There is a way to analyze the factors affecting paper strength properties (such as paper elongation) is to start from the structure. As we all know, paper is a layered network structure composed of fibers bonded to each other. Therefore, the fibers that make up the layered network structure play a central role in the properties of the material.

Fibers obtained from different sources and different pulping methods are different. We can select fiber raw materials from aspects such as fiber morphology, chemical composition, fiber shape, strength and extensibility. In addition, fiber properties can also be further improved and adjusted through mechanical and chemical treatments.

In addition, fibers need to be connected to each other (bonded to each other). Without the bonding between fibers, there is no paper; without the connection, the fibers are just a pile of loose fibers that can be “blown away by the wind at any time.” Therefore, the connection (Joints) between fibers, that is, the bonding (Bonds) between fibers, plays an important role in the process of forming paper. The bonding between fibers can be direct bonding between cellulose and cellulose, or it can be an interaction with other chemical components, such as dry strength agents, and the cellulose surface of the bonded fibers.

In addition, the positioning and orientation of the fibers in the paper layer network, as well as how the resulting fiber network structure is changed, play an important role.

When testing and evaluating the strength of paper, the loading method (such as tension, compression, bending stress or a combination of these) and the test conditions (such as temperature, humidity, etc.) will also have an important impact on the results.

In summary, when we want to improve any strength properties of paper and understand the factors that affect strength-related phenomena, we can structure the problem into the following individual factors for analysis and understanding: fibers, fiber bonding, fiber network structure, and loading conditions for strength testing, as shown in the figure below.

Fibers

Fibers are the main structural component of paper. Usually, paper also contains other components, such as fillers or chemicals that change the properties of paper. In order to understand the properties of paper, we need to understand the role of fiber properties. In the previous article, we discussed the main fiber properties that can be used to understand how tensile strength and tear strength (or fracture toughness) depend on certain fiber properties. The main fiber properties are:

- Fiber strength

- Fiber length

- Fiber width or circumference

- Fiber roughness

By understanding these concepts, we can have a good basic understanding. Let’s take a deeper look at these properties, and we will also discuss other fiber properties.

Fiber strength

Fiber strength is important because it sets an upper limit on paper strength. Paper can only be stronger than the fibers that make it up. If the fibers are not well bonded or the paper structure is not optimal, the strength of the paper will be much lower than its ultimate strength.

The strongest individual fibers can withstand tensile loads of 20 to 50 grams and stresses of 1000 to 1700 MPa. Typical breaking strains (elongations) are a few percent. Fiber strength is particularly important for paper tear strength. Both pulping and papermaking processes affect fiber strength. Different types of damage can reduce fiber strength.

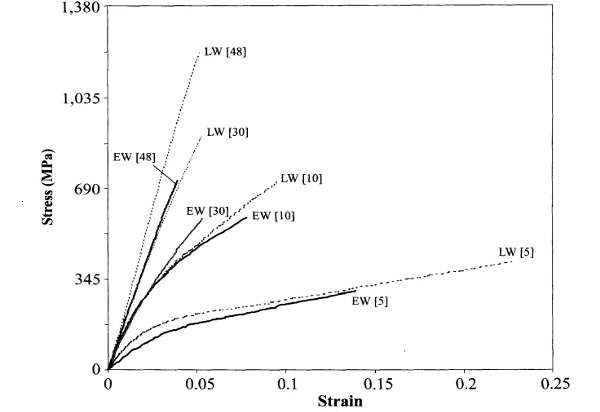

Stress-strain curves of earlywood (EW) and latewood (LW) fibers in different annual rings

The fibril angle of the fiber wall is important, especially the angle of the secondary wall. The smaller the angle, i.e. the more parallel the fibrils are to the fiber axis, the higher the axial strength of the fiber. Fibers from younger trees have higher fibril angles and thus lower fiber strength and higher elongation (Mott et al., 2002).

Chemical composition of fiber

Chemical composition also plays a role in fiber strength. Fibers can be considered as composite materials composed mainly of cellulose, lignin and hemicellulose. Cellulose is an important component that provides strength, while lignin and hemicellulose are the matrix materials.

If we calculate the tensile strength of paper as a function of fiber weight, gently removing lignin can increase the strength per unit weight without significantly affecting the breaking force of the fiber. That is, removing lignin reduces fiber weight without significantly reducing breaking force because lignin does not bear tensile loads.

