Introduction

During the entire paper machine operation process, the lubrication system is like the blood in human blood vessels, which is transported from various oil stations or pump stations to the required equipment parts.

The wider width, higher speed and greater load of the paper machine put forward higher requirements for the lubrication system.

Application experience of paper machine circulating oil

From pulping, to paper machine, to sewage treatment, different equipment working conditions have different requirements for lubricating oil. This time, we will share the oil used in the paper machine circulating system of the drying part (hereinafter referred to as paper machine circulating oil).

Most of the drying cylinders of modern paper machines use rolling bearings. When the drying cylinder heats up, thermal expansion will occur in both radial and axial directions. The drying cylinder bearings use a larger clearance and reserve the moving phase of the bearing on the operating side. In order to ensure the reliable working conditions and necessary cooling of the bearings, when the paper machine speed reaches more than 250m/min, the drying device adopts a circulating lubrication system. On high-speed paper machines, the circulating lubrication system also supplies oil to the gears and bearings of the idler drive, the calender roller and the paper reel cylinder bearings, the guide roller bearings, etc. The remaining rollers are generally lubricated with intermittent lubrication or grease.

As paper machines develop towards large-scale, wide-width, high-speed and automated directions, the working conditions of paper machines have become very harsh, and the temperature of the oil-using parts of their drying devices is as high as 110~132℃. In order to ensure the smooth operation of the paper machine drying device, when choosing lubricants, you must not choose internal combustion engine oil, hydraulic oil, gear oil, but should choose special circulating oil for paper machines. For paper machines with a speed of less than 1000m/min and a width of less than 6m, you can choose ashless mineral oil lubricants with a kinematic viscosity of 220mm2/s (40℃), while for paper machines with a speed greater than 1000m/min, you should choose ashless synthetic lubricants with a kinematic viscosity of 220mm2/s (40℃). Because these lubricants have good oxidation stability and low coking tendency, good oil-water separation, extreme pressure anti-wear and filterability.

Modern paper machines have high loads, high speeds, high temperatures, high water vapor humidity, and serious dust pollution. Therefore, the lubricating oil used is required to have suitable friction coefficients, extreme pressure resistance, wear resistance, oxidation resistance, oil-water separation and other properties.

Classification and composition of lubricating oil

Main categories of lubricants:

- Mineral lubricating oil

- Semi-synthetic lubricants

- Fully synthetic lubricant

At present, most common hydrogenated synthetic papermaking recycling oils are available on the market.

The composition of general lubricating oil includes

Base oil

Base oil is divided into: mineral base oil and synthetic base oil.

The quality and process formula of the base oil determine the comprehensive performance of the lubricating oil (regenerated oil will not be described in details).

Well-known brand base oils include NIOC from the Middle East, SK from South Korea, Nippon Oil from Japan, Formosa Petrochemical, etc.

Additives

Lubricating oil additives are oil-soluble compounds that can significantly improve the performance of the oil by adding a very small amount (a few percent to a few parts per million) to the oil.

Commonly used additives for paper machine circulating oil include the following:

1) Detergent and dispersant: It can play the role of acid neutralization, solubilization, washing and adsorption.

2) Antioxidant and preservative: During use, it can continuously neutralize the acidic substances generated by the oxidation of lubricating oil and prevent them from further oxidation. At the same time, by neutralizing this part of the acid, it prevents acidic substances from corroding metal parts.

3) Extreme pressure anti-wear agent: It is a special chemical additive that can react chemically with the metal surface to form a chemical reaction film, which can lubricate the metal surface, prevent scratches on the metal surface, and reduce friction and wear between metal parts.

4) Metal deactivator: Prevent or delay the rate of oxidation and deterioration of lubricating oil due to temperature, oxygen, light, etc. during use, and reduce the probability of acid, sludge and precipitation after oxidation.

Magnetic absorber Impurities and sludge on the magnetic absorber

Major international lubricant additive companies:

The Lubrizol Corporation, Infineum, Chevron, Afton Chemical, etc.

Main quality indicators of circulating oil

The main quality indicators of circulating oil are:

- Kinematic viscosity: a measure of the internal friction of a liquid when it flows under gravity.

- Viscosity index: indicates the degree to which the viscosity of a fluid changes with temperature. The higher the viscosity index, the less the viscosity of the fluid is affected by temperature, and the less sensitive the viscosity is to temperature.

