From wood to fibers with certain flexibility and bonding strength, a series of complex mechanochemical steps are required. This is the pulping and bleaching process we mentioned earlier. Pulp that has undergone the pulping and bleaching process can be sold as commercial pulp on the market, or used as raw material in integrated pulp and paper mills.

However, the flexibility and bonding strength of these pulps are not enough to make so-called “paper”. At this time, it is necessary to mechanically treat the pulp in the preparation section of the paper mill to further improve the flexibility and bonding strength of the fibers. This step is the well-known “refining” or “beating”.

Concept of refining

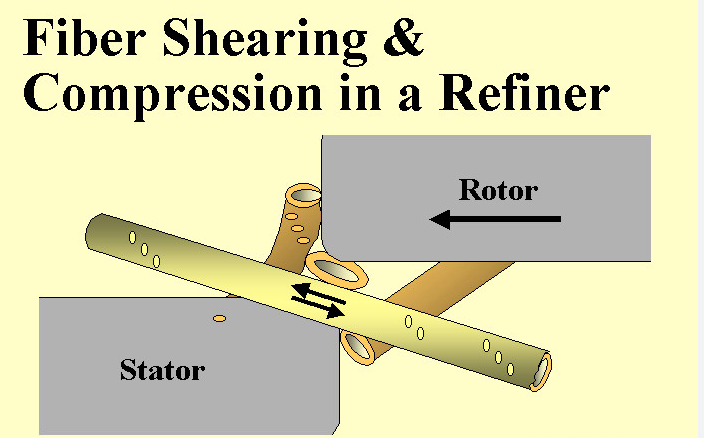

Refining refers to the shear force of the equipment on the paper fiber during the processing process.

The shear force can come from the mechanical action of the blade or grinding teeth of the refining equipment, or from the shear force generated by the velocity gradient and acceleration between the fiber and the fluid. During the refining process, the fiber suspension passes through the refining equipment continuously and is refined in the refining mechanism composed of the rotor knife roller flying knife (or rotating disk grinding teeth) and the fixed fixed knife (or fixed disk grinding teeth). Its characteristic is that the fiber is parallel to the blade (or grinding teeth) when passing through the refining mechanism.

Refining technology has the characteristics of continuous production, high efficiency, low energy consumption, and can adapt to the requirements of large-scale, high and medium concentration, multi-functionality and centralized automatic control. Therefore, it has made significant developments in technology and equipment and has become the dominant technology in the refining process.

The unrefined pulp sent from the pulping system generally contains many fiber bundles.

Because the fiber is thick and long, the surface is smooth, hard and elastic, the fiber specific surface area is small and lacks bonding performance. If the unrefined pulp is used directly for papermaking, it is difficult to obtain uniform distribution on the net, and the finished paper is loose and porous, the surface is rough and easy to fluff, the bonding strength is very low, the paper performance is poor, and it cannot meet the requirements of use.

Refining makes the pulp fibers subject to shear force. In addition to kneading and loosening the pulp to decompose the fiber bundles into single fibers, the fiber cells first produce displacement and deformation, the P layer and S layer of the cell wall are partially broken and fiber fragments are produced, and the fibers are cut and twisted, curled, compressed and stretched. While the P layer and S₁ layer are partially broken, the fibers absorb water and swell and become fine fibers. The fiber surface is separated into many fine fibers, the ends of the fibers are broomed, the specific surface area of the fibers increases, the surface becomes rough, and the cohesion between the layers decreases. The fibers become softer and more plastic, and the water filtration performance of the overall paper material decreases.