However, lignin can withstand compressive loads and there is no need to remove it if the issue in question is the compressive strength of the paper.

Hemicelluloses do not bear loads, but they protect the fibers and have a positive impact on fiber strength, since in fibers with local discontinuities, such as bends, dislocations or pores, they may cause microfibrils to slide under stress and Reduces microfiber misalignment to help distribute stress.

Fibers with high hemicellulose content tend to absorb and retain more water and swell more than fibers with low hemicellulose or high lignin content. Hemicellulose on the fiber surface facilitates the bonding between fibers.

Fiber morphology

Fiber length is important because, as shown in the previous article, longer fibers are more firmly fixed in the fiber network of paper than shorter fibers because longer fibers can be bonded through more fiber bonding points. In addition, it takes more energy to pull out longer fibers than to pull out shorter fibers.

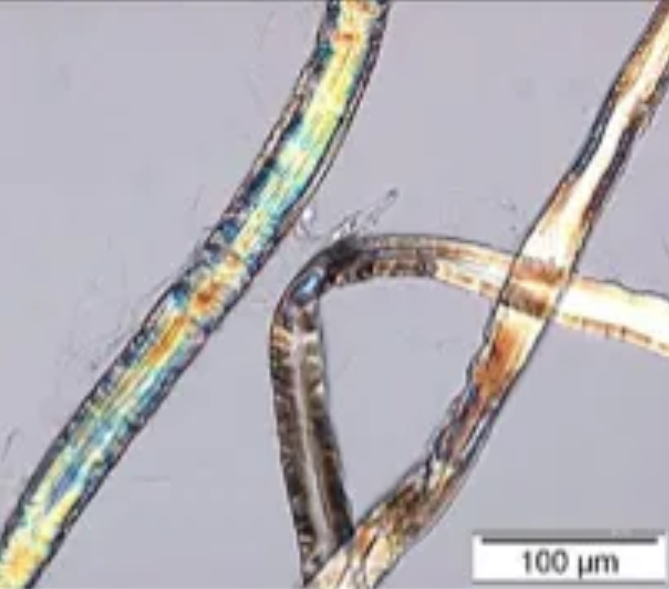

Fibers with multiple dislocations and micro-compressions. The color change is due to the change in the orientation of the microfibers (Zeng et al., 2012).

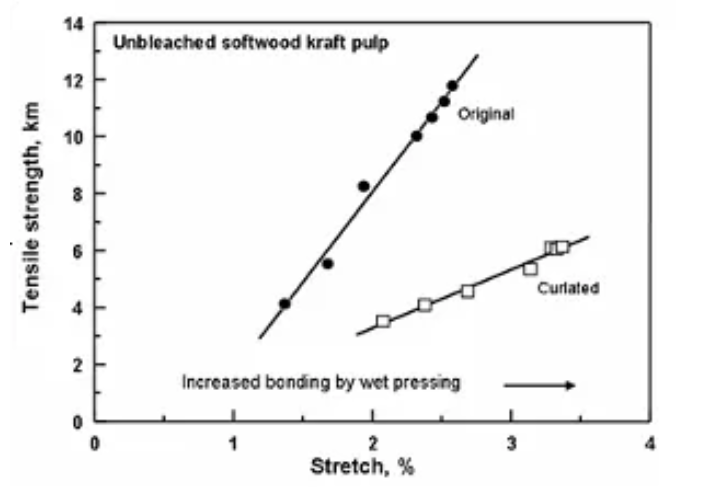

Fiber shapes such as non-straight, curled fibers with multiple bends and micro-compressions can reduce the strength properties of paper. Fiber curl can be increased through special treatments, thereby increasing the elongation at break of the paper.

Effect of fiber curl on paper strength (Seth, 2006)

Fiber width (or circumference), along with fiber length, determines the fiber’s external surface area and the area over which it can form bonds with other fibers.

Fiber Coarseness

Fiber coarseness, or the weight of a fiber per unit length, is related to fiber wall thickness and fiber flexibility. Paper is often graded based on basis weight (grams per unit area), so lower coarseness means the paper has more fibers (at a constant fiber length). Fiber flexibility reflects how the fiber fits into other fibers in the paper. Fibers with low flexibility produce bulky, less interfiber bonding, and lower strength papers.

