Introduction

Tissue paper is often defined by its physical properties, in particular softness or feel, (low) density, bulk, thickness, flexibility or drape and its ability to absorb water. Tissue paper differs from flat grades in that the fibres are in a loosely bound, porous network rather than being tightly packed and bound. As a result, compared to conventional papers of the same basis weight, such as tracing paper or the coloured tissue found in some luxury packaging, tissue paper has a higher thickness and a lower density.

For most of the world’s tissue paper, the creping process is key to creating the low density and increased thickness. This article will focus on the traditional dry creping technology, which is currently used for most tissue production in the world, some aspects of which also apply to Through Air Dryer (TAD) technology.

Wrinkling mechanism

Definition

In order to understand wrinkling, we need to define some terms related to the subject.

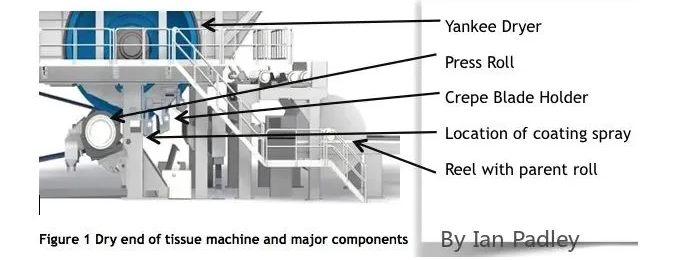

Yankee Cylinder: A steam-heated, rotating pressure vessel, typically 14 to 18 feet in diameter, slightly wider than the paper width, with a circumferential speed of about 30 m/s. It first creates back pressure against the press roll, then dries the paper by conduction heat (as the paper rests against it at 2/3 to 3/4 of its circumference), and finally provides a platform where creping occurs.

Creping blade: A blade fixed to the Yankee dryer, across the width of the Yankee dryer, at the creping location, forming part of the creping mechanical assembly.

Yankee coating: A mixture of naturally occurring pulp byproducts (e.g., lignin, hemicellulose) and applied chemicals that forms a thin, sticky coating on the Yankee surface, which aids in the transfer of paper from the rollers to the Yankee dryer and holds the paper in place during drying and creping.

The adhesion strength of the coating determines how closely the paper adheres to the Yankee dryer.

Creping zone:the area between the creping blade edge and the Yankee surface where creping occurs.

Blade holder:A mechanical device that holds the creping blade to the Yankee surface.

Creping Ratio: The speed difference between the Yankee (uncreped paper) and the reel (creped paper). Creping Ratio can be calculated in three different ways:

- Yankee speed/reel speed,

- (Yankee speed – reel speed)/Yankee speed,

- (Yankee speed – reel speed)/reel speed

(this is called “theoretical creping” and can be compared to MD stretch).

The parent roll:the full width roll obtained from the last unit reel of the tissue machine.

The process of destruction and combination

In the microseconds before creping, the tissue paper will reach its final dryness, typically 2-6% moisture content on the Yankee, with approximately 7 to 9 layers of fibers in a thin, tightly packed layer of fibers. The fibers are interconnected by hydrogen bonds (H-bonds).

One function of creping is to disrupt or break these hydrogen bonds, allowing the paper to expand in the Z direction, partially separating the 7 to 9 fiber layers. The energy to disrupt these bonds is transferred by the rotating Yankee, to which the paper is securely held by the Yankee coating. The moving paper strikes the stationary creping blade, energy transfer occurs, partial fiber-fiber H-bond failure and Yankee coating-fiber interface rupture.