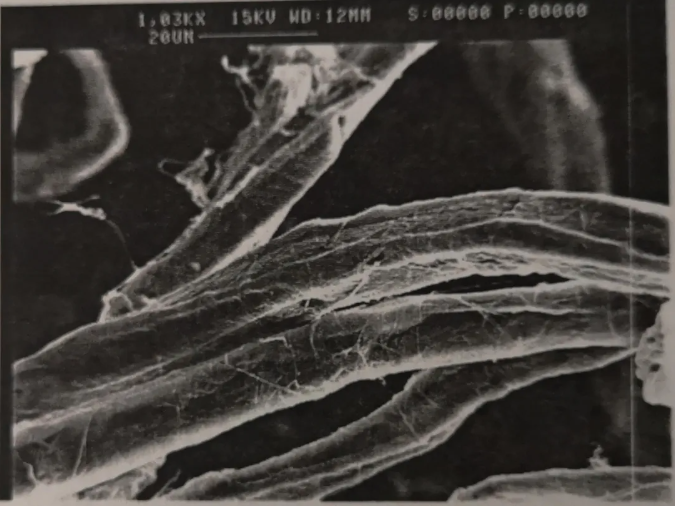

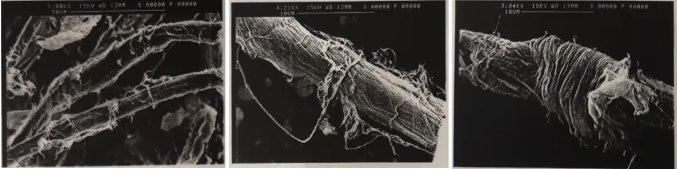

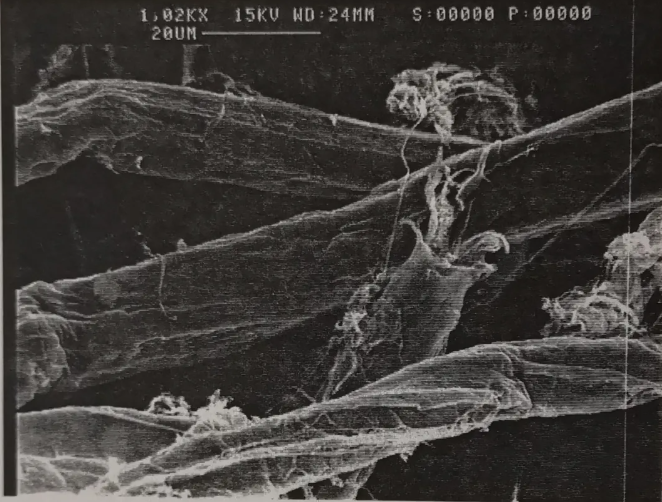

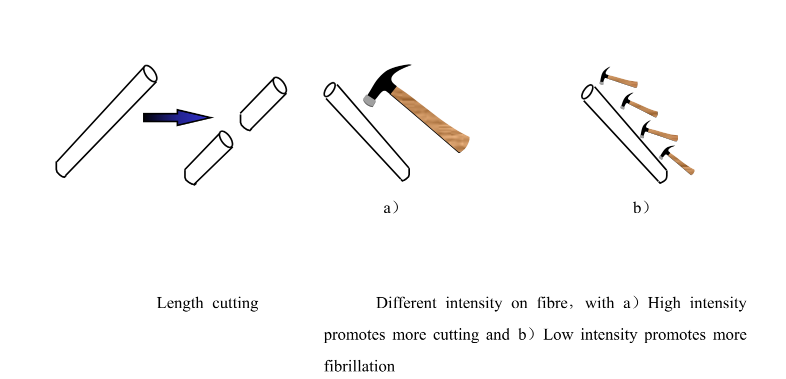

The effect of fiber treatment is shown in Figure 1-1.

The effect of fiber treatment

SEM image of unrefined fiber

SEM image of lightly refined fibers

SEM image of heavily refined fibers

Note:

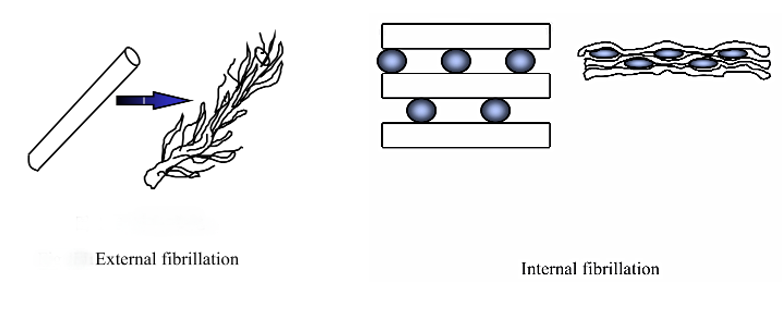

Fibrillation :After physical and chemical beating, the fibers will become fluffy, torn, and split. Brooming is divided into external and internal bedding.

Fibrillation

Cutting: Cutting refers to the phenomenon of fiber breaking transversely.

Cutting is mainly the result of fiber breaking transversely due to the shear force of the pulping equipment and the friction between the fibers. Fiber cutting has a certain relationship with swelling. After the fiber absorbs water and swells, it has good flexibility and is not easy to cut. On the contrary, if the fiber is poorly swollen and stiff, it is easy to cut. After the fiber is cut, the fracture increases, which is conducive to the penetration of water, and can promote the swelling of the fiber, which is conducive to the fiber splitting and fibrillation. After the long fiber is properly cut, the uniformity and smoothness of the paper can be improved, but excessive cutting will reduce the strength of the paper, especially the tear resistance. For short fiber pulps such as hardwood and grass fibers, the fiber length should be retained, and excessive cutting is not desired.