Fiber bonds

As discussed in the previous article, fibers are the main component of paper. But for paper to have strength, the fibers must be connected to each other by forming fiber bonds. Otherwise, we just get a bunch of loose fibers that can be easily blown away by the wind. Fiber bonds can be thought of as the “weak link” in the strength of paper.

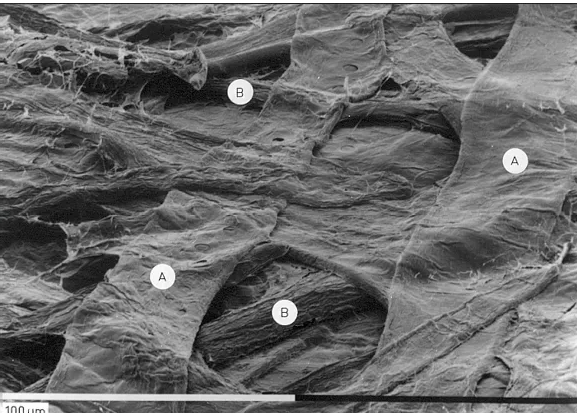

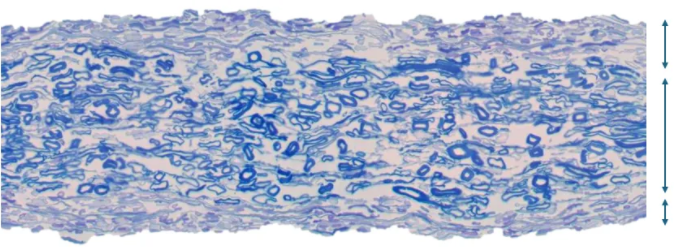

The fibers on the surface of chemical pulp paper form a network by bonding.

Fiber A is a thin-walled spring fiber,

Fiber B is a thick-walled summer fiber.

Traditionally, it has been thought that at the molecular level, the bonding between two fiber interfaces is based primarily on the formation of numerous hydrogen bonds. These hydrogen bonds are formed between the hydroxyl groups of cellulose (and other carbohydrates) as the paper dries from water. The hydrogen-bonding properties of cellulose mean that no additional adhesives or glues are needed to make strong paper. In addition to hydrogen bonds, other types of interactions contribute to the bonding between fibers.

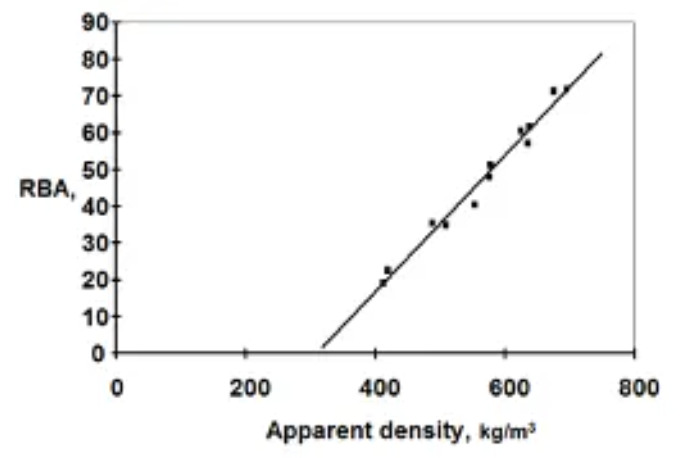

The bonding between fibers not only directly affects the strength of the paper, but also its optical properties. The more bonding between fibers in a paper, the lower its light scattering coefficient and opacity. This is because the bonding within the fiber reduces the fiber-air interface that can reflect light. At the same time, a higher relative bonding area (RBA) generally means a denser paper with less unbonded fiber surface and lower porosity.

Increasing paper density can increase the connection and relative bonding area between fibers

