Introduction

With the changes in the market environment, wide-width, high-speed, and high-capacity paper machines have gradually become the mainstream of the industry. In the context of increasingly fierce market competition, companies must pursue higher levels of energy conservation and environmental protection while ensuring product quality stability. Managers are particularly concerned about goals including higher speeds, higher production capacity, and more reasonable costs.

At present, the dryness of wet paper sheets in the paper forming section is usually 18%-23%, and the dehydration of the wire section accounts for more than 95% of the total dehydration of the entire paper machine, and the high-speed paper machine is even higher. After dehydration in the press section, the dryness of the wet paper sheet can be increased to 40%-50%, or even higher, depending on the paper type and pressing form.

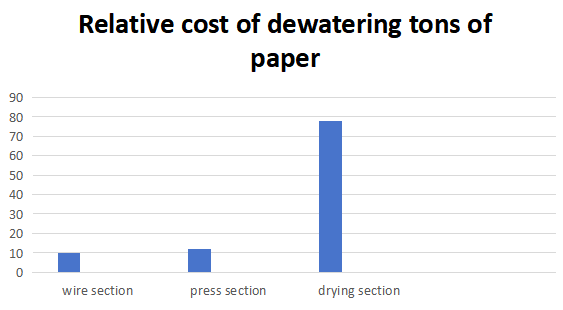

From an economic point of view, the relative cost of removing moisture from one ton of paper is distributed as follows:

Wire section: 10%

Press section: 12%

Drying section: 78%

It can be seen that dehydration by mechanical methods is obviously more economical than dehydration by evaporation. Therefore, improving the pressing efficiency to reduce the evaporation load of the drying section is a common pursuit of the industry.

Dryness and moisture content

The core function of the press felt is to mechanically dehydrate and solidify the paper sheet, improve the performance of the paper sheet, increase the strength of the wet paper web, and optimize the operating efficiency of the dryer section. The pressing process can be regarded as a continuation of the dehydration in the forming section, and its economic and quality benefits are very significant.

During the operation of the paper machine, the transverse dehydration must be uniform to ensure that the paper sheet entering the dryer section has a consistent moisture distribution. The moisture content of the wet paper sheet is usually expressed as dryness or moisture content, but the change in dryness is not equivalent to the absolute difference in moisture. For example, when the dryness of the paper sheet increases from 40% to 41%, although the dryness increases by 2.5%, the actual moisture content decreases from 1.50 to 1.44, a decrease of 6%. This increase significantly reduces the steam consumption in the dryer section, and every 1% increase in dryness can reduce the steam usage by about 5%-7%.

These data clearly show the importance of a 1% increase in dryness after pressing. Through further dehydration through mechanical squeezing, the structural properties of the paper sheet are optimized, including increasing density and stiffness, eliminating mesh marks, improving paper strength and smoothness, while reducing air permeability and permeability, thereby ensuring drying quality and reducing drying costs.

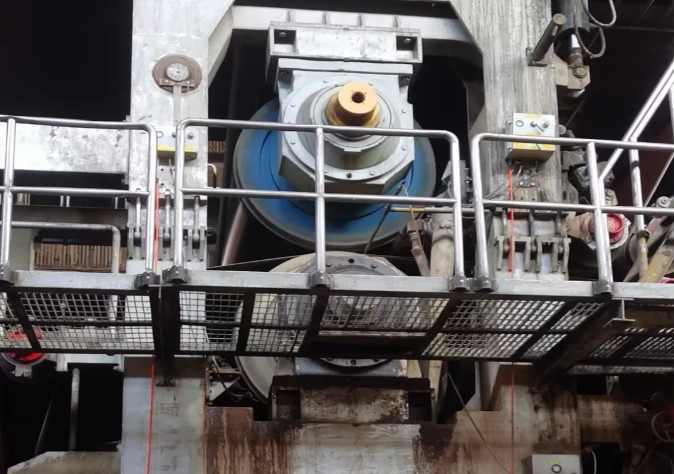

Common pressing devices and main variables

The pressing device is a key link that affects the dewatering effect of the paper machine. Different types of devices play a unique role for specific paper types and process requirements. The following are several common pressing devices:

- Ordinary pressing: basic device, suitable for a variety of paper types, but with low dehydration efficiency.

- Vacuum pressing: vacuum-assisted dehydration is used to improve dehydration efficiency, and is often used for paper types with high wet strength requirements.