fiber cutting

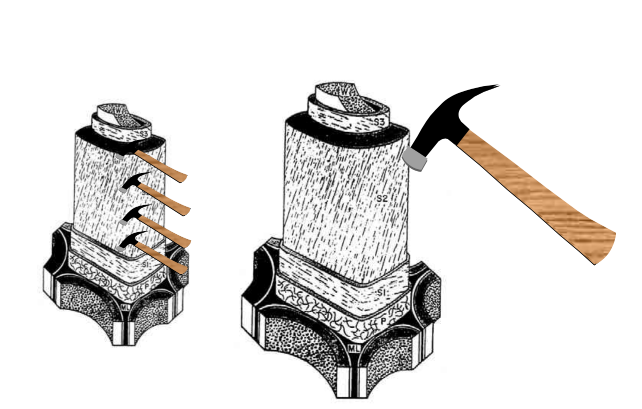

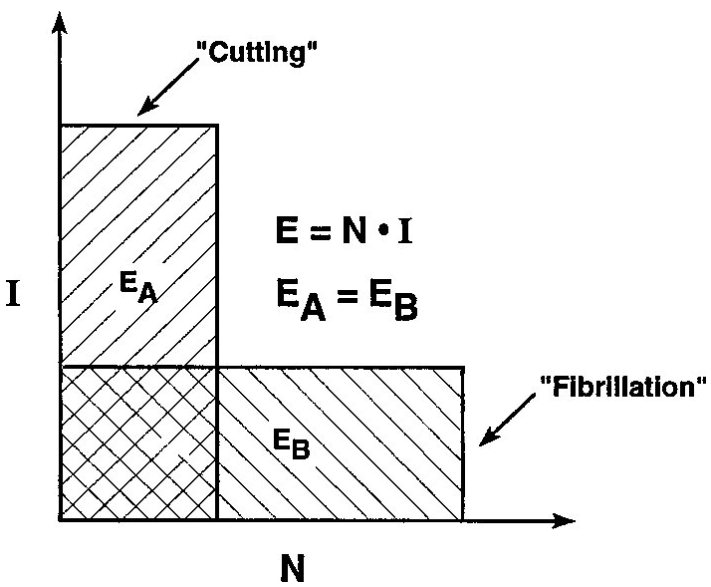

Refining intensity: Refining intensity e is the distribution of refining energy.

Illustration of Specific Refining Energy as the product of number and intensity of impacts on pulp

Low-intensity refining means that the force frequency of the grinding teeth on the fiber is high and the power is low, which is conducive to the internal and external fiber splitting;

High-intensity refining means that the force frequency of the grinding teeth on the fiber is low and the power is high, which is conducive to the cutting of the fiber.

It is affected by the number of grinding teeth and the dwelling time of the grinding disc. Changing the structure and speed of the grinding disc affects both the number of grinding teeth and the dwelling time.

Therefore, refining intensity is an important factor affecting the fiber structure.

Fibrillation: including external fibrillation and internal fibrillation.

External fibrillation refers to the longitudinal splitting of the fiber, the fiber surface fibrillation and fluffing, like fluff attached to the fiber surface. This surface microfibrillation makes the fiber loose and separates a large number of fine fibers, microfibers, and microfibers, thereby greatly increasing the external specific surface area of the fiber and promoting the combination of hydrogen bonds.

Internal fibrillation of fibers refers to the sliding between the secondary wall and the concentric layer after the fibers swell, which reduces the rigidity of the fibers, increases the plasticity, and makes the fibers soft and plastic. Both external and internal fibrillation of fibers are beneficial to fiber bonding and improve the strength, tightness and uniformity of the finished paper. It has a great impact on the properties of paper and is one of the important functions of pulping.

Classification of pulping concentration

Classification

The concentration of pulp has a great influence on the pulping quality. With the development of pulping technology, pulping concentration can be divided into low-concentration pulping, medium-concentration pulping and high-concentration pulping.

It is generally acknowledged:

- below 10% is called low-concentration pulping,

- 10%~20% is called medium-concentration pulping,

- 20%~30% is called high-concentration pulping.

Comparison

- Low-concentration refining

The main effects of low-concentration refining on fibers are longitudinal fibrillation and transverse cutting. Longitudinal fibrillation requires displacement and deformation of cell walls, breaking of primary and secondary walls, water absorption and swelling, and fibrillation. These processes are carried out alternately in refining, which greatly increases the surface area of fibers and the number of free shuttle groups, increases hydrogen bonding, and thus improves the physical strength of paper. However, the pulp contains a large number of epidermal cell communities, especially reed pulp and straw pulp, which are easy to “shed” and paste the plate during printing. Transverse cutting can improve the uniformity and smoothness of paper, but reduces the strength, especially the tear length and tear strength. Papermakers have repeatedly explored the cooking method, time, medication, the weight of the knife in refining, the sequence of procedures, temperature, equipment type, blade material, refining concentration, and the addition of additives in their long-term work, so as to make the best use of their strengths and avoid their weaknesses. At present, a more ideal method has been found from the perspective of refining concentration.