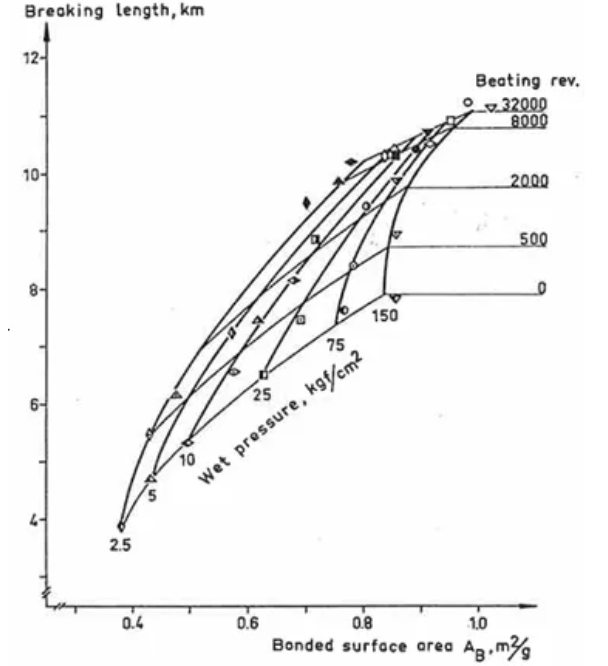

Both beating and wet pressing can increase the bonding area, but beating is more effective in increasing strength.

Three concepts related to inter-fiber bonding

Inter-fiber bonding is usually described by two concepts: 1) the strength of the inter-fiber bond (i.e., the force or energy required to break the bond, strength); and 2) the area of the inter-fiber bond. The inter-fiber bond strength divided by the inter-fiber bond area gives the third concept – 3) specific bond strength. These are theoretical concepts and difficult to measure.

In addition, a larger inter-fiber bond is not necessarily stronger than a smaller bond. This is because the bond strength between two fibers also depends on the structure of the bond and the properties of the fibers.

Studies have shown that two thick-walled summerwood fibers can form a stronger interfiber bond than two thin-walled springwood fibers, even though the springwood fibers form a larger bond area (Stratton and Colson, 1990). This is because the summerwood fibers have a thicker cell wall and thus a higher stiffness and a larger elastic modulus. This also suggests that the strength of the bond is the strength of some bonding structure, not just the interface strength between the two fibers.

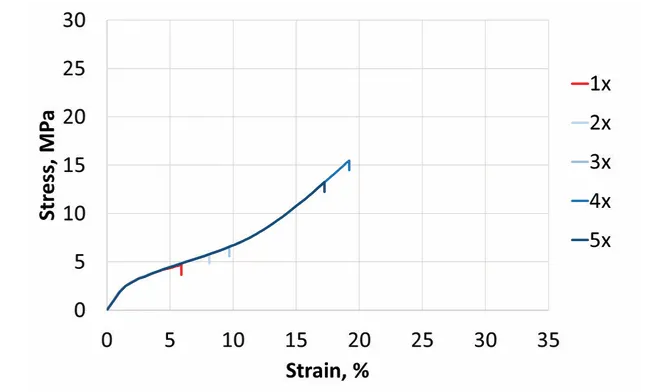

Effect of the relative increase in interfiber bonding strength on the stress-strain curve of paper based on simulations

It is well known that paper with a higher number of interfiber bonds is stronger than paper with only a few interfiber bonds. We can also assume that if there are a large number of hydrogen bonds between fibers, the interfiber bonds between two fibers are stronger than if there are only a few molecular bonds. This means that the fiber properties largely determine the stress-strain curve, but the strength of the interfiber bonds determines the end point of the stress-strain curve.

The number of bonds formed at the molecular level depends on the mechanical and chemical properties of the fiber surface. The fibrillated and swollen fiber surface contains hemicellulose gels that can form strong interfiber bonds with a large number of molecular bonds. The number of interfiber bonds can be influenced by refining and wet pressing.

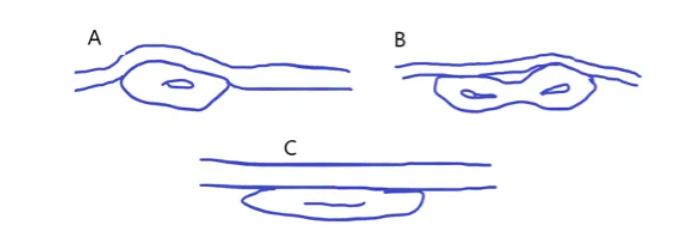

Examples of different fiber-to-fiber bonding structures.

A is a tangled bond,

B is a partial bond between fibers,

C is a flat bond

Several typical structures of fiber-to-fiber bonds can be seen in the figure above.

A) An entangled bond, which can be seen in paper that is allowed to shrink during the drying process. During tensile testing, high stresses will occur in the edge areas of the fiber bond, and fiber bond failure will begin in these areas.

B) The second structural feature is that the fibers are only partially in contact with each other.

