Toilet paper is a thin paper used for daily hygiene in people’s lives, with good softness, absorbency, cleanliness and other characteristics. So, on what kind of equipment is the daily paper we use every day produced?

Types of toilet paper machines

A toilet paper machine produces paper with low grammage, soft texture, strong water absorption and not easy to break, which can meet the required functions and then be transformed into products and accepted by consumers and buyers in the market. In fact, toilet paper machines can not only produce toilet paper, but also produce daily paper such as facial tissue, napkins, and kitchen paper towels.

According to the different design structures of the net part, toilet paper machines can be divided into: Crescent Former(mainly introduction in this article1), vacuum round net toilet paper machine, inclined net toilet paper machine, composite paper machine, etc.

Among them, the crescent toilet paper machine accounts for about 65% of the imported toilet paper machines that have been put into production and are still in operation in China, and is a typical representative of toilet paper machines.

The crescent type actually refers to the design method of the forming net part, which was developed and designed by Kimberly-Clark (KC) in the United States in the 1960s. After the expiration of KC’s patent in 1988, many other companies began to manufacture and use crescent forming paper machines, which promoted the widespread application and promotion of this technology.

According to the different drying methods, there are two main types of common toilet paper machines: one is the dry crepe tissue machine (DCT), which uses a Yankee dryer for drying; the other is the through air dryer (TAD) toilet paper machine.

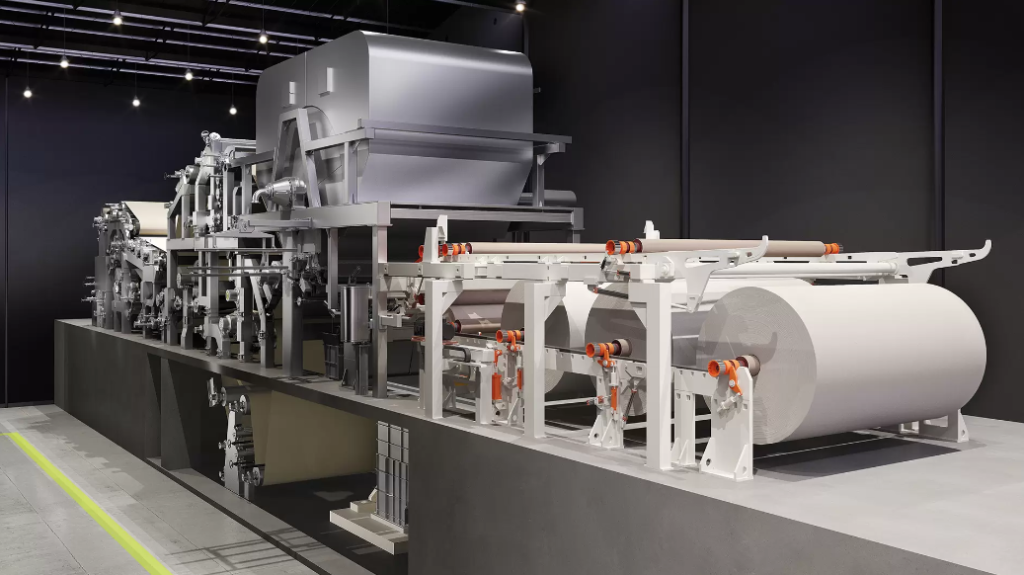

Crescent dry crepe machine for toilet paper.

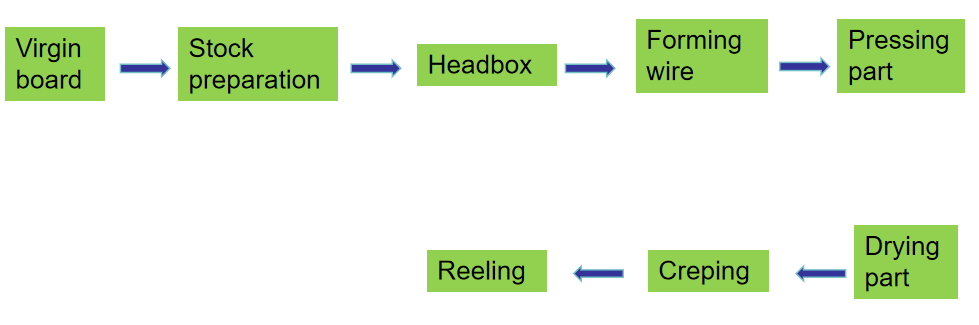

The basic process of toilet paper production

From raw materials to the production of a qualified toilet paper, it usually goes through the basic process shown in the following figure:

