Traditionally, paper has been used to transmit and/or store information, but this is less and less the case with the advent of digital technology. Nevertheless, paper has almost always served as a surface to receive ink (printed paper) or other substances that will give the paper its final properties (e.g. extruded paper).

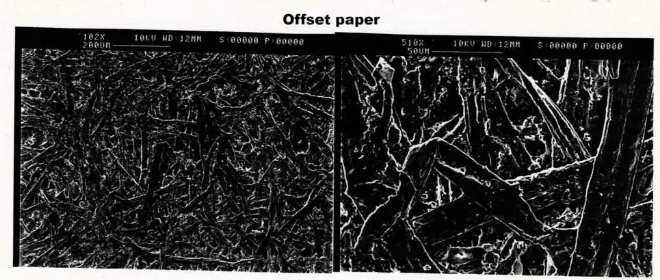

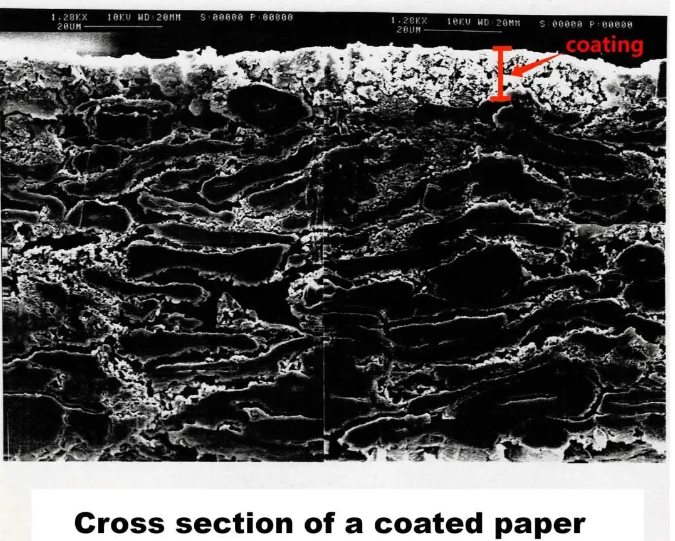

In a recent article, we outlined the main components of paper (e.g. cellulose, fillers and starch, Papermaking from Scratch : The Basic Composition of Paper), but these components are not sufficient to achieve the perfect surface required for the processing operation in the second step (printing, extrusion, etc.). Coating is one of the main ways to obtain the desired surface.

Coating changes the surface appearance of paper by applying different products that will improve the final characteristics of the paper after processing. Traditionally, coating is done with pigments and adhesives.

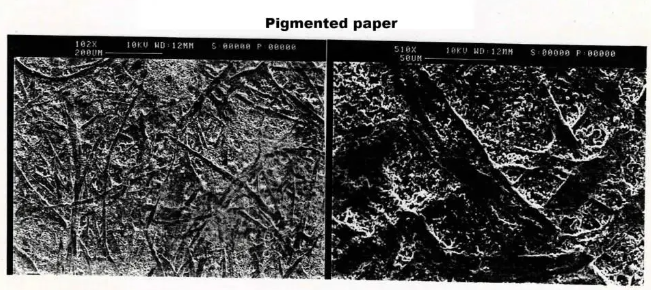

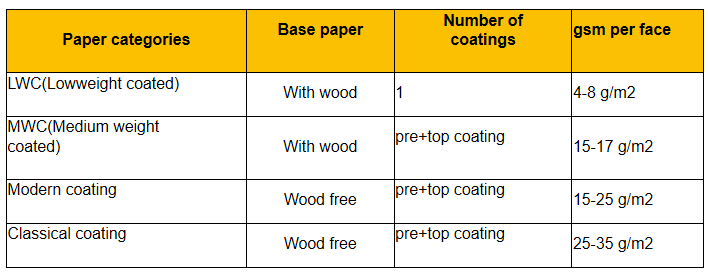

When the coating amount is small, we call it pigmented paper,

and when the coating amount is higher, we get real coated paper.

Printing and writing coating paper

With wood: Use pulp containing lignin in the base paper (mechanical pulp, chemical-mechanical pulp, etc.)

Wood free: Use only chemical pulp in the base paper

01 Pre-coating

Pre-coating prepares the topcoat by sealing the surface (reducing porosity).