C) A bond between two flat and straight fibers can transmit higher forces than the previous two because the stress is more evenly distributed within the bond. This bond can occur when the paper is dried under tension and cannot shrink, or when it is stretched in a wet state. In addition, the hygroscopic expansion of paper with this bond is lower than that of an entangled bond (A).

Improving interfiber bond strength

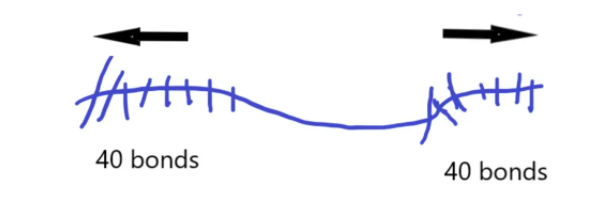

The typical interfiber bond strength between two chemical pulp fibers is about 5 mN (with wide variations). By using strength additives, this can be increased to 15 mN (Stratton and Colson, 1990). In theory, this means that if the fiber strength is 200 mN, we need 40 interfiber bonds of 5 mN strength at each end of the fiber to transmit a tensile force that can break the fiber.

Therefore, in most cases, the strength of the paper is limited by the fiber bonding, and only in papers with a high degree of fiber bonding is it limited by the fiber strength.

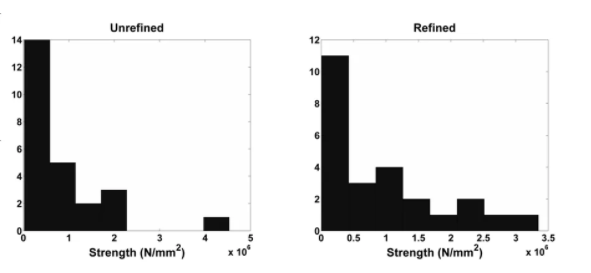

Fluctuations in bond strength between man-made fibers made from unrefined or refined fibers (Saketi, 2015). Shear stress is measured as the cross-sectional area, not the true bond area.

X-ray nanotomography studies have shown that the actual area of mutual bonding between two chemical fibers varies greatly, ranging from 6.4% to 85%, with an average of 58%, which means that more than 40% of the overlapping area of two fibers is actually unbonded (Sormunen et al., 2019). Refining reduces the relative unbonded area.

The contact area and the density of hydrogen bonds and other bonds can be increased by adding dry strength chemicals (such as starch, xylan, chitosan, guar gum, carboxymethyl cellulose, etc.) and nanocellulose. This shows that by changing the surface properties of the fibers or adding appropriate substances or chemicals to improve the actual contact area and increase the molecular bonding density, it is possible to change the mechanical properties of paper and bring new possibilities for improving paper strength.

This is especially important when we need to produce lower density paper structures or reduce the grammage of paper. In addition, the interfiber bonds should become stronger. However, the strength of the fiber wall interior, especially the bonds between the S1 and S2 layers, may actually limit the strength of the interfiber bonds.

Wet paper strength

Wet paper strength is a completely different area. We need to distinguish between two different wet strengths: initial wet strength, i.e. the strength of the paper web before it dries, and actual wet strength, i.e. the strength of the paper after it is wetted.

In the first case, hydrogen bonds have not yet formed or are very weak, but other weak interactions (such as van der Waals and capillary forces) still exist. Initial wet strength can be a factor limiting machine runnability.

In the second case, water breaks the hydrogen bonds between the fibers, which can be a problem in packaging and toilet paper. Therefore, we have two options: 1) slow down the penetration of water by hydrophobizing the fiber surface; 2) either protect the hydrogen bonds or replace them with stronger molecular bonds (covalent or ionic bonds). If the paper retains more than 15% of its dry strength after wetting, it is called wet strength paper.

Three-dimensional paper structure

Even though paper consists only of cellulose fibers, the structure of paper can vary in several different ways. We can talk about the three-dimensional arrangement of the components of the structure. In most cases, this means the position and orientation of the fibers in the x, y, and z directions of the paper, that is, the machine direction (MD), the cross direction (CD), and the thickness direction.

Paper uniformity or mass distribution in a plane

The basis weight of a paper varies in local areas. This variation is caused by two different processes:

1) Statistical process;

Statistical process occurs when individual fibers are randomly deposited on the forming wire. Some places have a large number of fibers superimposed on each other, and some places have only a small number of fibers.

