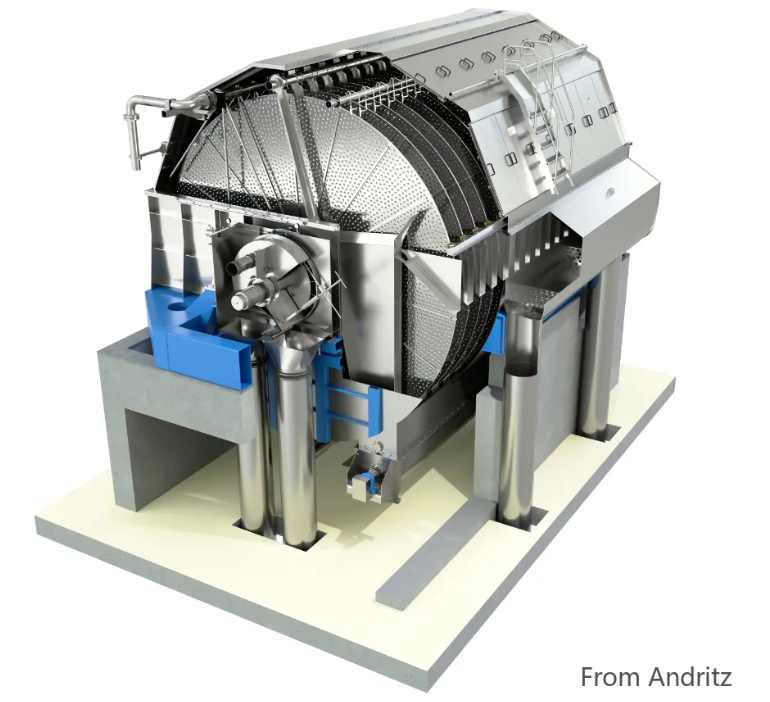

What is a white water multi-disc filter?

In simple terms, a white water multi-disc is a white water system filter, and its filtering effect is directly related to the operation of the paper machine. So everyone can see at a glance how important the white water multi-disc is to the paper machine.

The forming net takes away a lot of fine fibers during the dehydration process. The function of the white water multi-disc is to recover and concentrate the fine fibers in the white water, and then filter the white water into filtrate of different concentrations for recycling.

A good white water multi-disc should have the ability to continuously, stably and efficiently treat white water, and can also calmly deal with fluctuations in white water concentration and flow. Not only can it cleanly recover fine fibers, but it can also ensure the stability of the concentration of the distributed filtrate, and it must also be simple and easy to operate, with a low failure rate.

