What is plant fiber for papermaking?

Plant fiber is a thick-walled tissue widely distributed in plants. Its cells are slender, pointed at both ends, with thick secondary walls and often pits on the walls. Fiber is a dead plant cell with a much larger length-to-width ratio.

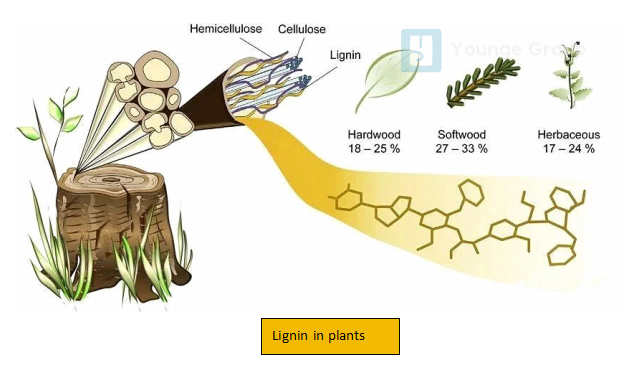

In fact, plant fiber is a long cell wall composed of cellulose (30-50%), hemicellulose (20-35%), lignin (15-30%), plus a small amount of extractable substances and ash.

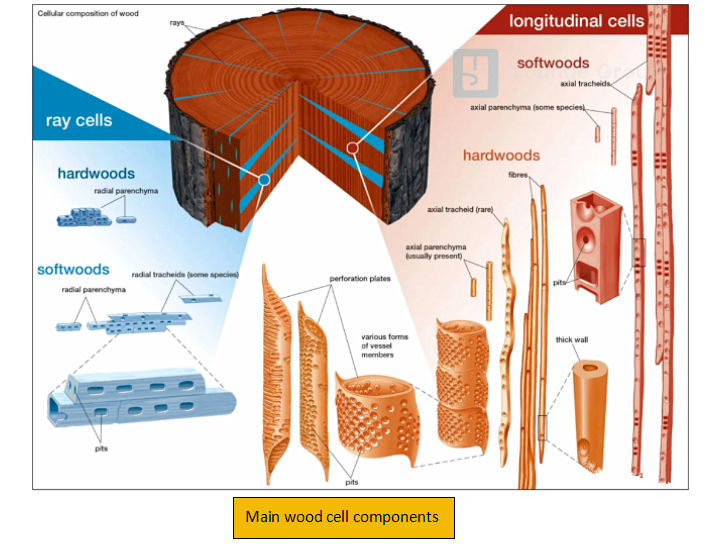

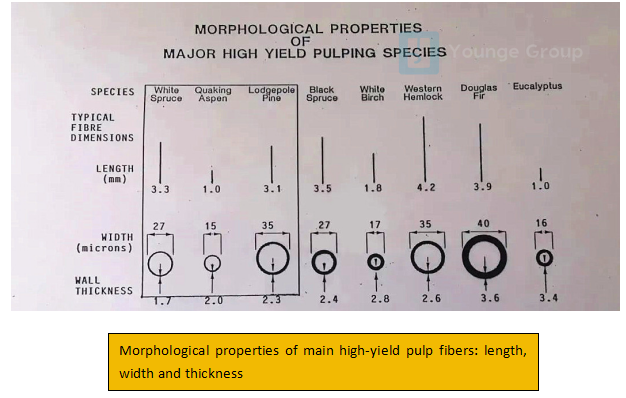

Wood fiber is the most widely used and main raw material in the field of pulp and paper making. According to different wood types, it is divided into softwood fiber (softwood) and hardwood fiber (hardwood). As shown in the figure below, it can be seen that in general, softwood fibers are more slender, while hardwood fibers are wider and shorter.

Chemical composition of fiber

The main chemical composition of fiber: cellulose, hemicellulose and lignin.