When the pulp concentration is below 10% and the equipment allows, the pulping concentration can be appropriately increased, and the pulp fibers entering the rotating disk and the fixed disk or between the flying knife and the bottom knife will increase, and the pressure shared by each fiber will be reduced accordingly, thereby reducing the fiber cutting effect, promoting the squeezing and kneading effect between the fibers, and being beneficial to the dispersion, swelling and fine fiberization of the fibers. Therefore, increasing the pulping concentration is suitable for beating sticky pulp, and conversely reducing the pulping concentration is beneficial to fiber cutting and suitable for free pulping.

When the pulping concentration is increased, the pulping degree is improved under the same pulping pressure and throughput, indicating that it is beneficial to the dispersion, swelling and fine fiberization of the fibers. In the same pulp, when the pulping concentration is increased, the fiber brooming rate increases, and the wet weight of the fiber and the average fiber length reduction rate decrease, that is, the fiber is cut less, while the output increases and the power consumption decreases.

The size of the pulping concentration is determined by the paper type, the pulping method and the performance of the pulping equipment. The pulping concentration of sticky pulp is 6% to 8%. The pulping concentration of the free pulp is 3% to 5%.

The improvement of pulping concentration is often limited by the pulping equipment. When pulping in the traditional low-concentration pulping equipment, such as the double-disc pulping machine widely used in paper mills, the teeth of the two grinding discs must be close to each other to realize the direct pulping effect of the grinding teeth on the fiber, causing the change of fiber morphology, and at the same time, it is inevitable to produce excessive cutting of the fiber. When operating at a higher concentration, the pulp flow will be poor or even blocked due to structural limitations. For example, the pulping concentration of the old pulping machine cannot be too high, otherwise the pulp circulation is not good, generally about 5% to 6%. The new type of pulping machine has a great improvement in structure, and the pulping concentration can be increased to 8% or even 10%. Continuous pulping is limited by the amount of pulp inlet, and it is difficult to increase the concentration. The general pulping concentration of the pulping machine is 3% to 4%, while the concentration of the high-speed pulping machine can reach 5% to 6%. Since increasing the pulping concentration has benefits, the pulping concentration should be increased as much as possible under conditions permitted by the equipment and based on the quality requirements of the paper type being produced.

- Medium-consistency refining

Concentration is an important parameter in the refining process. It directly affects the energy consumption, water consumption and refining effect of refining. A large number of scientific experiments and production practices have proved that increasing the refining concentration is conducive to forming a thicker fiber cushion layer on the tooth edge and tooth surface of the grinding disc, thereby reducing the cutting effect and enhancing the energy transfer between pulp fibers.

In the case of low concentration (3%-5%), the refining effect mainly relies on the direct action of the knife grain on the two relatively moving parts (grinding discs) to process the fibers. Due to the lubrication effect of a large amount of dilution water between the fibers, the friction probability between the fibers is greatly reduced. At this time, it is mainly the effect of the grinding teeth on the fibers, which leads to severe cutting of the fibers, and it is difficult to transfer energy between the fibers, resulting in difficulty in developing fiber strength.

As the pulping concentration increases, the moisture between the fibers decreases, and the contact and interweaving probability between the fibers increases, thereby increasing the friction between the fibers, so that the fibers between the grinding discs can be fully separated, fluffed, broomed and finely fiberized, accompanied by twisting and compression, which improves the flexibility of the pulp fibers and increases the bonding force between the fibers.

When refining at a higher concentration, the gap between the grinding discs is larger, and the local contact between the grinding discs can be weakened or even completely avoided, so that the fibers are protected from excessive cutting and grinding into powder.

Therefore, the pulp obtained by medium-consistency refining has less increase in fine fiber components and can better maintain the length of the original pulp fibers. At the same time, the fibers also have a higher shrinkage capacity. These characteristics of medium-consistency refining have opened up new ways to use short fiber pulp to produce high-strength pulp, thereby potentially increasing the use value of short fiber raw materials.

However, there is a limit to the increase in concentration. This is because when the concentration is too high, the water is insufficient and has no or little lubrication effect. The fiber cannot be fully swollen, and the pulping is difficult. It may cause the fiber to be re-grinded in the grinding area, resulting in excessive cutting. As a result, it not only affects the pulping quality, but also increases energy consumption.

From our experiments, it is feasible to carry out medium-consistency pulping at a concentration of 6%-15%. Among them, although medium-consistency (10%-20%) pulping of wood pulp helps to improve the strength of paper, the effect is not significant, and the power consumption is high, so it has not been applied in industry.