- Groove pressing: special roller surface design increases the water removal path, suitable for scenarios with higher dehydration requirements.

- Blind hole pressing: blind holes are processed on the roller surface to effectively increase the dehydration volume and improve efficiency.

- Large roller diameter pressing: increasing the roller diameter to increase the nip width and residence time, suitable for high-speed paper machines.

- Shoe pressing: adopts a long nip design to significantly improve dehydration efficiency, and is the first choice for modern high-speed paper machines.

- Compound pressing: including three-roller two-press, four-roller three-press, five-roller three-press, etc., which can be flexibly configured according to the paper machine design.

The dewatering effect of the press section is affected by many variables, which need to be fine-tuned according to the operation of the paper machine:

Pressing load: directly determines the dewatering amount and paper density. Paper re-wetting: too high a moisture regain will reduce dewatering efficiency.

Nip width and residence time: wide nip and long residence time help to dewater more thoroughly.

Pressing form: different press forms are suitable for different paper grades and speed requirements.

Temperature and moisture content: higher temperature can reduce water viscosity, thereby improving dewatering efficiency.

Felt structure: efficient felt design can significantly enhance moisture transfer.

Paper quality: paper uniformity directly affects dewatering uniformity.

Vacuum degree: high vacuum helps to enhance dewatering.

Felt washing: keeping the felt clean is the key to ensuring long-term dewatering performance.

Classification of pollutants that affect felt dehydration

In the papermaking process, the use of raw materials and additives will cause various pollutants in the felt. These pollutants mainly come from fibers, fillers and chemical additives in production. According to their characteristics, pollutants can be divided into the following categories:

Alkaline soluble matter (biodegradable): including lignin, organic matter, starch and resin from additives, etc., which are easy to form sticky deposits on the felt.

Paper foam (granular dirt): composed of fine fiber particles, which are easy to block the pores of the felt and significantly reduce the dewatering performance.

Inorganic matter (granular dirt): such as titanium dioxide, calcium carbonate and porcelain clay, these inert minerals will form complexes with metal ions in hard water, causing blockage.

Extractable matter (oily dirt): including rosin, tar, asphalt, latex and ink, etc., which are soluble in organic solvents and deposited in the felt.

Resin and sticky matter (oily dirt): including residues of fillers, additives and synthetic polymers, which are usually further aggregated under high temperature or high pressure conditions and are difficult to remove.

In actual production, these pollutants are very likely to adhere to the felt, causing pore blockage, which directly affects the water filtration performance of the felt. According to statistics, 95% of the reasons for felt removal from the machine are due to contamination and blockage, and the remaining 5% are due to other loss reasons. Therefore, keeping the felt clean is crucial to ensure efficient operation and stable production of the paper machine.

Felt washing system

Mechanical washing During the operation of the paper machine, all press felts should be continuously mechanically washed. Mechanical washing usually uses high-pressure and low-pressure water spray pipes to loosen the dirt in the fabric and effectively remove it in combination with a vacuum suction box.

Chemical washing is a necessary supplementary measure for dirt that is difficult to remove mechanically. According to the nature of the felt contaminants, the appropriate chemical cleaning agent is selected and treated under specific pH conditions, and combined with the auxiliary effect of the vacuum box, the performance of the felt can be more thoroughly restored.

Classification and advantages of blanket cleaning

According to the type of dirt and cleaning requirements, commonly used cleaning agents can be divided into three categories: acidic, neutral and alkaline. The main ingredients are anionic surfactants, nonionic surfactants and dispersants.

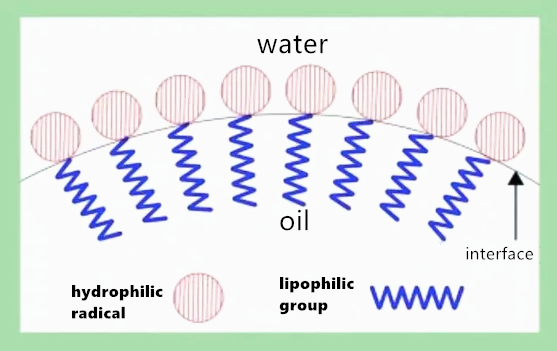

Surfactants are a class of compounds that can significantly reduce the surface tension or interfacial tension of liquids. Their molecular structure is amphiphilic, with a hydrophilic group at one end and a hydrophobic group at the other end.