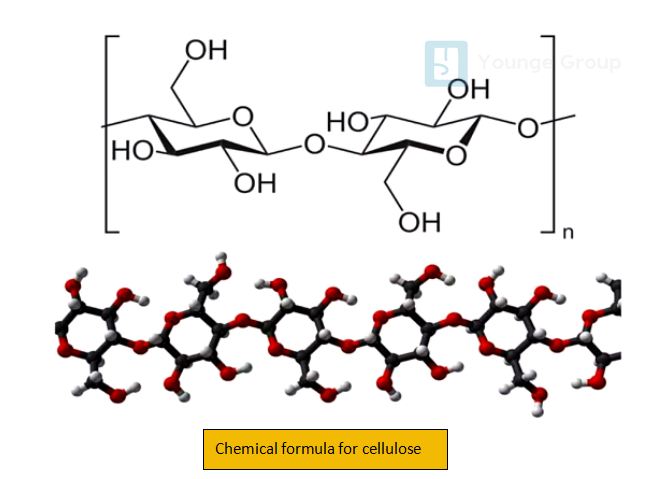

Cellulose is a macromolecular polysaccharide composed of glucose (the chemical formula of cellulose is shown in the figure below). It is the main structural component of plant cell walls and the most widely distributed and abundant polysaccharide in nature.

Plant stems and wood are supported by cellulose fibers distributed in a lignin matrix, where cellulose is like steel bars and lignin is like concrete. The purest natural form of cellulose is cotton, which contains more than 90% cellulose. In contrast, wood contains 30-50% cellulose. The high-value utilization of lignocellulose biomass has always been one of the hot research topics.

- Hemicellulose

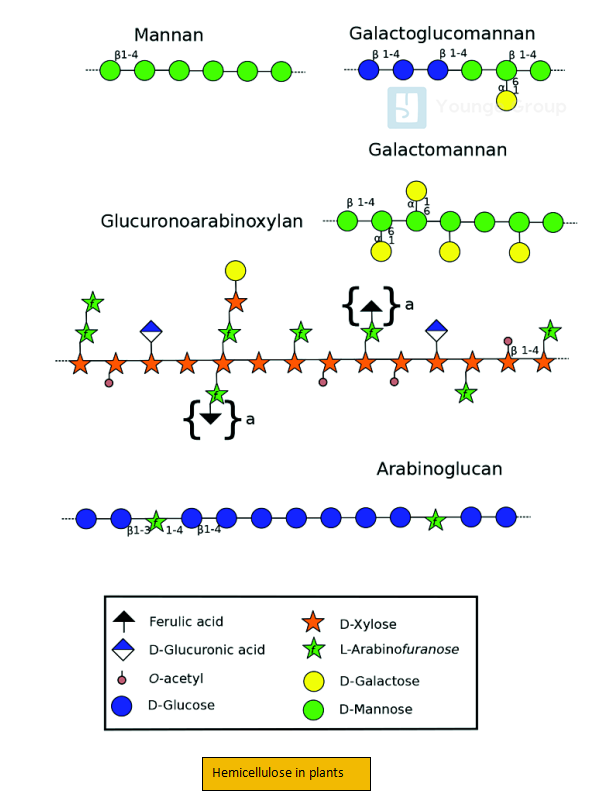

Hemicellulose is a type of heteropolysaccharide that exists together with cellulose in the cell walls of most plants. Hemicellulose has a random, non-crystalline structure; low strength; and is easily hydrolyzed under dilute acid and alkali conditions or under the action of a variety of hemicellulases, with a degree of polymerization of about 200.

Hemicellulose includes xylan, polygalactose-glucomannose, polyarabinose-galactose, glucomannan, and polyglucomannose, as shown in the figure below.

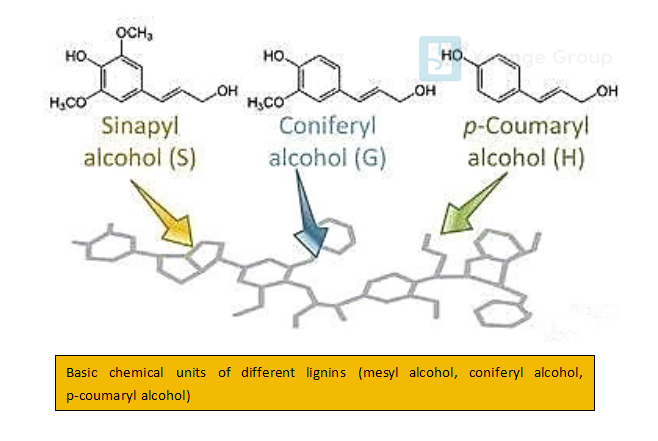

- Lignin

Lignin is a class of complex organic polymers that form important structural materials in the supporting tissues of vascular plants and some algae. Lignin is particularly important in the formation of cell walls, especially in wood and bark, because they impart rigidity and are not easily decayed and are hydrophobic. Chemically, lignin is a cross-linked phenolic polymer, belonging to a class of aromatic polymers (as shown in the figure below).