However, laboratory research on medium-consistency pulping of straw pulp has been carried out in China, and good results have been achieved. The research shows that the best effect is achieved when the concentration is 16%.

Its pulping characteristics are very different from those of straw pulp low-concentration pulping and wood pulp medium-high concentration pulping. Its main advantages are briefly described as follows:

- In medium-concentration pulping of straw pulp, the length of the fiber is reduced very little, and the S₁ layer of the fiber can be broken, so that the fiber can obtain good internal and external fine fiberization, but the fiber bonding force and the strength of the finished paper are greatly improved. For example, compared with straw pulp low-concentration (6%) pulping, the bursting resistance is increased by about 2.6 times, the breaking length and tightness are increased by about 20% compared with low-concentration pulping, but the tearing strength is 6% to 9% lower than that of low-concentration pulping, and the reason is not clear enough.

- High and low-concentration pulping of wood pulp achieves better strength development on the basis of increasing energy consumption, while medium-concentration pulping of straw pulp has high pulping efficiency and low energy consumption, and can achieve strength development while saving energy.

- In medium-concentration pulping of straw pulp, the paper sheet has a higher breaking length and elongation, which can effectively improve the toughness of the finished paper.

- Medium-consistency refining of straw pulp increases the softness of the fiber, reduces fiber fragments and short fibers, greatly increases the folding resistance, and can improve the brittleness of the paper sheet.

- Under the same strength, medium-consistency refining has a lower refining degree and a higher water retention value than low-consistency refining, and the finished pulp has better water filtration and wet strength. Therefore, it is beneficial to shorten the refining time, increase the copying speed, reduce the proportion of long fibers and improve the quality of straw pulp.

- Medium-low-consistency refining of straw pulp can also be done by medium-low-consistency two-stage refining of straw pulp, which can further reduce the refining energy consumption, and obtain better strength and tightness, greatly improve the burst resistance, tear length and folding resistance, and the tear resistance of the finished paper is equal to or slightly higher than that of medium-consistency refining. In short, the research results show that medium-consistency refining of straw pulp has many advantages and is of great significance to the utilization and development of straw pulp.

In the medium-consistency refining equipment, due to the particularity of the structure, pulp with a concentration of 6% to 15% is allowed to pass through the grinding area and the grinding chamber. At this time, the density of the fibers in the fiber mesh between the grinding discs is high, and the change of fiber morphology depends on the intense friction between the fibers, which causes a series of changes in the fibers, such as extrusion, crushing, cell wall rupture, splitting, fluffing, and fibrillation. The probability of fiber morphology change caused by the direct action of the grinding teeth is greatly reduced. As a result, the average length of the fibers is longer, the effect of fiber splitting is stronger, the fibers are less cut, and there are fewer fine fibers. This change in fiber morphology caused by intense friction between fibers is called “internal friction effect between fibers”.

- High-concentration refining

Principle of low-concentration refining: During low-concentration refining, the blade directly acts on the fiber.

The main difference between high-concentration refining and low-concentration refining is that high-concentration refining relies on the mutual friction between fibers for refining.

During low-concentration refining, due to the large amount of water between the fibers, the distance between the fibers is increased, and it acts as a lubricant, so that the friction and extrusion between the fibers are very small, which is not enough to affect the fiber properties. Therefore, low-concentration refining mainly relies on the blade to directly impact, shear, crush and rub the fibers. Therefore, low-concentration refining requires that the gap between the grinding discs must maintain the thickness of a single fiber to make the fibers strongly affected.

However, due to the processing and installation of the refining equipment, or the uneven wear during the use of the grinding disc, it is impossible for the gap between the grinding discs to be completely consistent. When the gap is too small, the fibers will be strongly crushed and cut. When the gap is too large, the fibers cannot receive the necessary refining treatment. Therefore, the uniformity of low-concentration refining is poor, and more cutting occurs.

High-concentration pulping, due to the high concentration of pulp and the large gap between the grinding discs, high-concentration pulping relies on the mutual friction, extrusion, kneading, and twisting of pulp fibers between the grinding discs to refine, and at the same time generates a large amount of friction heat.

Soften the pulp, which is conducive to the dissociation of fibers. During the high-concentration pulping process, the fiber length does not decrease much, the short fibers and fine fiber fragments are reduced, the beating degree does not increase quickly, and the water filtration performance is good.

The fiber morphology is also significantly different from low-concentration pulping. The fibers in low-concentration pulping are more longitudinally crushed and twisted, rather than the fibers in high-concentration pulping that are wide-banded.

The impact of high-concentration pulping on pulping quality and energy consumption From the above analysis, it can be seen that high-concentration pulping mainly relies on the mutual friction of pulp fibers between the grinding discs to refine, avoiding excessive crushing and cutting of fibers, and the fiber length does not change much. The degree of fine fiberization is high, the swelling is good, the paper strength is significantly improved, and the epidermal cell community is effectively removed, solving the problem of hair loss and fuzzy plates.