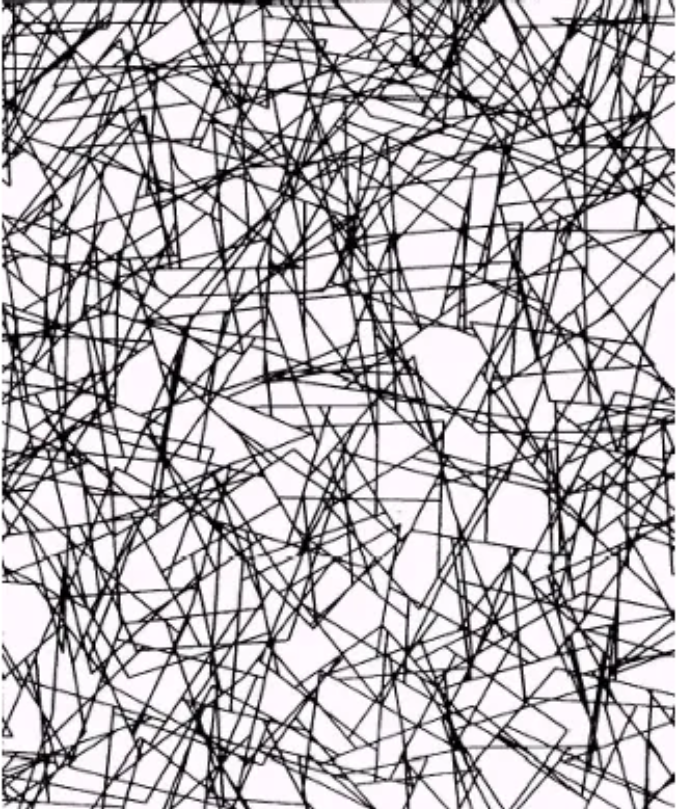

A sparse two-dimensional randomly distributed fiber network. The fiber ends are omitted for simplicity (Niskanen and Pakarinen, 2008)

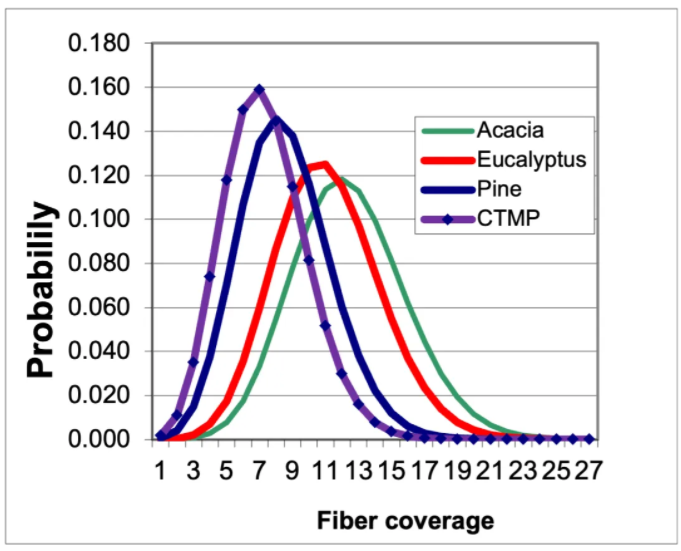

The number of fibers at each point can be called fiber coverage. Fiber coverage is randomly distributed and can be approximated by a Poisson distribution. A special feature of this distribution is that the mean and variance are the same. Using this knowledge, we can make a rough theoretical estimate of fiber coverage for different fiber types.

The theoretical fiber count (coverage) in a 50gsm paper is affected by the fiber type.

Here Acacia, Eucalyptus, Pine are chemical pulps, while CTMP is Spruce chemical mechanical pulp.

Coverage distribution is affected by fiber coarseness (= weight divided by length), or more specifically, fiber weight divided by the projected area of the fiber, which is the fiber length multiplied by its width. Using high coarseness fibers in a paper with a low basis weight makes it more likely that there will be points in the paper with zero fiber coverage, which is very detrimental to the paper.

However, in very low-concentration fiber suspensions, when hand sheets are made in the laboratory, individual fibers can flow with the water from the dewatering process, creating a self-healing effect. During the dewatering process, water tends to flow to areas of lower basis weight in the wet fiber layer, which will help bring more fibers to these areas that were originally less fiber-rich. Due to this self-healing effect, the formation of the paper may be more uniform than the statistical distribution predicts.