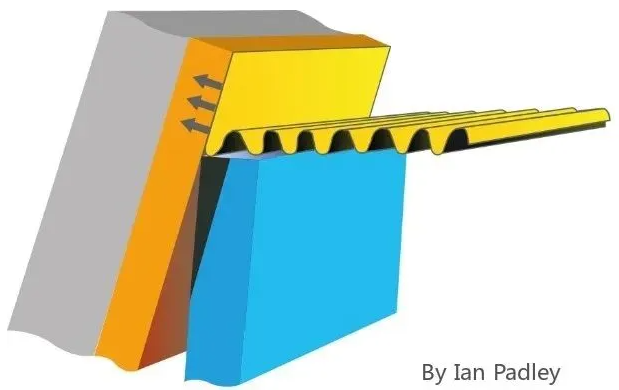

Creping Process

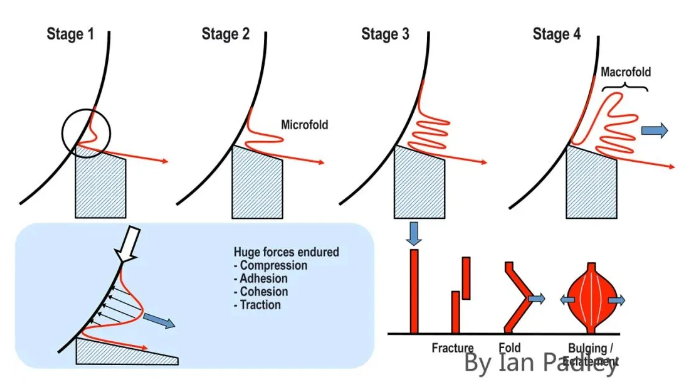

In addition to expanding the paper in the Z direction, some of the fibers will bend. Depending on the bond strength, the expanded and bent paper will be released from the Yankee surface a short distance (stage 1); the stronger the bond, the shorter this distance.

Thus, a small fold or wrinkle is formed before the paper is re-actuated by the scraper. Each wrinkle can be called a wrinkle bar and can be visually inspected using a low-power microscope. The number of wrinkles may be in the range of 20-40 per cm, which means that the wrinkle frequency is in the range of 50-120kHz.

Creping Rate

As the paper is wound onto the parent roll in the take-up section, the finished pleats are continually moved away from the crumpling zone. The creping process shortens the length of the paper while increasing its thickness. Therefore, the take-up section that winds the parent roll will run 15% to 25% slower than the Yankee.

Micro and macro creping

The thickness of the paper expands firstly by breaking hydrogen bonds in the Z direction and secondly by corrugation. The corrugation itself is not uniform and consists of alternating large wrinkles (macro wrinkles, stage 4) and many smaller wrinkles (micro wrinkles, stage 3). More micro wrinkles usually give a softer, more flexible paper.

However, at low magnification, micro wrinkles are difficult to see and we usually count only macro wrinkles. The corrugation can also be interrupted in the cross direction (CD corrugation), also called bubble corrugation. This is exactly what is needed for a toilet paper with a soft hand.

The main factors affecting creping

With a basic understanding of the wrinkle formation mechanism, let’s discuss the main factors that affect wrinkle formation and how they affect the final wrinkle characteristics and thus the paper properties of tissue paper.

Fiber Selection and Management

As mentioned above, paper undergoes two transformations, Z-direction hydrogen bond breaking and fiber bending. Therefore, some fibers will resist these processes better than others. Typically, toilet paper manufacturers use a mix of short (hardwood) and longer (softwood) fibers to achieve the final paper strength properties they desire.

Longer softwood fibers have good hydrogen bonding potential, adding strength and stiffness to the paper, but do not wrinkle easily. Softwood fibers with lower coarseness (measured as pulp coarseness index or PCI in mg/100m) are preferred, with NBSK pulp used in many premium products having a PCI of 13-15 mg/100m. Hardwood fibers are shorter, with a PCI of less than 10 mg/100m, and wrinkle well, but do not provide strength.

For kitchen paper, softness is not a critical point, so kitchen paper may contain 70% softwood, while facial tissue may contain less than 10% softwood, with 20% being more typical.

Furthermore, refining of the fiber is critical (softwood is preferred), whether mechanical or enzymatic, and in any case only gentle refining is required to minimize fiber cutting; over-refined paper will become stiff and lose bulk.

Yankee dryer coating

The Yankee coating is a very critical factor. While other authors have discussed the chemical considerations in detail, in this article we focus on the general properties.

The Yankee coating is a mixture of a polymer (which can be film-forming or thermosetting), usually some kind of polyamine, a release component, usually based on mineral or vegetable oils, and sometimes a modifier to adjust the film rheology.

These substances are sprayed onto the Yankee dryer as an aqueous solution at a concentration of about 1%, about 1 meter before the sheet is transferred to the Yankee dryer’s nip. During this 1 meter distance, the Yankee dryer will evaporate most of the water, and the sticky film will pick up the wet paper from the rollers. The polymer component will firmly hold the paper web during the drying process, ready to resist the creping pressure.

To understand how tissue manufacturers select and control these chemicals, we can classify coatings into three main types:

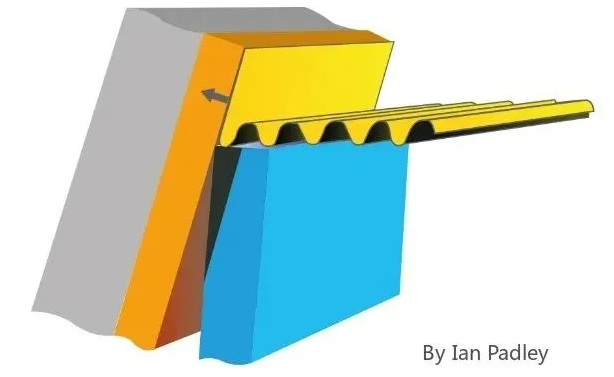

i.Soft and low-tack coating

Soft and low-tack coating with rough, fluffy folds

A soft, low-tack coating will produce a coarse, wrinkled paper with high wrinkle amplitude and low frequency. An adhesive layer breaks easily, resulting in a large, fluffy wrinkle structure, which is often used in the production of hand dry wipes.