- First, the pulp sheet (usually virgin wood pulp) is transported to the hydraulic pulper, where it is mechanically dispersed into single fibers;

- Since the virgin wood pulp itself is very clean, the pulp preparation system for toilet paper is usually relatively simple, and does not require the removal of slag, purification, screening and other processes and equipment in the conventional papermaking pulp preparation system. The high-concentration slag removal and the front screen in the flow system mainly play a protective role in removing foreign matter from entering the pulp preparation system. After the pulp preparation process, a clean pulp suspension of a certain concentration is prepared;

- The pulp concentration entering the headbox is generally about 0.5%. The main function of the headbox is to keep the fibers in the pulp suspension fully dispersed, thereby ensuring the uniformity of the paper web. At the outlet of the headbox, the dispersed fibers are sprayed onto the forming net and dehydrated to form a wet paper web;

- The difference between toilet paper machines and other paper machines lies mainly in the paper machine units such as the wire section, the press section or the pressing section, the drying section and the wrinkling section. Therefore, we will introduce them in detail below;

- After the paper web is dried, it is rolled up, and the rolled paper is transported to the slitting machine, and the corresponding toilet paper products are obtained by slitting and packaging according to the required size.

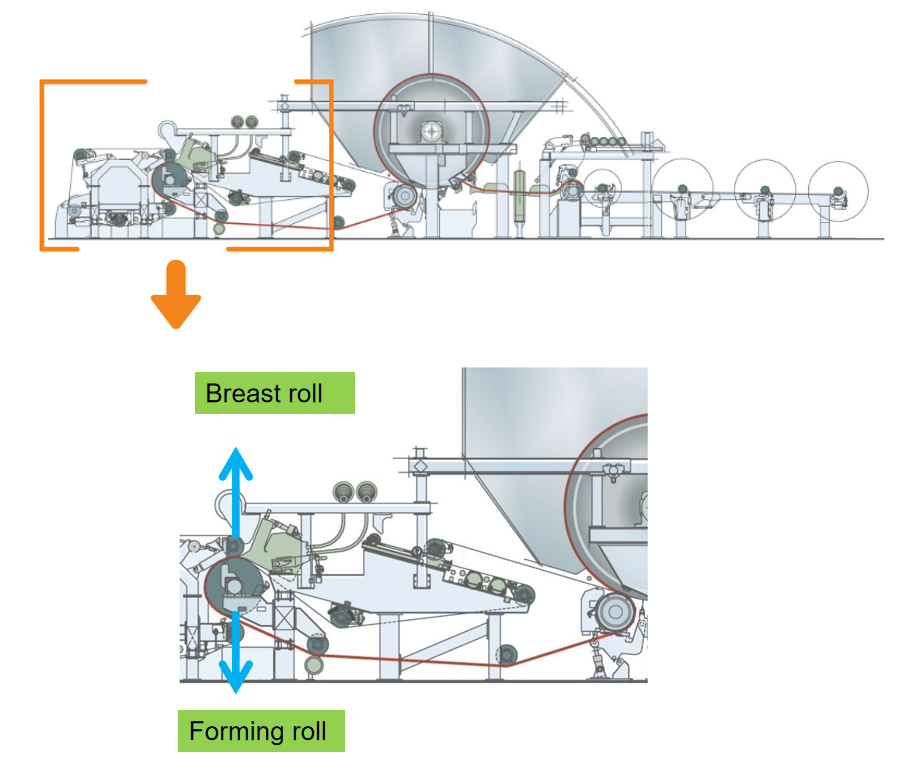

Forming Part:Crescent shape

During the crescent forming process, the slurry (mainly water and fiber, etc.) that has passed through the slurry preparation system is ejected at high speed through the headbox. The slurry is squeezed and dehydrated between the forming wire of the breast roll and the felt of the forming roll (as shown in the figure). The pulp fibers adhere to the felt to form a wet paper web, which is then taken away by the felt.

There are two kinds of fabrics in the general crescent forming wire section: a forming wire and a pressing felt. The front end of the crescent former clamps the “wet paper blank” between the forming wire and the felt. The initial drainage occurs around this forming roll, and the tension of the forming wire determines the drainage capacity. The drainage pressure P is described as P=T/R, where T is the tension of the forming wire and R is the radius of the forming roll.