Moreover, high-concentration pulping does not rely on the grinding disc itself for pulping, which can increase the gap of the grinding disc and avoid the disadvantage of uneven low-concentration pulping.

The fibers of high-concentration pulping are mostly twisted and curled, with good shrinkage performance. The paper is strong and tough, and can greatly improve the shrinkage rate and toughness of the paper. This is more important for cement paper bags, cigarette paper, high-speed rotary printing paper and other paper types that require high toughness.

However, for long-fiber pulp, high-concentration pulping cannot be sufficiently cut, the pulp is easy to aggregate, and the fiber sedimentation speed is relatively fast, which is not easy to ensure the uniformity of the paper. In addition, high-concentration pulping consumes a lot of power.

In actual production, the two-stage pulping method is often used, that is, after high-concentration pulping, low-concentration pulping is used.

The two-stage pulping machine can reflect the advantages of high-concentration pulping, and can also achieve low-concentration uniformity, improve paper uniformity, and save power consumption.

In addition to the fact that the two-stage refining has little effect on the tensile strength and tear resistance of the paper, the paper’s burst resistance, tear length, elongation, toughness, and rupture work are greatly improved.

In the high-concentration refining process, due to the variety of unrefined pulps and the existence of many objective and subjective disturbances, these factors will affect the pulping quality and effect. Therefore, it is necessary to automatically control and optimize the high-concentration refining process. To achieve the automatic control and optimization design of the high-concentration refining process, the first problem that must be solved is to establish a mathematical model of the high-concentration refining process to provide a certain theoretical basis for it.

Pulp refiner category

According to the structure, it can be divided into three types: single-disc refiner/mill, double-disc refiner/mill, and triple-disc refiner/mill.

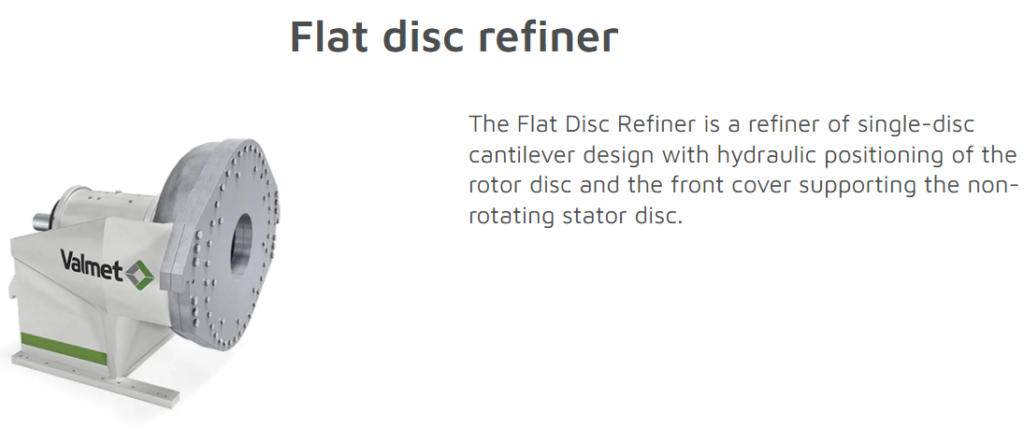

- Single-disc refiner

The single disc refiner consists of a fixed disc and a moving disc. A motor drives the moving disc on the shaft to rotate for pulping. The wood chips are fed into the refiner by a spiral belt around the main shaft.

Flat Disc Refiner /single-disc /cantilever design

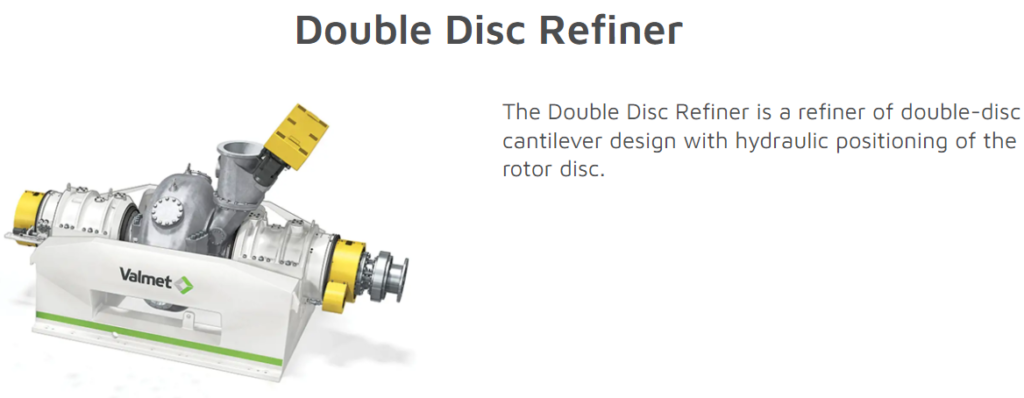

- Double- disc refiner

The double disc refiner consists of two moving discs with opposite rotations. Each disc is driven by a motor and fed into the refiner via a double spiral belt.