2) Flocculation process

This means that in aqueous suspension, the fibers tend to attach to each other and form aggregates or flocs. The results of flocculation can be observed in the produced paper.

The flocculation process is controlled by two types of factors: physical and chemical.

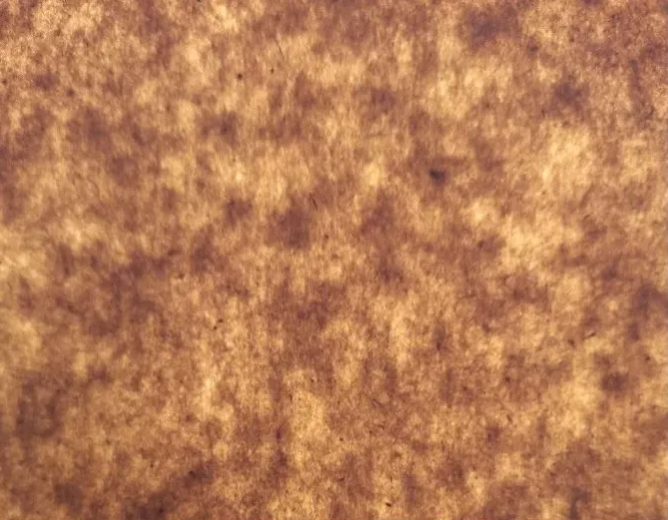

Perspective image of unbleached kraft paper, showing the uneven distribution of the material.

a) The typical papermaking concentration is about 1%, which means that the fibers can no longer rotate freely in the water, and their movement is restricted by other fibers, that is, the fibers are trapped by other fibers. The more fibers there are in a certain volume, the less ability the fibers can move independently, and the more likely they are to be trapped in clumps.

Kerekes developed a theoretical concept to predict this: the crowding coefficient.

The crowding coefficient is the average number of fibers contained in a sphere with the same diameter as the fiber length.

The crowding factor describes the number of fibers that can be contained within a sphere of the same diameter and fiber length. Typical crowding factor values are about 1-5 for laboratory handsheet consistency and 20-60 for headbox consistency. Friction is an important factor in keeping the fibers in the floes. The floes can be dispersed mechanically using high shear forces.

b) Chemical factors influence flocculation. The movement of smaller particles in particular is strongly influenced by their charge. If the particles have opposite charges (some positive, some negative), they attract each other and form flocculations. If the fibers have the same type of charge, they repel each other. Naturally, most pulp fibers have a negative charge or a small charge close to zero, but different additives can change the natural charge, such as retention agents, cationic starch, etc.

The result of fiber flocculation and the resulting inhomogeneities is a reduction in the strength of the paper. This is because the strength values are strongly influenced by the weak, low-basis weight areas in the paper. If the paper is calendered, the thicker, high-basis weight areas experience higher compression and they become more densified than the low-basis weight areas. The change in basis weight translates into changes in density, porosity, ink absorption.

Fiber Orientation

In laboratory-made paper, the orientation of the fibers is random.