New process design

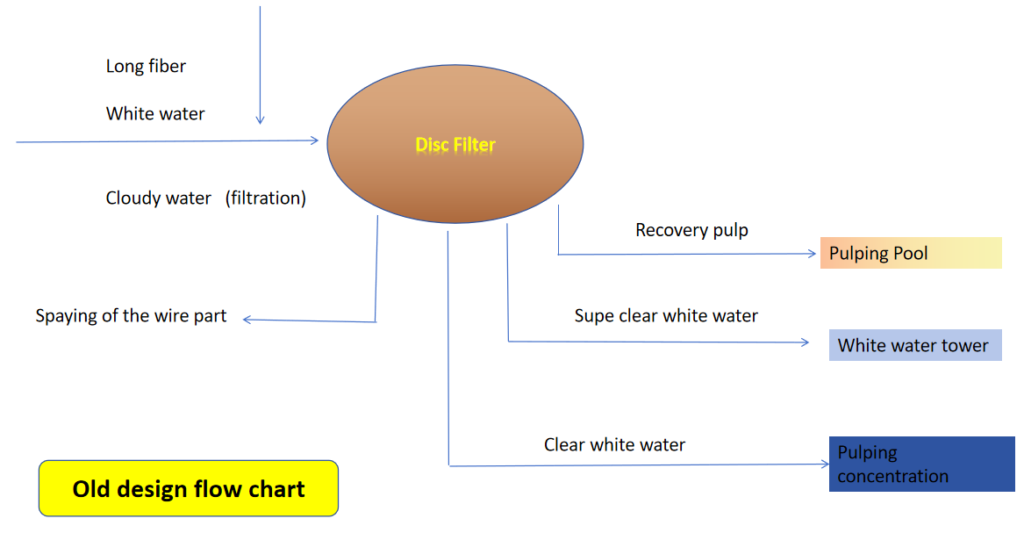

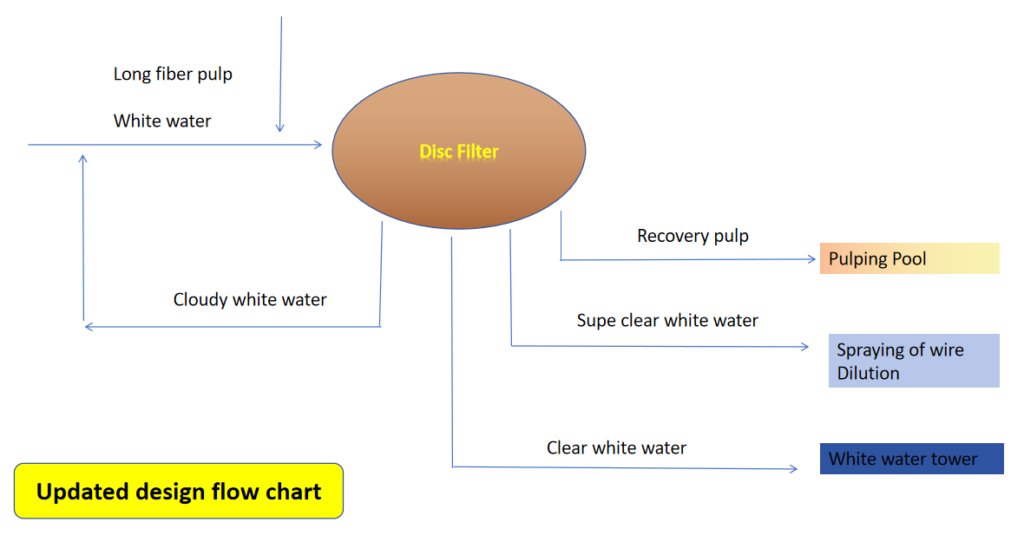

With the update and iteration of white water multi-disc and the characteristics of raw material changes, the process design of white water multi-disc has also undergone the following changes:

In the design of the new and old processes, the biggest change is the treatment of the multi-disc turbid filtrate (highest concentration). The original design was to use the turbid filtrate for net spraying after secondary filtration. Such a design not only requires an increase in the investment in the filtration system, but also faces the problems of nozzle blockage caused by the unexpected collapse of the filtration system (filter damage).

The new design is to return the turbid filtrate to the multi-disc again, and collect and concentrate the fine fibers and ash in the turbid filtrate again. The cleanliness of the filtrate is greatly improved. The system has a virtuous cycle. However, if the white water multi-disc is not in good condition, if you want to make such a change, you still need to consider the whole picture. There are many other factors that affect the operation of the white water multi-disc. It is not necessarily successful to change the direction of the turbid filtrate.