The red line represents the wet sheet

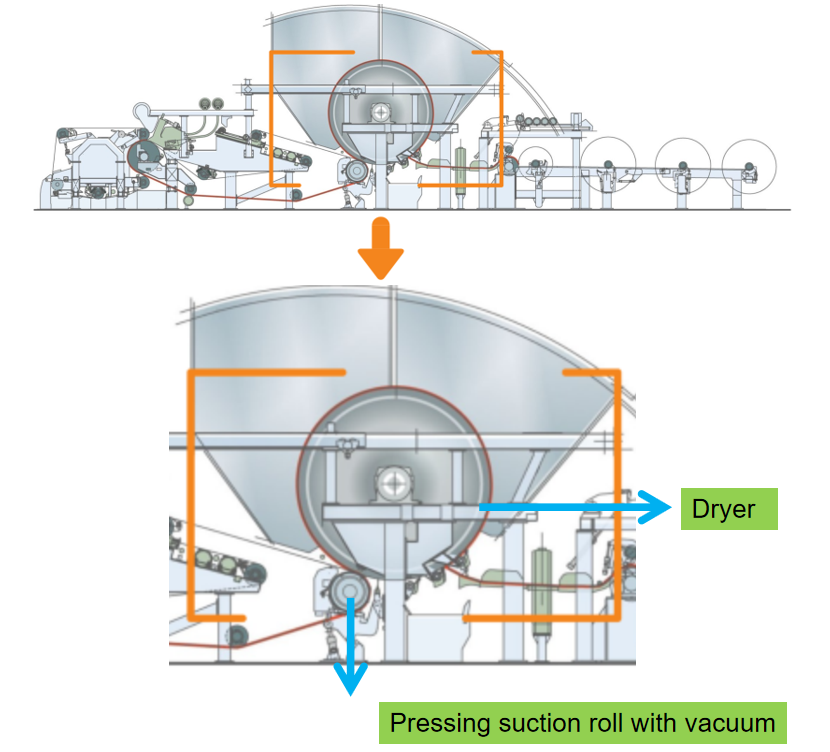

Press Dewatering

Press dewatering absorbs or attaches the web to a felt and then transfers the web to the Yankee in the first nip. The first press roll is usually a transfer roll with a wide suction zone of 80-110°. In this suction zone, water is removed through the felt. The web dryness is increased to about 25% before the press and usually rises to about 40% or more after the press.

In the past 10-15 years, a new type of press has replaced the traditional press, which is called the shoe press. To reduce the water load entering the nip, a vacuum roll is used before the shoe press roll to remove water from the felt and increase the dryness of the finished paper. The shoe press can increase the web dryness before the dryer to 40-45%. To achieve this dryness, the nip load must be increased, which usually requires a Yankee dryer with a thicker shell to withstand the higher pressure.

Drying part: Yankee cylinder

On a traditional dry-creped tissue machine, the paper is dried on a large cylinder called a Yankee cylinder. Tissue is usually dried by directly contacting the paper web with the surface of the Yankee cylinder, which is heated by steam inside the Yankee dryer to evaporate the water from the paper forming.

The Yankee dryer not only provides the heat required for drying the finished paper, but also has three other functions:

- It transports the paper web during the drying process;

- It acts as a reverse “roller” during the drying process;

- It provides the basis for the creping process.

The drying capacity of a tissue machine is mainly affected by the size of the Yankee dryer. The fastest tissue machines have Yankee dryers with a diameter of 6m or more. Initially, the dryers on tissue machines were made of cast iron, but in the last twenty years or so, steel Yankees have developed rapidly. Now, steel Yankees can reach the same level of size as cast iron cylinders, and steel Yankees will dominate in the future.

In addition to the Yankee dryer, the gas hood can be heated up to 500°C, and hot air is blown over the paper web to increase the drying rate.