ii.Hard and highly adhesive coating

High adhesion, hard coating and fine and smooth wrinkles

A highly tacky and hard coating will produce a very fine wrinkling effect with low amplitude and high frequency. The break span of the adhesive layer will be very small. This is usually suitable for producing facial tissue or handkerchiefs with a low grammage but a very smooth feel.

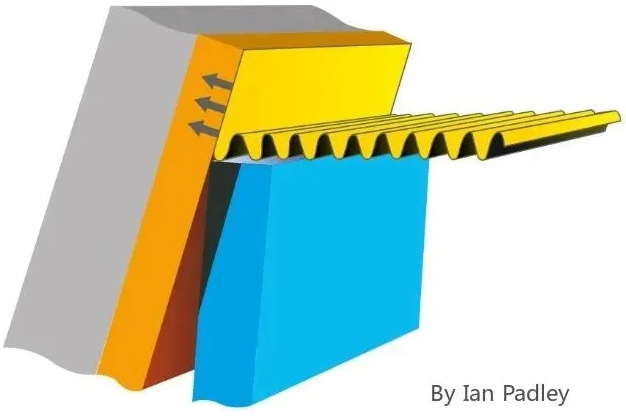

iii.Soft and highly adhesive coating

Soft and highly viscous coating with soft and heavy folds

A soft, highly tacky coating will produce a high crepe frequency and amplitude, and will be characterized by a high proportion of micro-crepes in the crepe structure. It is generally believed that the crepe blade penetrates deeper into the coating, which creates a more fluffy structure. This type of crepe is characteristic of soft, fluffy tissues, such as premium toilet tissue.

Paper drying

Increasing the temperature of the Yankee dryer will increase the adhesion of the coating to some extent and can improve the paper’s bulk and feel. Some ultra-premium tissues are made at very low moisture levels. However, excessive drying will also harden the coating, ultimately preventing the production of the fluffiest crepe paper. Therefore, it is generally believed that hood drying will generally be beneficial in achieving higher softness.

Geometry of the wrinkled zone

Geometry of the creping zone

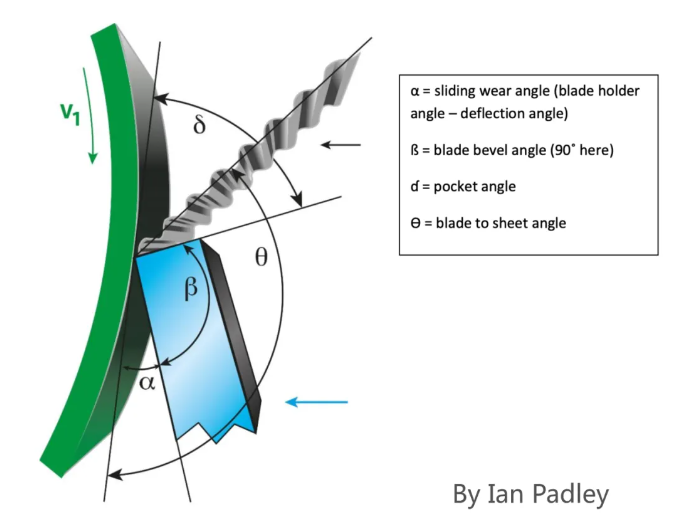

As shown in the figure above, the wrinkle zone angle parameter is another key factor. The important angle is the wrinkle angle δ, which is a combination of the blade chamfer angle β and the blade holder sliding wear angle (scraper angle) α. Because the blade may deflect, the blade free height or protrusion also affects this.

The blade holder sliding wear angle α is also affected by the deflection or bending of the blade, so the sliding wear angle α includes the actual blade holder angle (sometimes called the blade setting angle) minus the deflection amount. The final sliding wear angle is limited in two ways.

If the angle is too low (for example, less than 15° tangent to the Yankee surface), its ability to separate the paper is impaired and the paper may bypass or jam the blade, causing a paper break. If the angle is too high (much more than 20°), too much friction is applied to the Yankee, and Yankee wear or damage due to vibration marks may become a problem in the long term. Therefore, the holder angle is usually adjusted between 15.5° and 20°.