Double Disc Refiner/ double-disc /cantilever design

- Triple-disc refiner

The triple-disc mill consists of two fixed discs and a moving disc in the middle. The moving disc has two tooth surfaces on both sides, which form two refining chambers with the two fixed discs.

- Conical Refiner

In order to overcome the problems caused by large diameter grinding discs, Sunds Defibrator (Velmet) developed the concept of conical zone, which can increase the area of the grinding disc for refining.

The structure of waste paper refiner is very similar to that of wood chip refiner. However, since it does not need to overcome the bonding energy of large fiber spacing in wood chips, the power required per unit material is much less than that of wood chip refiner.

The main working parts of the waste paper pulping machine are also the fixed plate and the rotating plate. The concentration of the pulp entering the pulping machine is about 6-12%. Due to the low working concentration, the pulp inlet does not need a spiral feeder, but is directly connected to the pulp delivery pipeline. The pulp enters the pulping area at the center of the fixed plate and flows out to the surrounding areas.

Metso’s Opti Finer refiner uses a large conical disc for the stator and rotor. The conical disc increases the disc pulp area and greatly improves the working efficiency.

Steps of refining

Beating and/or refining is usually completed in two steps:

The first step is pre-refining, which is also the main refining process, and consumes 80% to 90% of the total refining energy.

The second step is refining before the headbox (Tickler refining, or headbox refining), where the refining is a second refining before the pulp goes on the net to quickly adjust the final refining degree of the pulp.

In addition to these two steps, an enzyme treatment step can be added before refining or between pre-refining and refining before the headbox. The main biological enzymes used in enzyme treatment are cellulase, xylanase, or a mixture of the two.

Evaluation of refining

Generally, there are two parameters to evaluate the degree of refining:

- The total energy consumed by pulp during the refining process, expressed in KWh/T pulp. All paper mills are very concerned about this indicator because energy consumption is directly related to costs.

- How the energy is applied to the fiber, that is, the degree of action of refining on the fiber, the degree of cutting or fiberization of the fiber by refining. Under the same energy consumption (KWh/T), different refining modes can produce different fiber morphology effects, thus affecting the characteristics of the paper.

There are three different methods for evaluating the intensity of refining:

- Specific Edge Load (SEL), in J/m: This is the most common and traditional method. The characteristic of this method is that it mainly considers the effect of the number of refiners.

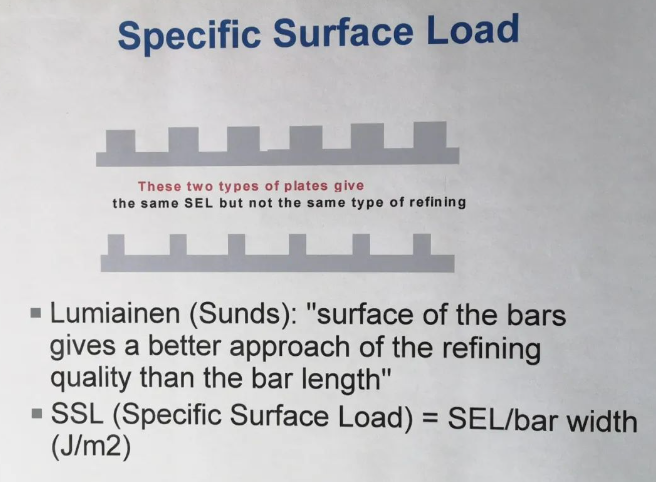

- Specific Surface Load (SSL), in J/m²: This is the method used by Sunds. This method is less common, but in fact more advanced, because it considers the effect of both the number of refiners and the width of the refiners.

- Evaluating the number of refining actions on the fiber and the energy of each refining action (in µJ/action): This method was proposed by Canadian researcher Richard Kerekes and is sometimes called the C-factor method. The intensity of the refining action depends on the geometry of the refiner.