From wood to plant fiber raw materials for pulping and papermaking, complex mechanical and chemical treatments are required. The purpose of chemical pulping is to remove as much lignin, extractables and ash as possible and produce fibers made only of cellulose and hemicellulose. In the production of mechanical pulp, wood chips are ground with high-pressure steam and some chemical treatments, and some lignin is still retained in the fiber.

Fiber morphology

Fiber morphology mainly refers to the length, width, and thickness of the fiber cell wall. The length of wood fiber is usually between 1mm (hardwood) and 4mm (softwood), and the width is between 10um and 40um. The figure below introduces the fiber morphology of the main high-yield pulp.

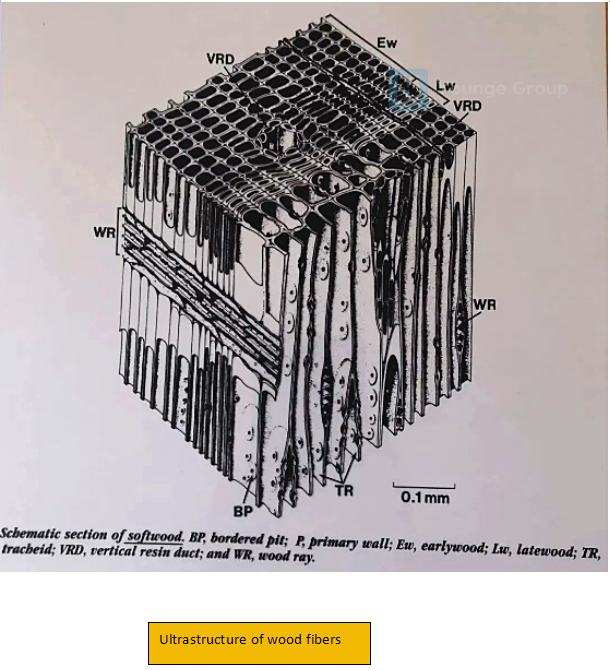

Ultrastructure of fiber

The reason why plant fiber can become the raw material of paper network structure is not determined by the chemical composition cellulose. For example, starch is also a macromolecular polysaccharide composed of glucose, but it cannot be used to make paper alone. Therefore, in-depth study of the ultrastructure of fiber is very necessary to understand the fiber produced by pulping and the basic principle of fiber making paper.

The figure below is the ultrastructure of wood fiber. We can see that wood produced in spring (Earlywood, Ew) grows fast and has thin cell walls, while wood produced in summer and autumn (Latewood, Lw) has fewer fibers and thicker cell walls (see the figure below). This difference in cell wall density brings about a difference in appearance color, which is used to calculate the annual rings of felled trees.

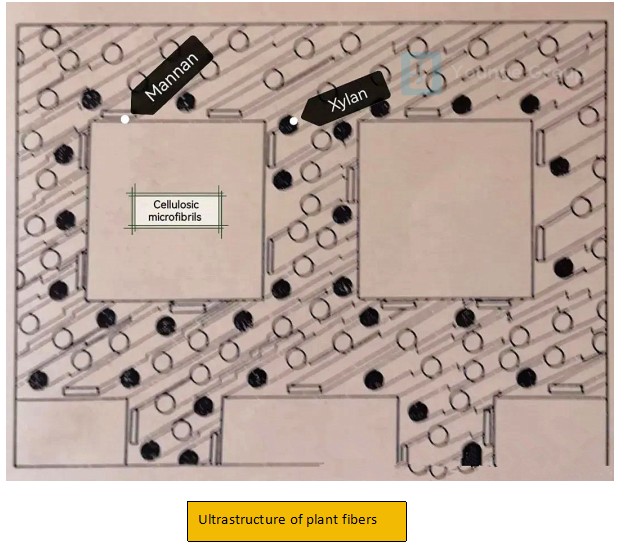

If we take a closer look at the plant fibers used for papermaking (see the figure below), we can see that the fiber cell wall is composed of cellulose microfibrils, with an average diameter of about 3.5um, containing about 40 single cellulose molecules. These microfibrils are surrounded by hemicelluloses, such as mannan and xylan, which are closely connected to lignin. These connections are broken during the pulping process, thereby removing the lignin. When forming the three-dimensional network structure of paper, hydrogen bonds are formed between the cellulose in the fibers, between cellulose and hemicellulose, and between hemicelluloses ( The Effect of Fiber Properties on the Tensile Strength of Paper), thus generating the strength of the paper.