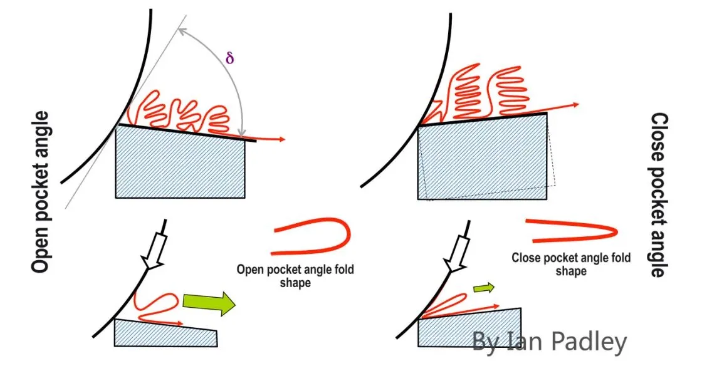

To achieve a larger wrinkle angle, the blade can be chamfered, with a chamfer angle of up to 60°. Larger crepe angles (greater than 90°) tend to produce lower bulk and tighter crepe (higher crepe frequency) structures, and are typically used for high softness tissue production.

In fact, as shown in Figure 7, the amplitude of the macro-wrinkles decreases with increasing crepe angle, and vice versa for closed crepe zones, which may result in higher bulk and lower feel.

The length of the blade extending from the tool holder (protrusion) will determine the fine-tuning of the crepe angle, as blade deflection can open the crepe angle up to 3°. However, high protrusion may also make the blade vibrate more and may cause bypassing, so a protrusion of 20-25mm is the most common tool holder setting.

Smaller wrinkle angles produce larger wrinkles

Crinkle Knife Material

The final factor is the creping blade material. The use of high performance (HP) creping blades, typically ceramic or carbide materials, is becoming more common because they offer certain advantages to tissue manufacturers looking to improve quality and productivity:

- Slower sliding wear rate. The sliding wear area of HP blades develops more slowly. The sliding wear pads of the blade reduce its specific loading pressure and thus its ability to handle paper and coatings. HP blades reduce the need to change blades (loss of production time).

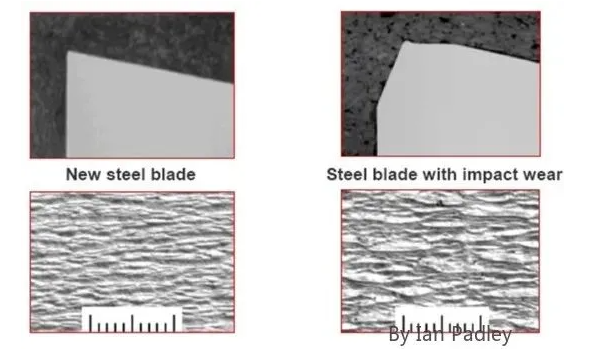

- Slower impact wear rate. The impact wear of a wrinkling blade produces rougher wrinkles, reduces the wrinkling angle and reduces paper softness. With HP blades, impact wear develops more slowly.

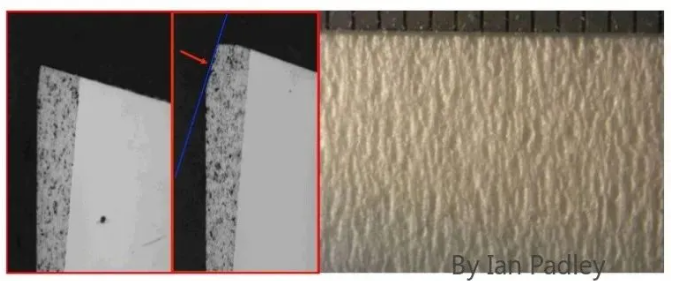

Effect of steel scraper wear on the wrinkle structure. On the left is a new steel scraper, on the right is a smoother surface of a steel scraper with impact wear

Smoother surface. The ceramic or carbide crinkling surface of an HP blade is very smooth compared to a steel blade of the same angle, which generally results in finer crinkling and a better feel. Bulk may be less, but this can usually be compensated for by operating a high performance (HP) blade at a smaller chamfer angle without compromising tissue softness.

Comparison of unused and used ceramic creping blades shows less impact and sliding wear, and the resulting smoother tissue surface.

Conclusion

In summary, we can find that wrinkling is a process of complex interaction of many factors. The basic mechanism of wrinkling is the destruction of hydrogen bonds between fibers, the distortion of fibers themselves, and the formation of micro- and macro-folds in the paper. For tissue paper manufacturers, the key factors to consider include fiber selection and management, the selection and control of Yankee coating, drying conditions, geometry of the wrinkling zone, and the choice of wrinkling blade material.