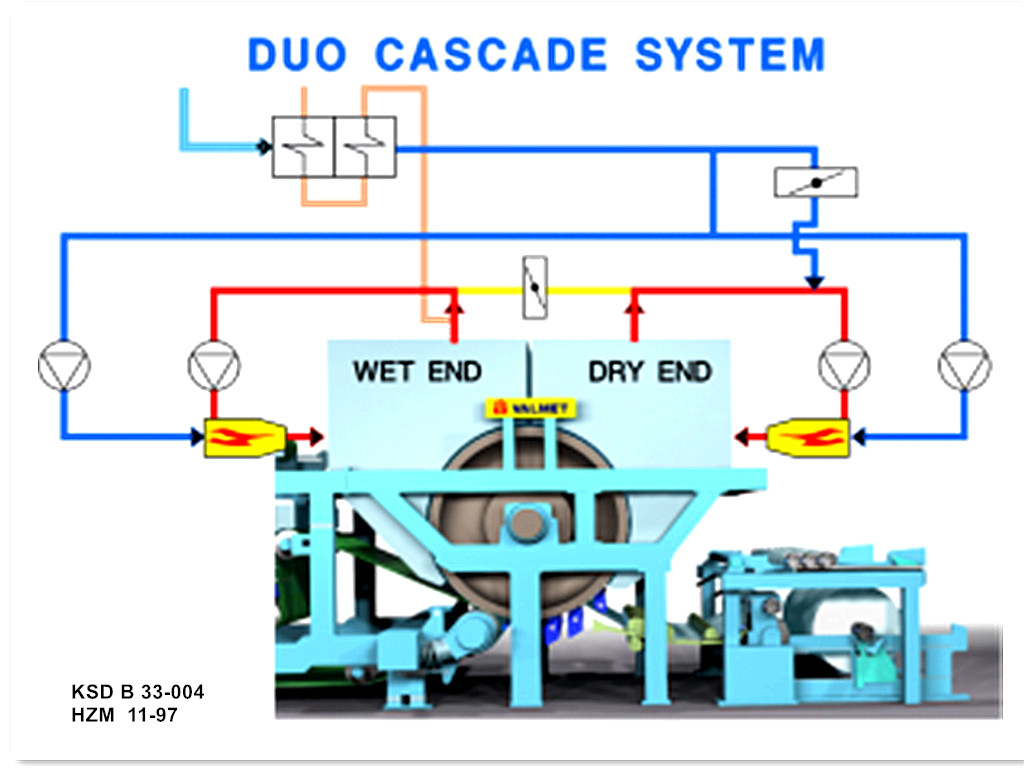

The most common hood system is called a “double breather system”. The hood is divided into a wet end hood and a dry end hood, both of which have a recirculation fan and a burner. The exhaust gas is extracted from the wet end hood because it has a higher air moisture content. The systems are connected by a damper, and the steam from the dry end hood can be brought to the wet end hood. A heat exchanger in the exhaust line heats the incoming air, which is mainly used for gas combustion.

Creping

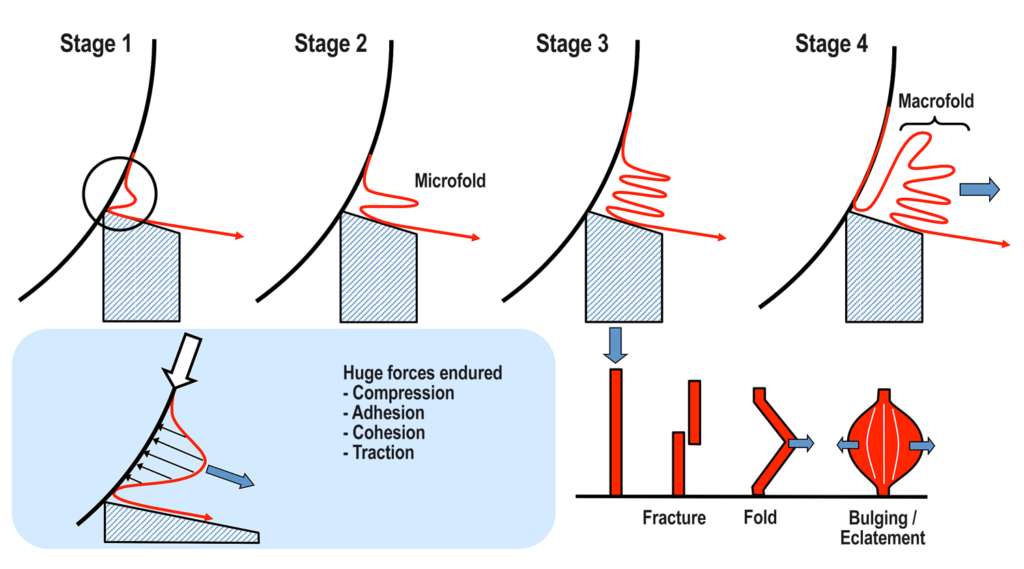

Tissue machines usually have three scrapers, with the creping scraper in the middle of the three scrapers. Before the creping scraper, a paper-breaking scraper is installed, which is used only when the creping scraper is replaced. Behind the creping scraper is the cleaning scraper, which removes excess fiber, paper powder and excessive coating from the surface of the dryer.