Surfactants have a strong decontamination effect on oily dirt (extractables, resins and sticky substances) and granular dirt (paper foam, inorganic substances), and also have a certain ability to remove biodegradable dirt. Adding various enzyme preparations to biodegradable dirt can promote the rapid decomposition of biodegradable dirt (alkaline soluble substances).

The binding between dirt and the carpet matrix is diverse and complex, and can be combined through electrostatic action, chemical bonding or physical adsorption, and sometimes closely connected by a mutually dissolving and penetrating oily binding method. Due to the different binding methods of the matrix, the removal mechanism of solid dirt and oily dirt is also different.

For oily dirt, the so-called “rolling off mechanism” is adopted. That is, with the help of the interfacial activity of surfactants and the preferential wetting characteristics of solid surfaces, the interfacial properties of dirt/solution, matrix/solution, dirt/matrix and the aqueous solution itself are changed, so that the small contact angle gradually increases and develops towards the equilibrium contact angle, and finally the oil dirt shrinks and is removed. The larger the equilibrium contact angle, the easier it is to remove the dirt, and the more thorough the removal.

Granular dirt only contacts and adheres to the matrix through a few active sites. Surfactants mainly adsorb on the surface of solid particles and the matrix, reduce the adhesion between the particles and the matrix, and separate them from each other. When using anionic surfactants, the surface potential between the particles and the matrix can be increased to help remove dirt; non-ionic surfactants rely on spatial barriers to prevent the particles from re-depositing, thereby achieving a good decontamination effect.

The decontamination process is a reversible process, and the removed dirt may be re-deposited on the matrix.

A high-quality cleaning agent should have the ability to both separate the dirt from the matrix and prevent the dirt from re-depositing. There are many types of surfactants with strong cleaning and decontamination capabilities. Among them, the most commonly used and largest-volume ones are anionic varieties such as alkylbenzene sulfonates, alcohol ether sulfates and fatty acid soaps, as well as nonionic varieties such as alcohol ethers and alkylphenol ethers.

Anionic surfactants have significant effects on polar particle scales and polar oil scales; nonionic surfactants are more effective in removing non-polar dirt. Since the actual dirt is a collection of oil/particle scale, anionic and nonionic surfactants are often used in combination to achieve the best decontamination effect.

The specific addition location and dosage should be determined according to the degree of felt dirtiness and paper machine design process. Customers are often concerned about the cost-benefit ratio of per ton of paper processing, such as intuitive evaluations including: changes in the number of press stoppages, changes in downtime cleaning time, changes in vehicle speed and production capacity, changes in steam consumption in the drying section, etc., to find a cost balance point while meeting production needs.

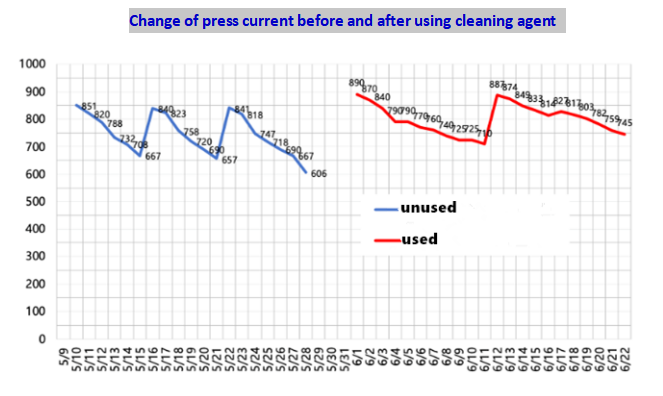

The following is the average current of the press section of a composite press paper machine before and after using a felt cloth cleaner:

Of course, it can also be evaluated by other methods. Common evaluation methods for felt cleaning effects include: changes in vacuum degree of vacuum suction box, changes in dehydration volume, changes in air permeability of felt, changes in color of felt, changes in gloss of felt, etc.

The main advantages of blanket cleaning include:

- Improve paper machine efficiency

- Reduce end breaks and downtime

- Increase machine speed

- Improve product quality

- Reduce steam consumption

- Keep vacuum box clean

- Improve economic benefits

Conclusion

Blanket cleaning is essential to maintain the dehydration performance of the blanket, extend its service life and optimize the operating conditions of the press section. Choosing the right cleaning agent and cleaning method can significantly improve production efficiency and paper quality, creating higher economic benefits for the company.