Today let’s take a closer look at the basic components of a good paper.

Question: Which paper is the best?

Answer: Obviously, there is no standard answer to this question. A good paper is a paper that is completely suitable for its application.

To achieve this, you need to choose the right ingredients in the paper. So, today let’s take a look at the main components of paper.

Fibers

In addition to cellulose fibers from hardwood (hardwood pulp, or often called short fibers) or softwood (coniferous pulp, or often called long fibers), textile fibers (such as cotton, linen, hemp, ramie… but also synthetic fibers made from viscose, polyester, etc.) can be used to give paper specific properties such as strength, softness, chemical resistance, water absorption, etc.

Fibers

In addition to cellulose fibers from hardwood (hardwood pulp, or often called short fibers) or softwood (coniferous pulp, or often called long fibers), textile fibers (such as cotton, linen, hemp, ramie… but also synthetic fibers made from viscose, polyester, etc.) can be used to give paper specific properties such as strength, softness, chemical resistance, water absorption, etc.

Regarding the wood economy, here are some data from France, as shown below.

In France, 7 wood species occupy 80% of the entire French forest.

- Hardwood (2/3 of French forests): oak (50% of hardwood) + beech

- Softwood (1/3 of French forests): French Maritime Pine (Pinus pinaster, grown in southwestern France), Fir (Abies alba), Red Pine (Pinus silvestris) and Spruce (Picea excelsior).

France produces about 50 million cubic meters of wood per year. China is one of the main export markets for this wood (wood for construction and furniture). The paper industry uses 15% of this wood: 1/3 of it comes from sawmills (wood that cannot be used for construction or furniture: sawdust, tree trunk edges, etc.), and the other 2/3 comes directly from forests (mainly small trees).

Trees arriving at the pulp mill

A “good” paper is made from wood fibers that come from well-managed forests. Certification by FSC (Forest Stewardship Council), PEFC (Program for the Endorsement of Forest Certification), or other serious certification bodies is a good way to ensure that the fibers used to produce paper come from properly managed forests and that the owners of those forests are not destroying them.

The morphological characteristics of cellulose fibers include the following aspects:

Microscopic images of hardwood and softwood fibers

A. Fiber length

Long fibers are essential for improving paper strength. However, very long fibers may cause high flocculation, resulting in poor paper formation, poor uniformity, and reduced paper strength.

Fiber length affects paper formation, tear strength, tensile strength, and paper machine runnability and post-production use in paper processing.

B. Fiber width

Fiber width, more specifically, cell wall thickness (or cavity diameter): Fibers with thick cell walls can be refined at higher SEL (specific edge load), which is important to optimize fiber refining and avoid cutting fibers. For information about refining, please read this article:

C. Number of fibers per unit mass

The number of fibers per gram weight has a great impact on paper formation, opacity and softness, and roughness.

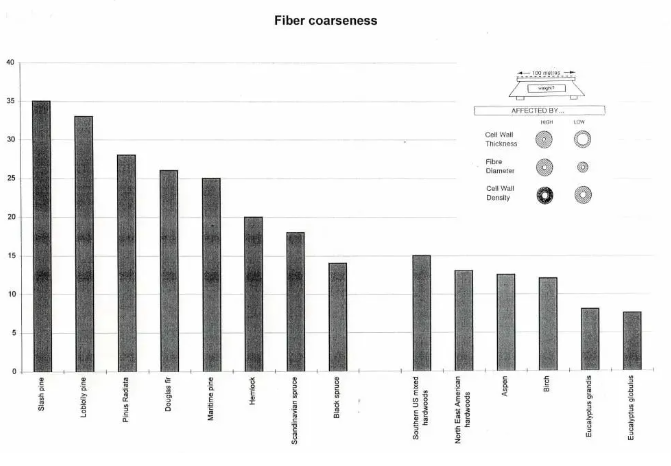

D. Coarseness

Coarseness (weight of 100 meters of fiber): affects smoothness or roughness, strength, volume, absorption, and required refining energy.

Fillers

What are the pros and cons of using mineral fillers in paper?

Advantages:

- Provides higher opacity, especially titanium dioxide (TiO2) and precipitated calcium carbonate (PCC)

- Better stability, insensitive to changes in humidity in the air (fillers are hydrogen bond breakers = better flatness of the paper)

- Improved printability

- Improved calendering suitability (higher smoothness can be achieved)

- Lower raw material costs (fillers are usually cheaper than cellulose fibers, except for TiO2)

Disadvantages:

- Reduced paper strength

- More dusting problems during printing

- Greater abrasiveness, except for talc and small amounts of PCC (precipitated calcium carbonate)

Brightness depends on the type of filler used. The brightness of bleached pulp is usually between 85 and 92 ISO. Here are the brightness of different types of fillers:

- Kaolin: 75 to 85 ISO

- Talc: 70 to 83 ISO (it is worth noting that in recent years, talc has been suspected of being a carcinogen to humans)

- Ground calcium carbonate: 80 to 85 ISO

- PCC: about 95 ISO

- TiO2: between 95-97 ISO

Starch

Starch is used to improve the physical properties of paper (same as the use of emulsions). Starch can be added in the wet part. In this case, the starch usually needs to be modified so that it can be fixed to the fibers (usually cationic starch is used). Unmodified starch can also be added to the paper surface in different ways (sizing, different coating equipment).