The creping process is a delicate operation that requires very high worker skills and requires a perfect balance between “the adhesion of the paper web to the dryer surface”, “the physical properties of the uncreped paper web” and “the force applied by the creping scraper”. Creping is basically done by perfectly peeling the paper web from the Yankee surface using the appropriate angle provided by the scraper. This means that the length of the paper web will be reduced, and this reduction in length is controlled by running the reel at a lower speed than the Yankee dryer.

The dry end of the tissue machine has a reel that takes up the finished paper web. As mentioned earlier, the reel runs at a lower speed than the Yankee because the wrinkling shortens the paper. The speed difference can be in the range of 10-30%. This speed difference is called the wrinkle ratio and is defined as [1-(reel speed/Yankee speed)] x 100%.

Tissue paper is usually produced at a wrinkle ratio of around 20%, while napkins have a lower wrinkle ratio, generally in the range of 10-14%. Facial tissue has a higher wrinkle ratio than both tissue and napkins, around 20-30%.

Softness of toilet paper

The softness of toilet paper is related to many factors. On the one hand, it is the selection and design of process parameters in the forming, pressing, drying, and wrinkling sections of the toilet paper machine; on the other hand, it is also closely affected by the proportion of pulp (addition of raw materials), the use of additives, and moisture control.

Development of toilet paper machine

International tissue machine manufacturers, such as Voith, Valmet, Andritz, etc., have invested huge resources and efforts in the technological updating and iteration of tissue paper machines, and have also launched a series of innovative products. The main improvement directions are concentrated on reducing costs, increasing efficiency and enriching the diversity of tissue paper products.

For example, Voith Toscotec’s INGENIA tissue machine saves about 35% energy compared to the common TAD tissue machine.

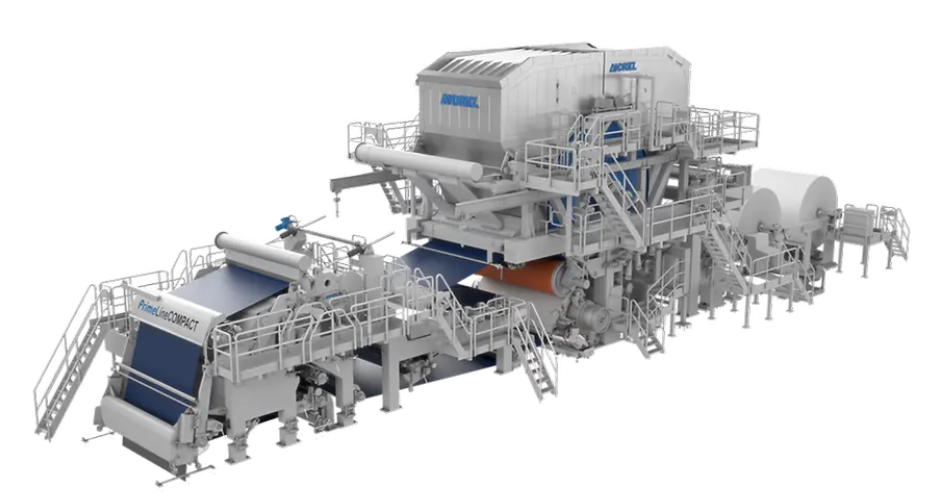

Andritz’s PrimeLineTEX claims that it can save 25% of fiber raw materials compared to dry creping, and can save up to 50% of energy compared to TAD tissue machines, and the paper machine is more compact and occupies less space.

Valmet’s Advantage Thru-Air (TAD) technology can save -35% of fiber while producing high softness and high bulk tissue products. In addition, depending on the pulp ratio and operating conditions, the energy consumption of tissue paper can be reduced to 3800 kWh/MT per ton of paper.