength agents such as starch.

Conclusion

The tensile strength of paper is closely related to the fiber strength, the bonding strength between fibers and the three-dimensional network structure of fibers. Among them, improving the bonding strength between fibers is the most critical factor in improving the tensile strength.

To improve the tensile strength of paper, we can start with the selection of raw materials and consider the influence of different fiber characteristics such as fiber length, width, and coarseness); we can also optimize and adjust the papermaking process conditions, such as appropriate pulping of fibers, increasing the pressure of wet pressing, and changing the drying conditions (drying network tension, heating temperature curve, etc.), so as to improve the relative bonding strength between fibers and the relative bonding area in the paper web; in addition, adding certain chemical additives such as starch in the papermaking process can also achieve the purpose of improving the bonding strength between fibers.

The papermaking industry is an industry that combines theory with practice. It is hoped that these basic theoretical knowledge can help friends in the industry, especially front-line workers, to understand the reasons behind the process and production in a comprehensive manner and better guide actual production operations.