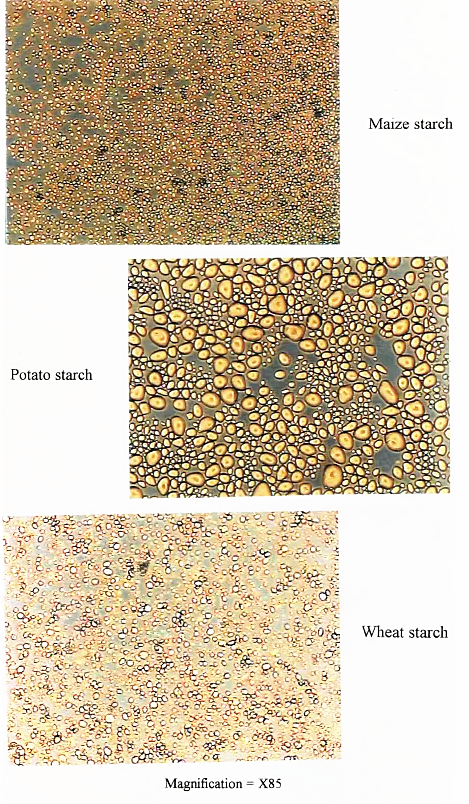

Below are some pictures of different types of starch used in paper manufacturing, here the starch granules are presented at the same magnification:

Microscope images of different types of starch at x85 magnification

When starch is added to the surface of paper, it can be used to improve the printability of paper and needs to be prepared in the following way:

- Starch particles are suspended in water;

- The temperature is increased to 60-70°C (steam injection);

- Amylase is added to the suspension to dissolve the starch;

- The enzyme reaction is stopped by increasing the temperature (>90°C) and/or adding chemicals.

Corrugated board manufacturers use large amounts of starch in the wet end and size press to improve the physical properties of the product, which is usually produced from secondary fibers.

Summary

Fibers, fillers and starch are by far the main components commonly found in paper, but they are by no means the only ones used in the papermaking process. In addition, dozens of chemicals are used in the production of paper for different purposes, such as:

- Improving the retention of fillers and fine fibers;

- Making the paper hydrophobic (paper size) or oleophobic (using fluorinated chemicals or silicone oils);

- Improving water filtration on the paper machine;

- Improving forming (especially when using synthetic fibers or very long fibers);

- Improving printability;

- Avoiding dusting of pigments and fillers (using latex alone or with starch);

- Increasing paper strength (using latex alone or with starch);

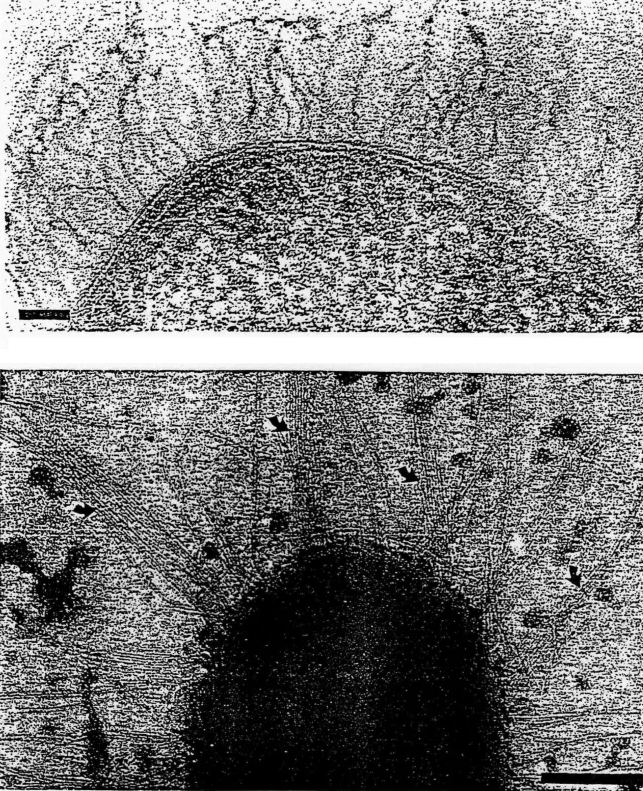

- Reducing clogging of the paper machine circulation system (using biocides) For example, a hair-like bacterium can be found in the papermaking circulation system (see the figure below). The “hairs” on the surface of the bacteria allow them to hook onto surfaces, thus producing slime.

Hair-like bacteria