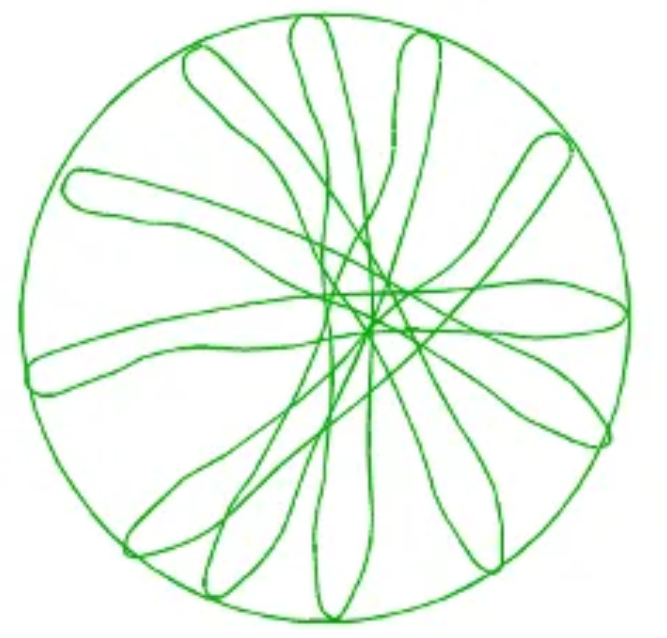

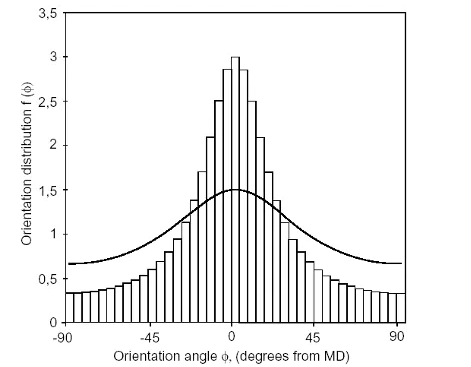

But in the headbox of a paper machine, the fibers tend to be oriented in the machine direction and in the flow direction. This means that there are more fibers oriented in the machine direction than in the cross direction (see Figure 5). The result of this orientation is that the strength in the machine direction (MD), such as tensile strength or stiffness, is also higher than in the cross-machine direction (CD).

Of course, the tear strength is higher in the cross-machine direction because there are more fibers in the cross-machine tear line than in the machine-direction tear. As we know, fibers expand and contract strongly in the cross direction, so the drying shrinkage and dimensional changes of paper are also more significant in the cross direction.

Fiber orientation distribution with high and low orientation

Z-direction or thickness variation

Almost all structural properties may also vary in the thickness direction. This is particularly evident in multi-ply paperboards composed of different fibers.

The figure above shows an optical microscope image of a cross section of a three-ply paperboard, where the top and bottom plies consist of chemical pulp and the middle ply consists of chemimechanical pulp.

However, even in a single-ply paper, the orientation of the fibers and the distribution of fine components and fillers in the thickness direction can vary significantly depending on the structure of the headbox and forming wire section of the paper machine.

Compared with sandwich paper machines, in Fourdrinier paper machines, the structure may be relatively unilateral because moisture is removed from one side. Unilateral moisture removal during the wet-pressing phase in particular leads to unilaterality of the density distribution.

Other phenomena affecting paper and its structure

The drying stage and other processes can also cause significant changes in the properties of the paper both inside and outside the plane.

Shrinkage, especially in-plane compaction (such as CluPak or Expanda type equipment), corrugation or folding can cause in-plane shrinkage or shortening of the paper, which can also cause wrinkling and warping of the paper, with a corresponding reduction in the paper’s strength properties. But the elongation is increased.

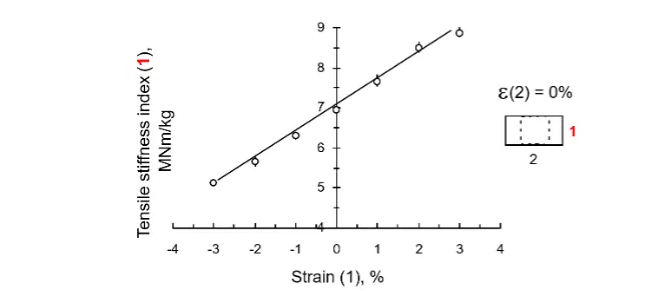

On a paper machine, the paper needs to have a certain amount of tension to ensure it transfers from one section to another. This means there is no paper shrinkage in the machine direction (MD), but there may be some wet stretch, which will have a positive impact on the MD tensile strength and tensile stiffness (see Figure 7) as well as the elastic modulus, but it will Reduce elongation at break.

In the cross direction (CD), the paper is not stretched and the shrinkage limit is very small, which will have the opposite effect on the tensile strength, stiffness and elongation of the MD, that is, the tensile strength and stiffness will be reduced, but the elongation will increase. The amount of paper shrinkage will vary across the paper machine, so that CD shrinkage is greatest at the edges of the paper and least in the middle.

Effect of wet stretching or shrinking (in direction 1) on the tensile stiffness in the same direction, while not allowing for shrinkage in the transverse direction

Conclusion

We have examined three structural aspects of paper and their impact on paper strength: fibers, bonding between fibers, and the three-dimensional structure of the paper. They have a strong relationship and interaction with each other during the papermaking process. Any changes we make to the fibers will also affect the bonding and three-dimensional structure of the paper. And vice versa: any changes we make to the three-dimensional structure of the paper will also affect the fibers and their bonding properties.

Thus, every step in the papermaking process, even a single section on the paper machine, will change the structure and properties at these three levels.