- Pour point: the lowest temperature at which a test oil cooled under specified conditions begins to flow, expressed in °C. The higher the pour point, the worse the low-temperature fluidity of the oil; conversely, the lower the pour point, the better the low-temperature fluidity of the oil.

- Acid value: the number of milligrams of potassium hydroxide required to neutralize 1 gram of acidic substances in the oil is called the acid value, expressed in mgKOH/g.

- Oxidation stability: the ability of an oil to resist the action of air or oxygen that causes permanent changes in the properties of the oil is called the oxidation stability of the oil.

Paper machine circulating oil 150#, 220#, 320#, the commonly used specification 220# is mostly used.

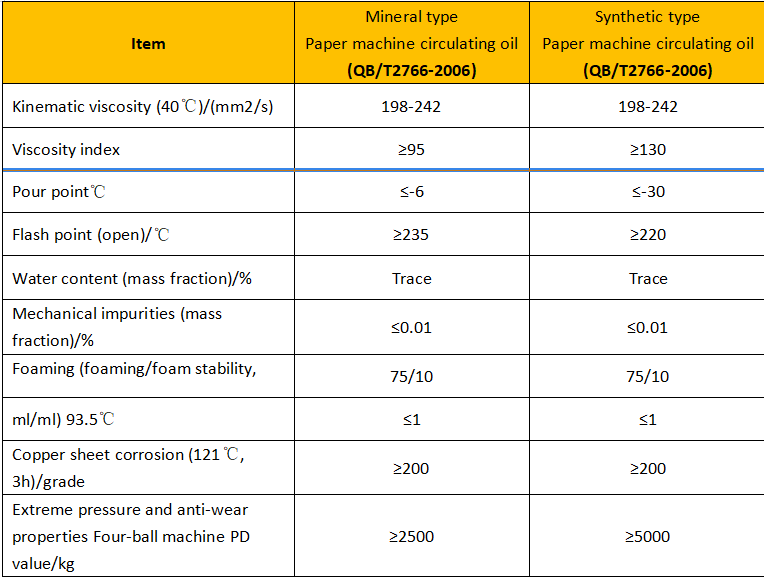

The quality indicators of mineral and synthetic paper machine circulating oils are as follows (taking viscosity grade 220# as an example):

Frequently Asked Questions

Here we have summarized some common questions about paper machine circulating oil that everyone is more concerned about:

Q1 Can paper machine circulating oils of different brands be mixed?

It is generally not recommended to mix paper machine circulating oils of different brands. In special cases, qualified units should make a mixing test before making a decision. Generally, similar products of similar quality or high quality mixed with low quality are used for equipment as low quality.

Q2 What should I do if water enters the circulating oil thin oil station?

Stop the machine immediately when a small amount of water enters. After the oil and water in the circulating oil of the thin oil station are separated, remove the bottom water and add new oil. Monitor the operation of the paper machine and take samples for analysis. When there is a lot of water, stop the machine immediately and replace the new oil to avoid emulsification of the circulating oil and cause wear on the equipment.

Here is some basic knowledge: when water enters the oil, it will combine together at the right temperature and concentration to form a dense monolayer, which will enclose the water. A large number of association bodies are evenly dispersed in the oil to form an oil-in-water emulsion. The emulsion with “oil” as the external phase and “water” as the internal phase is called an oil-in-water emulsion, expressed as W/O.

Q3 What should I do if the circulating oil temperature is high?

Check whether the reason for the high oil temperature is a cooler problem, or whether the circulating oil aging, carbonization, and coking produce impurities such as sludge that block the pipeline, and take oil samples for analysis and testing.

Q4 How to deal with high impurity content in circulating oil?

Take samples for analysis. If there are a small amount of impurities, they can be filtered online.

Q5 Which position is suitable for the liquid level of the dilute oil station?

It is better to have the liquid level of the dilute oil station level gauge in the middle and above.

Q6 How to determine the distribution position of the oil distributor?

Combined with the medium and appropriate position of the oil circuit position.

Conclusion

Synthetic paper machine circulating oil has excellent load-bearing capacity, thermal stability, oxidation stability and viscosity-temperature characteristics, good corrosion resistance, rust resistance, anti-foaming and demulsification properties. It can reduce the number of oil changes and reduce unplanned downtime. Compared with mineral oil lubricants, it can extend the oil change cycle by more than double.

Scientific use of oil and reasonable oil selection, with the purpose of reducing costs and increasing efficiency, will continuously safeguard safe production and stability.