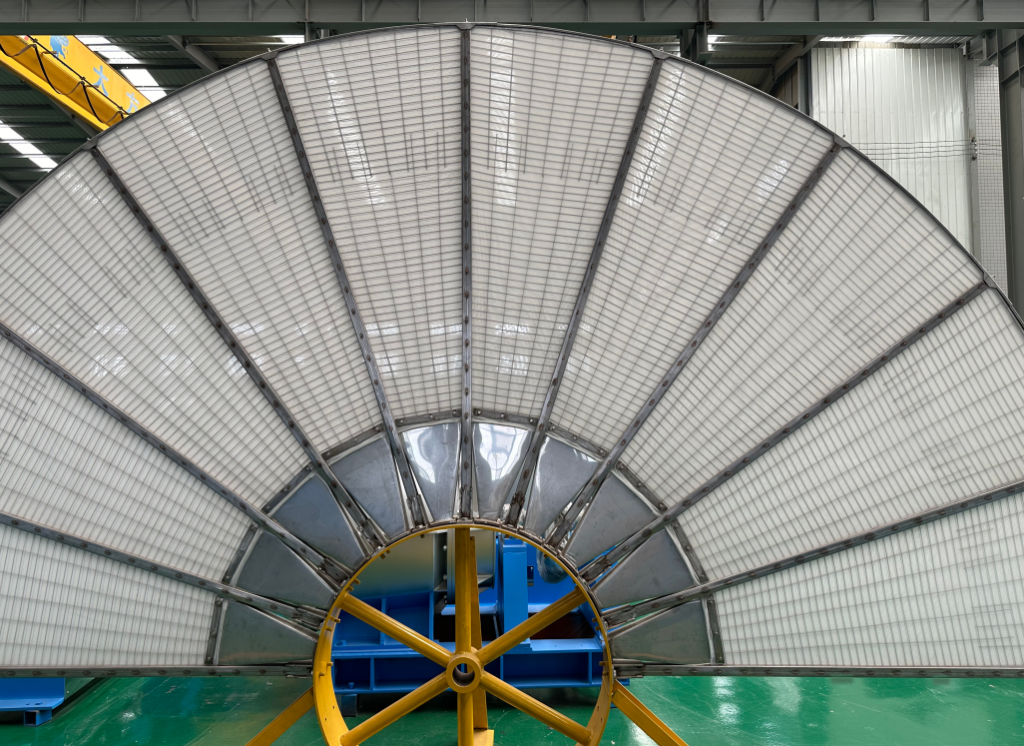

Update of fan-shaped discs

As an important component of dehydration and concentration, the fan-shaped discs are made of polyester mesh in traditional multi-discs, which are easily deformed by changes in pulp temperature, affecting the dehydration efficiency. Secondly, the ash content in white water is high, and the organic/inorganic matter in white water can easily cause the mesh to stick, resulting in poor processing capacity of the multi-disc. After long-term use, the polyester mesh is also prone to aging and damage. As long as a hole appears in a filter bag, it will affect the concentration of the entire recovered pulp and filtrate, so-called “one rat shit spoils the whole pot of porridge”.

Therefore, in the face of current raw material changes and capacity increases. Most of the latest designs of white water multi-discs use steel wire filter bags. The influence of pulp temperature on the filter bag is completely avoided, and the acid/alkali solution will not be disturbed when cleaning the multi-disc blades.

In addition, the filter bag made of steel wire mesh can also be made into a wavy shape. The same size of multi-discs can expand the contact area between white water and blades by 25-30%, and the processing capacity is further improved.

Ton of paper clean water consumption

In addition to fiber recovery, the most important factor in measuring the quality of a white water multi-disc is whether the distribution and treatment of the filtrate can meet the design requirements. The filtrate of the white water multi-disc is used for the thickening water of the pulp and papermaking. If the filtrate quality does not meet the standard, long-term use will not only cause the pulp concentration to deviate, but also cause the system to breed bacteria, form rotten pulp, and the ash content of the pulp is high, affecting the high-speed and stable operation of the paper machine. This is especially obvious in “black paper” paper machines.

For a good white water multi-disc, the clear filtrate should be within 60ppm, and the ultra-clear filtrate should be within 35ppm. If there is a need to save water, qualified ultra-clear filtrate can be used as auxiliary dilution water, and the clean water consumption per ton of paper can be controlled at about 4 tons. (Use with caution in white cardboard machines, the color of white water will affect the whiteness and paper surface of white cardboard).

Conclusion

As the processing center of the entire paper machine white water system, the white water multi-disc should be inspected and maintained during the annual maintenance period, especially the wear of each spray water nozzle, the fan seal pad and the vacuum distribution seal, etc. These are all areas that need to be inspected. If there are any abnormalities, they should be replaced in time to keep the multi-disc in good condition!