How to control refining

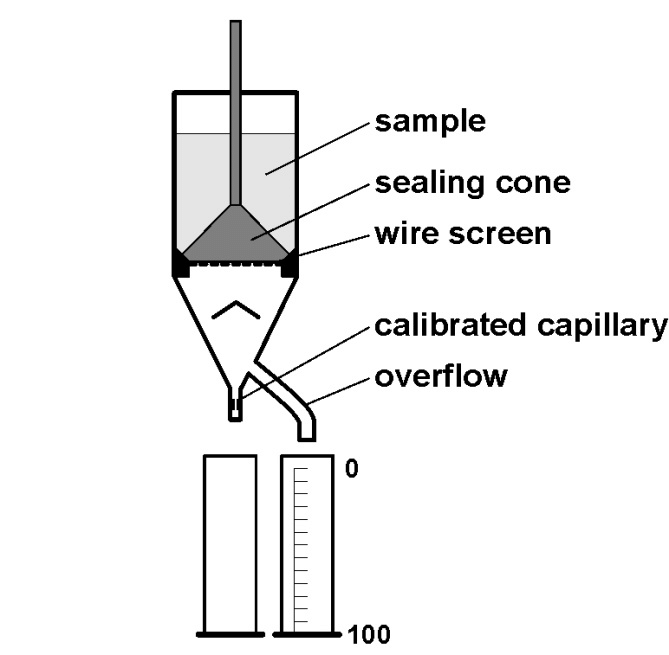

In paper mills, the degree of refining is often assessed by measuring the Schopper Riegler Degree (°SR), a parameter that reflects the degree of drainage of the pulp.

1.Specific energy consumption (E)

To control pulping, the first thing to do is to control the specific energy consumption (KWh/T), that is, to control the total energy consumption applied to 1 ton of pulp.

- E = (Pt – P0)/M

- Pt = Total power used in KW (electricity)

- P0 = No-load power in KW (power to turn the refiner: power loss)

- M = The mass of pulp passing through the refiner per hour, in tons/hour (T/h)

2.Specific Edge Load (SEL)

SEL, in W.s/m (or J/m), is the power transferred to the pulp (Pu = Pt – P0) divided by the length of the refiner cut per second, a parameter provided by the refiner manufacturer of the refiner (usually given in ICPM (inches cut per minute) or ICPS (inches cut per second) or KCPS (kilometers cut per second)).

- SEL = Pu/Ls

- Pu = Pt – P0, in Watts

- Ls: length of the refiner cut per second, in meters/second or KCPS (kilometers cut per second)

The rotation speed of the refiner affects the KCPS and therefore the SEL.

3.Specific surface load (SSL)

Specific surface load takes into account the width of the grinding blade (as shown in the figure above).

SSL, in W.s/m² (or J/m²), corresponds to the following formula:

- SSL = SEL/l

- SEL: Specific edge load (see above) in J/m

- l: Width of the grinding disc in meters

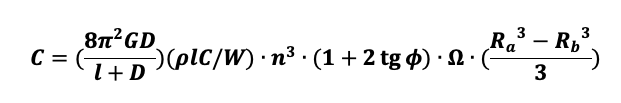

4.C factor

The C factor is relatively complex. This method takes into account the influence of all factors, including the number of refiners and the characteristics of the processed fibers (fiber length and thickness, pulp concentration).

The C factor method gives the number of refinements per fiber (N) and the intensity of each refinement (I) in µJ/time.

- N = C/F

- I = Pu/C

- F is the mass of pulp passing through the refiner per hour

- Pu = Pt – P0

For a double disc refiner, the C factor can be calculated using the following formula:

- G: distance between grinding strips

- n: number of strips per unit length

- D: depth of strips

- ɸ: angle of strips

- l: fiber length

- Ω: rotation speed of the refiner

- ρ: pulp density

- Ra: outer diameter of the plate

- Rb: inner diameter of the plate

- C: pulp concentration

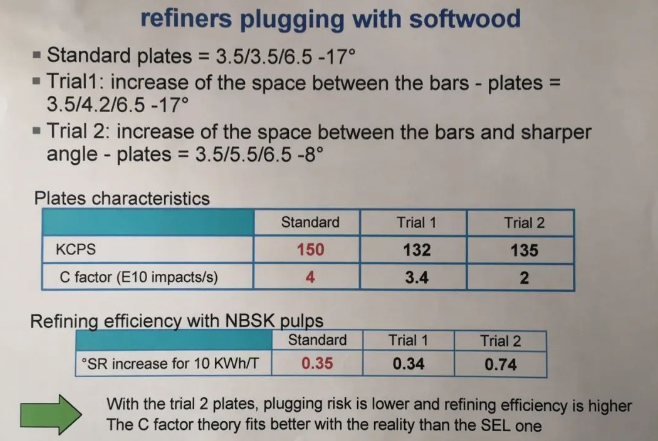

- W: fiber coarseness

The following pictures show the evaluation of the refining effect of the double disc refiner using the SEL and C factor methods respectively. It can be seen that the C factor can more accurately indicate that the refiner design used in test No. 2 is more suitable.