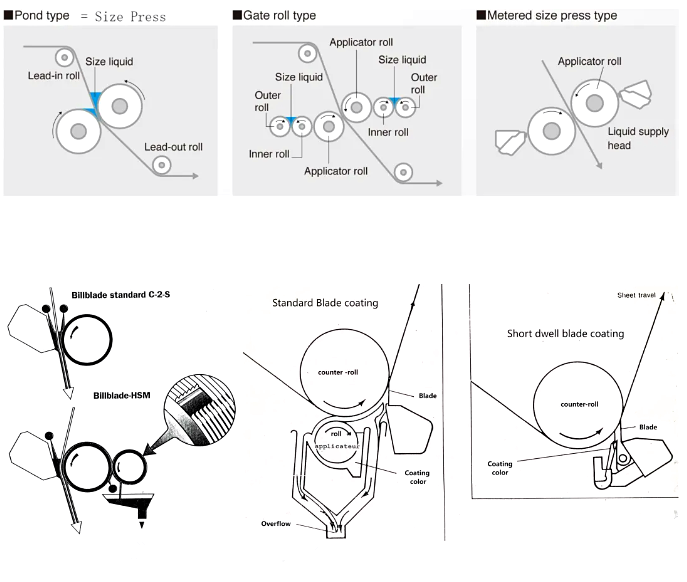

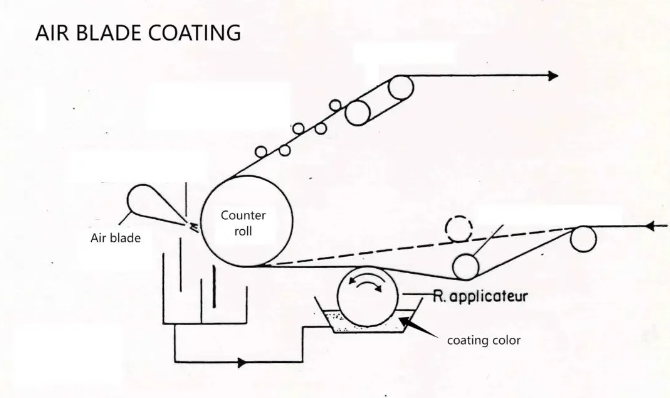

- Pre-coating can be done using different equipment: size press, gate roller, blade coating.

- The coating contains a high proportion of binder (adhesive is 20% to 100% of the pigment).

- The concentration of pre-coating coating is 20% to 50%.

02 Top coating:

The top coating will receive the ink during the printing process and the top coating is mainly applied by blade coating equipment (good coating quality and fast speed).

- The binder in the coating is 10% to 15% of the pigment.

- The concentration of top coating coating is 50% to 70%.

03 Matt coated paper:

Usually, these papers are not calendered (Bekk smoothness is 50 to 150s).

A large amount of calcium carbonate is used as a pigment in the coating of these paper grades.

04 High gloss coated papers:

These papers are calendered (using a supercalender) to achieve a Bekk smoothness of 700-2000s.

The coating contains a high proportion of clay (kaolin) to give a higher gloss.

Generally, high gloss coated papers have a lower brightness than matte papers: clay is usually less bright than calcium carbonate, and calendering reduces brightness.

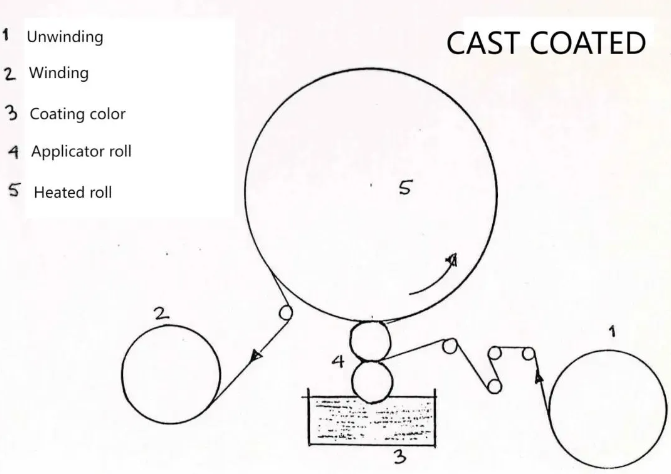

Coating method